What a wonderful and traditional idea that children internalize when they hit their knees while learning to ride a bike and have now fallen down for the tenth time: Getting up once more than falling down brings success. What you learned back then can also be applied later in other situations, for example when you are repairing an assembly.

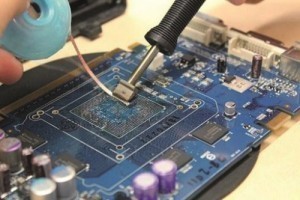

Replacing a poorly soldered BGA is particularly enjoyable. Not only do you need expensive equipment, but if you want to do it right the second or third time, it also takes a while - especially with quality-conscious companies that only allow one repair per BGA or even per assembly.  Fig. 2: Tools for removing a BGA

Fig. 2: Tools for removing a BGA

The development of ever larger BGAs with an ever increasing number of balls, the placement of more and more of these expensive components on and under and even in the PCB, makes this operation more delicate and tricky. Since the board has also increased in value at this point, there is a reluctance to simply dispose of it if it does not work.

The cost of a repair device varies enormously, but also depends on the user's attitude. If you simply want to get started with a hot air iron, a do-it-yourselfer can afford it. However, more sophisticated devices with computer control and nitrogen injection and a range of other options can be expensive.

Of course, this is not the end of the story, as you need additional equipment, tools and, last but not least, an X-ray system to check whether the next repair has actually been successful.

In addition to companies that specialize in repairing components and act as service providers, there are almost countless departments that also fiddle around more or less successfully. They are then the target group of the trainers who make sure that their employees learn how to do it right (for sure).

Once it has been discovered that one or two BGAs come out of the oven with faults during reflow - occasionally faulty BGAs that have found their way onto the PCB for 'inexplicable' reasons - the red flag goes up and the assembly is removed and perhaps stored.

The repair sequence is well known. The first step is to remove the component: After the assembly has dried out (usually at least 24 hours and possibly longer if the component is to be saved), it must be prepared so that only the faulty BGA is exposed to thermal stress. Removal without damaging the PCB or the component is not easy and becomes increasingly difficult with increasing size and complexity.

If the BGA has already been 'underfilled', this step becomes much more complicated and the question arises as to whether softening the plastic is sufficient or whether additional chemical and mechanical action is required.

Preparation of the landing surface and 'saving' the component: Once the component has been removed, the pads are no longer flat and applying paste would be more difficult. For this reason, the solder that is still adhering is removed using stranded wire or vacuum suction.

If the expensive or difficult to obtain component is to be saved, the balls must be removed and new ones soldered on - a separate step that is carried out elsewhere: do not overlook testing.

Applying solder paste: There are several options available to the specialist here. Mini stencils are one option if space is available and the specialist has a steady hand, dispensing is another and if a good, reliable device can be found, jetting could also be considered.

Alternatively or additionally, you can also apply paste or flux to the balls on the component. Fig. 5: 'Typical' BGA

Fig. 5: 'Typical' BGA

Attaching the component: This is not done by hand and suction tweezers but with a system that recognizes both the pads and the balls of the BGA by image and adjusts them mathematically. The contact pressure during placement is critical, as smearing or crushing the paste application will inevitably lead to a further repair.

Reflow soldering: As the heat should only be applied locally - neighboring components are sensitive - convection and possibly nitrogen are usually used. The thermal profile is considered critical and must take into account both the paste and the component. How to counteract local warping of the component and the PCB must be decided on a case-by-case basis.

Quality control: One of the most important steps is now the functional test and an X-ray inspection. Deciding whether the repair was successful or not is not easy and requires further knowledge and training.

Production runs are different and here we are talking about the quantity of goods that are produced every day. With 10 or 20 products per day, each containing one BGA, the situation is manageable. However, if 20,000 are produced, each containing half a dozen BGAs, the picture changes.

The repair of a larger BGA takes between 60 minutes and two hours, not including any drying in the climate chamber that may be necessary. This means that one worker can deal with between four and eight repairs on one machine during one shift. With several thousand soldered connections under a BGA, you have to ask yourself how low the soldering error rate has to be to avoid having to deploy battalions of workers on rows of repair machines. But this is exactly what we are now seeing in some productions.

From a quality and cost perspective, we should take a step back and ask ourselves: Why do repairs have to be carried out? Wouldn't it be smarter and cheaper to do everything right from the start, although 'zero defects' is of course also a chimera?  Fig. 6: Preparing the landing surface of a BGA with a soldering iron and stranded wire

Fig. 6: Preparing the landing surface of a BGA with a soldering iron and stranded wire

Admittedly, this is not easy. But a good manager - and process engineer - works very hard until he gets to the point where he has hardly anything left to do. That means learning and observing and working with everyone.

We know from mathematical game theory that cooperation models are far more successful than confrontation models - a scientific insight that has apparently not yet been accepted or understood by managers. The principle of such universities as 'Schools of Economics', which preach confrontation models and thus set the various departments on each other like hyenas, is wrong, which our politicians with (and without) plagiarized doctoral theses should perhaps also remember.

Getting everything right at the first attempt can only succeed if everyone works together in harmony. This is sometimes called 'people skill'.

References

[1] From William Hickson's 'The Singing Master' (1836): 'If at first you don't succeed, try, try again'

Prof. Rahn is a global consultant in connection technology.

Prof. Rahn is a global consultant in connection technology. His new book on 'Special Reflow Processes' was recently published by Leuze Verlag. He can be contacted at