Butter is the subject of much controversy. However, it is more beneficial to health than its bad reputation suggests. In addition, it has fewer calories than olive oil, which is touted as being so healthy. The only thing that has not been discussed is the question of how to achieve the right spreadability. The situation is similar with solder paste - not in terms of health or calories, but in terms of viscosity and rheology. There is also the question of shelf life. The solderer is initially faced with a mysterious sample [2], which he simply feeds into his printer without further testing. To ensure the final result, however, it would be advisable to obtain more detailed information about this mixture.

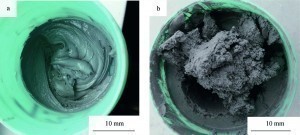

Fig. 2: a) Fresh solder powder b) Solder powder after paste storage (washed out)

Fig. 2: a) Fresh solder powder b) Solder powder after paste storage (washed out)

Solder paste is prepared from several additives, whereby a metal powder and activators - generally summarized under the keyword 'flux' - make up a significant proportion. A number of other additives are sometimes treated as secrets, although a chemist with a gas chromatograph should have little difficulty in identifying them.

Nevertheless, the manufacturers themselves seem to have certain difficulties, as faulty batches are not uncommon. They are then eliminated in subsequent tests and either recovered or sold with different properties than originally intended. This may explain some of the excessive prices that are charged, especially for very fine-grained pastes.

In addition to the activators in the flux, solvents such as alcohols or glycols are also added to make the paste printable. Various resins, for example, are used to provide the adhesion required to hold the components. Oxidation inhibitors and of course thixotropic chemicals - interestingly also derivatives of rhizinus oil - are also important because they allow stiffer pastes, which then behave more fluidly under shear.

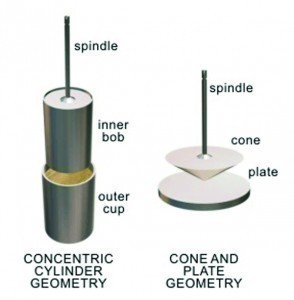

All in all, this is a rather unstable conglomerate, because not only are the weight differences between the metal and the rest of the mass considerable - manufacturers prefer to state the proportions as percentages by weight, because that is far more impressive than more relevant volume percentages - on the other hand, there are a number of chemicals sitting together for a long time that would very much like to react with each other, after all, that is precisely why they were selected. Fig. 3: Viscosity measuring device

Fig. 3: Viscosity measuring device

To slow down the precipitation of the metal particles, thickeners and stabilizers are mixed in, but these alone are not sufficient to prevent separation. This is why the paste should be cooled continuously, because the warmer it is, the thinner it becomes and the sooner the metal beads move downwards thanks to gravity. 'Continuous' here means uninterrupted, i.e. also during transportation, because if the stability is impaired even for a short time, the paste has already lost quality. A few hours unprotected in the seller's car trunk in summer and the paste has had it, as they say.

What 'cool' means here is specified differently by the individual manufacturers, but 7 °C ± 2 K is probably a guideline value. The thought naturally occurs to you, as with butter, to simply freeze it. This is possible with butter, although fresh butter has a more pleasant taste. Paste, however, has certain difficulties, because resin particles and other components of this concoction can crystallize, which is not a good thing.

Cooling also slows down the chemical reaction. If you concentrate on the activators, it is their task to combine with metal oxides to produce metal salts and thus release the metal surface for soldering. Although the powder manufacturers try to avoid oxidation of the grains by using covering gases (nitrogen) in 'most' (as they chastely admit [3]) steps, oxide skins are nevertheless formed.

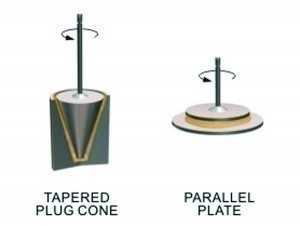

Fig. 4: Further variations for measuring viscosityNumerousstudies have shown thatpastes change in many ways during storage. There is disagreement as to what exactly is responsible for this.

Fig. 4: Further variations for measuring viscosityNumerousstudies have shown thatpastes change in many ways during storage. There is disagreement as to what exactly is responsible for this.

The reaction of the activators with the metal oxides on the solder balls certainly plays a significant role. But whether, for example, the break-up of some molecules or the reaction between additions make further contributions has not yet been investigated in detail by the chemists in the relevant industry, or at least not published.

Viscosity is one of the important properties of such pastes. It describes the viscosity of such 'liquids' and this is measured using various methods. A whole list of different instruments and devices can be found under the term 'viscometer' [4], so it is always advisable to check which method was used and at what temperature the test was carried out when specifying the viscosity, because the colder the paste, the firmer it is.

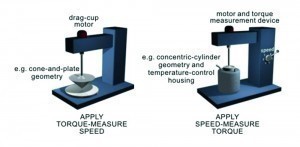

Fig. 5: Such devices monitor pressure, temperature and speed and can therefore also record thixotropic properties

Fig. 5: Such devices monitor pressure, temperature and speed and can therefore also record thixotropic properties

The measurement of rheology [5], which describes the flow behavior of the paste at different shear rates, is slightly different. As a variety of instruments [6] can also be used here, it is advisable to ask for data. Efforts are repeatedly made to prove a correlation between viscosity, rheology and paste pressure. However, with the exception of extremely thin or extremely thick pastes, there seems to be little usable data to predict the actual behavior of the paste. Too many other factors have an influence, not least the human factor, which continues to dominate this area of production due to the current lack of 'artificial intelligence'.

All good to know, but should the pastes be tested regularly?  Fig. 6: a) Mixed solder paste b) Ruined solder pasteAgood measurement of viscosity or rheology is quite complex and difficult and not really feasible in most companies. Larger manufacturers may have laboratories and well-trained staff to keep an eye on manufacturers and suppliers. Smaller solderers usually have no choice but to rely on the reliability of their paste companies.

Fig. 6: a) Mixed solder paste b) Ruined solder pasteAgood measurement of viscosity or rheology is quite complex and difficult and not really feasible in most companies. Larger manufacturers may have laboratories and well-trained staff to keep an eye on manufacturers and suppliers. Smaller solderers usually have no choice but to rely on the reliability of their paste companies.

Prof. Rahn is a globally active consultant in connection technology issues.

Prof. Rahn is a globally active consultant in connection technology issues. His new book on 'Special Reflow Processes' was recently published by Leuze Verlag.

He can be contacted at

Literature and notes:

[1] E. Marks: Characterization of Lead-Free Solder Pastes and their Correlation with the Stencil Printing Process Performance, University of Greenwich, UK, 2012

[2] C. Tudor: Minimizing Voiding;

[3] The Quick Pocket Reference for Tin/Lead and Lead-Free Solder Assembly, Aim, 2008

[4] General Information on Solder Paste, KOKI Company

[5] N. Badwe et al: Solder Paste: Fundamental Material Property / Smt Performance Correlation, Proceedings of SMTA International, Oct. 14-18, 2018, Rosemont, IL, USA

[6] F. Gao; D. Amin: Rheology Of Solder Paste: Shelf Life Study, Proceedings of SMTA International, Oct. 14-18, 2018, Rosemont, IL, USA

[7] F.V. Barbosa et al: Rheology Characterization of Solder Paste, ASME 2017 International Mechanical Engineering Congress and Exposition, November 3-9, 2017, Tampa, Florida, USA

[8] M. Holtzer et al: Using Rheology Measurement as a Potentially Predictive Tool for Solder Paste Transfer Efficiency and Print Volume Consistency, Proceedings of SMTA International, Sep. 25-29, 2016, Rosemont, IL, USA

References:

[1] https://www.kitchenstories.com/de/stories/butter-blitzschnell-weich-machen

[2] The term mush for a mash of fruit or vegetables goes back to the Old High German muos = food; meal.

[3] chaste from Latin conscius, 'conscious'

[4] https://en.wikipedia.org/wiki/Viscometer

[5] from ancient Greek ῥεῖν (rhein), German 'fließen' and λόγος (logos), German 'Lehre'

[6] https://en.wikipedia.org/wiki/Rheometer