The furor over whiskers that spread in the electronics industry following the introduction of RoHS (see NASA, for example) seems to have largely subsided. Although lead is now missing, which had also slowed down the formation of whiskers, among other things, the predicted catastrophe has - apart from a few isolated cases - failed to materialize.

The most prominent individual case: a pacemaker. But in this case, too, it was the housing and not a component. Whiskers formed on the tin-coated cover of the crystal and developed into conductive connections between the sheet metal and the crystal, which in turn led to the total failure of the pacemaker.

In 1951, Compton had already drawn attention to these small metal threads, which could potentially lead to failures in the electronics. Indeed, shortly afterwards, companies reported 'disasters' that were attributed to these metal threads. Most spectacularly, of course, NASA compiled a short list of such failures.

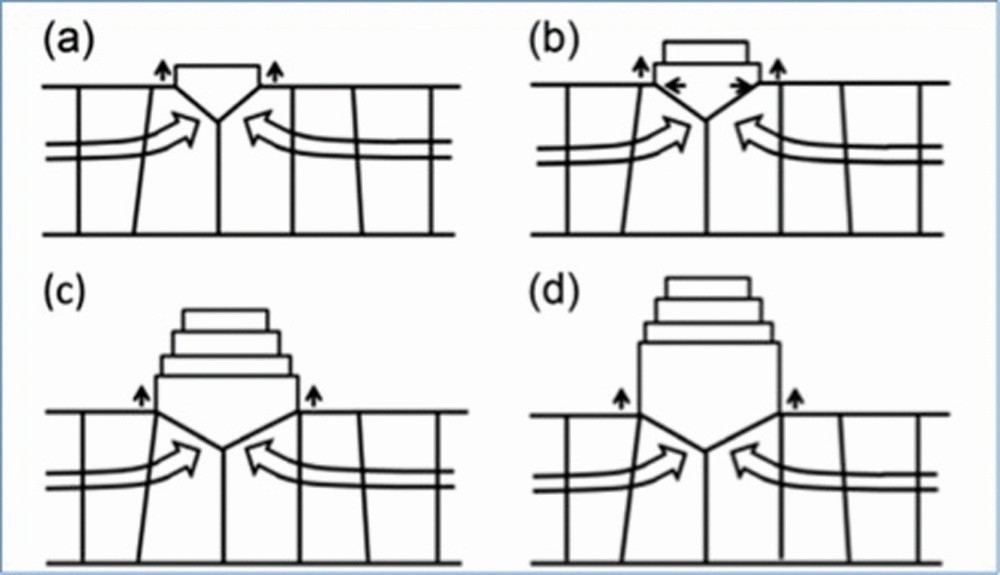

Formation of a hair crystal (according to Chason)

Formation of a hair crystal (according to Chason)

The case of the accelerator pedal at Toyota was widely reported in the press, where some experts attributed the reason for sudden acceleration to these 'whiskers'. This is what happens when 'fads' or money-hungry lawyers are confused with science, because as the NHTSA (National Highway Traffic Safety Administration) made unequivocally clear, no hair crystals could be proven [2] to be responsible for sudden acceleration. After even a $1 million award for the evidence was never claimed, the NHTSA determined that the true cause of the sudden acceleration was pedal misapplication. It was probably not the technology that failed, but the driver.

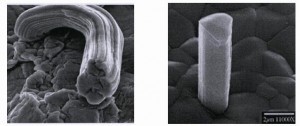

Examples of whiskers under the microscopeHair crystalshave been found for a number of metals. Tin is one of them - and the mechanism is now quite well understood. If tin is used, for example in coatings, whisker formation can occur. The metal fibers are squeezed out due to the pressure in the layers, because the increase in volume, for example in the formation of diffusion zones (Cu6Sn5), requires more space. Since in most cases the metals are too stiff to give way, tin, which is somewhat easier to deform, is pressed out. This pressure is also increased when the substrate is deformed (bending of connecting legs).

Examples of whiskers under the microscopeHair crystalshave been found for a number of metals. Tin is one of them - and the mechanism is now quite well understood. If tin is used, for example in coatings, whisker formation can occur. The metal fibers are squeezed out due to the pressure in the layers, because the increase in volume, for example in the formation of diffusion zones (Cu6Sn5), requires more space. Since in most cases the metals are too stiff to give way, tin, which is somewhat easier to deform, is pressed out. This pressure is also increased when the substrate is deformed (bending of connecting legs).

In addition, there is the realization that there is only a fairly narrow range in which tin hair crystals (normally) form: 25 to 60 °C. Below 25 °C, these crystals grow. Below 25 °C, these crystals grow only 'unwillingly', because the chemical-crystalline process is exceptionally slow. Above 60 °C, tin is soft and the compressive stresses are not sufficient to push tin out of the matrix. In addition, many experiments have indicated that growth usually takes a very long time, often several years.

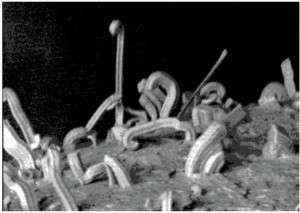

However, the crystals that are then formed are quite thin (1-2 µm) and rarely grow longer than a few millimeters (crystals up to 9 mm long have been grown under experimental conditions). The shape varies: straight, curved or even spiral. A 3-mm-long crystal has a resistance of around 50 ohms and burns out at a current of 10 mA.

In addition, the crystal filaments are brittle and break off easily when exposed to vibrations - all signs why they are unlikely to be the cause of problems such as those at Toyota.

Growth of a hair crystal on a coating (SEM photographs)

Growth of a hair crystal on a coating (SEM photographs)

Projections that they have caused up to US$10 billion in damage (as reported by NBC News) are more likely to be for managers or insurance companies than to reflect actual verifiable costs. Nevertheless, such figures are far more impressive than statements such as those offered by one of the major construction supply houses.

Hair crystals on tin (NASA)DfR Solutions in Sun City [3] reported that during 12 years of being in the component business, no case of hair crystals could be linked to standard components. All problems that they are aware of are due to non-standard parts, such as housings, specialty connectors, bus connectors, headers and other mechanical parts. According to their CEO Craig Hillman, not a single incident of whiskers on commercial off-the-shelf components such as SOIC, QFP, etc. has been reported.

Hair crystals on tin (NASA)DfR Solutions in Sun City [3] reported that during 12 years of being in the component business, no case of hair crystals could be linked to standard components. All problems that they are aware of are due to non-standard parts, such as housings, specialty connectors, bus connectors, headers and other mechanical parts. According to their CEO Craig Hillman, not a single incident of whiskers on commercial off-the-shelf components such as SOIC, QFP, etc. has been reported.

This suggests - if we are to believe such statements - that the methods now used to make it difficult for hair crystals to grow are working.

A lot of time, money and brainpower was spent trying to find methods to make the growth of these crystals largely impossible after lead was phased out by RoHS. Frustration was palpable and quite a few of the experts felt that the political decision to limit lead was a mistake.

The measures that have now been taken range from expensive to affordable. Most of them are carried out by the component manufacturer, but there are also some that can still be done by the assembler or solderer. None of the methods guarantee an absolutely crystal filament-free world, but many are sufficiently reliable that incidents, if any, are quite rare.

- It has been shown that an admixture of 5 to 10 % indium provides extensive protection against crystal growth when a tin layer is electrolytically applied to copper. However, care must be taken to ensure that the indium is evenly distributed in the Sn layer. Other metals such as bismuth are also useful

- A similar effect can be achieved by integrating Ni nanocylinders into the layer, which is somewhat more complicated. The effect depends on the thickness of the layer: at 1.6 µm it works, at 4.5 µm the effect fizzles out

- A nickel barrier layer is often used. 2 µm Ni then produces a diffusion layer Ni3Sn, which takes up less space than Cu6Sn5 and grows much more slowly

- Creating a thin NiO layer before applying the Sn layer also helps

- Instead of bright tin, matt tin should be used. The coarser crystal structure reduces 'whisker' formation

- The thicker the Sn layer, the lower the occurrence of hair crystals. A minimum of > 10 µm is suggested

- Ag can also be used as a barrier layer instead of Ni. This is less common because it is expensive

- With normal use, no 'whiskers' occur even on NiPd, NiPdAu and NiAu

- Shortly before use, Sn layers can also be annealed (24 h after coating at > 60 °C but preferably 1 h at 150 °C) or

- remelted in an oil bath or even replaced in a solder bath if necessary

- Pouring can also protect against 'disasters': e.g. Arathane 5750 (formerly Uralane 5750) prevents short circuits caused by hair crystals. The plastic material should appear on the pure tin with a thickness of 50 to 75 µm

- As mechanical stresses also promote crystal formation, care should be taken in the design to ensure that the differences in expansion coefficients are small

- Of course, the safest method - if feasible - is to avoid tin coatings.

So have some politicians once again cast out the devil with the Beelzebub in their decision to protect mankind from lead? Incidentally, in the electronics industry, which used only 0.5% of lead, this metal posed no health risk.

References:

[1] Montesquieu showed himself to be well-read when he dismissed an uprising in San Marino as "une tempête dans un verre d'eau", because Cicero already used the image "fluctus in simpulo" (storm surge in a ladle) in his De Legibus

[2] K.G. Compton et al.: Filamentary Growths on Metal Surfaces - 'Whiskers' Corrosion, October 1951, Vol. 7, No. 10

[3] https://nepp.nasa.gov/whisker/

[4] www.autonews.com/article/20120727/OEM11/120729908/nhtsa-rejects-tin-whiskers-theory-for-toyota-s-unintended-acceleration-incidents

[5] www.nbcnews.com/id/21151552/ns/

technology_and_science-science/t/danger-lead-free-electronics-tin-whiskers/

[6] 9000 Virginia Manor Rd #290, Beltsville, MD 20705, USA