The surface finisher De Martin, headquartered in Wängi near Winterthur, combines over 20 surface finishing processes under one roof and will soon grow to six plants. The expansion is being driven forward by Managing Director and owner Thomas De Martin. His company is a good address for all requests relating to functionalized surfaces - and is pursuing a stable growth course thanks to the diversity of its customer industries.

Top-level technology and expertise

Liaqat Nabawi inspects textile machine parts that are given a nickel dispersion coatingWhenit comes to high-tech and supplier companies with high standards, Switzerland has long been an interesting location: In the Alpine foothills between Lake Constance and the mighty massifs of the High Alps, universities such as ETH Zurich and the University of St. Gallen exude academic appeal, while research institutes such as the Swiss Federal Laboratories for Materials Science and Technology (Empa) conduct research at the highest level and continuously develop exciting innovations.

Liaqat Nabawi inspects textile machine parts that are given a nickel dispersion coatingWhenit comes to high-tech and supplier companies with high standards, Switzerland has long been an interesting location: In the Alpine foothills between Lake Constance and the mighty massifs of the High Alps, universities such as ETH Zurich and the University of St. Gallen exude academic appeal, while research institutes such as the Swiss Federal Laboratories for Materials Science and Technology (Empa) conduct research at the highest level and continuously develop exciting innovations.

But it is not just theory in which Switzerland can easily keep pace with its neighbors: Because production companies continue to exist despite top wage levels and the Credit Suisse crisis - albeit predominantly in the high-end sector for obvious reasons. Electroplating and surface technology companies are also among them. The high status of the sector is already indicated by the numerous relevant Swiss lecture events such as the Winterthur Surface Technology Day or the Technical Conference of the Swiss Society for Surface Technology (SGO) in Biel. Markets for surface technology include the watchmaking industry in western Switzerland, a flourishing medical technology sector and the nearby economically strong German states of Baden-Württemberg and Bavaria with their automotive and mechanical and plant engineering sectors.

De Martin, a company not far from Winterthur, also benefits from its proximity to Germany. Two electroplating plants with around 200 employees in the town of Wängi, population 5,000, coat parts for the semiconductor industry, textile machines, mold and tool making as well as the mechanical engineering and automotive industries in two and three-shift operation. The secrets of success are diversity in the customer industries and excellence in know-how, as quickly becomes clear. Around 50 of the 300 or so De Martin employees at the four plants in Germany and Switzerland are engineers or technicians with higher technical qualifications. People with a passion for electroplating technology and its various forms will be thrilled by the wealth of processes on offer. With over 20 different processes, De Martin offers functional coating solutions for corrosion protection, wear protection and reducing or increasing friction, and currently generates sales in the mid double-digit million range.

Managing Director and owner Thomas De Martin and CFO Karin Koller

Managing Director and owner Thomas De Martin and CFO Karin Koller

Coating technology without taboos

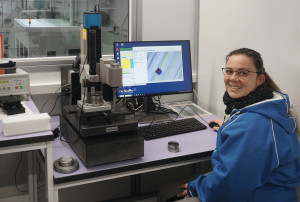

Just how much the surface technicians from Wängi are capable of can be seen right at the start of the tour in the company's own materials laboratory. Here, Alex Schellenberg, head of the De Martin technical center, is testing a dispersion coating with diamonds, the application of which is to remain a secret. Coatings of this type are used in toolmaking, for example. At De Martin, in addition to diamonds, boron nitride, boron carbide, PTFE and silicon carbide are embedded in dispersion layers. Alongside Schellenberg, his colleague Susanne Ribau monitors production on production line 5. While she reads off the measured coating properties on the screen, the highly specialized production in the lower part of the hall can be seen through a window. This is where the thin-film area with DLC, chrome nitride and titanium carbonide coatings, which are applied to the components using physical vapor deposition (PVD), is located. In order to optimize the functionality of surfaces, there are no taboos here: coatings are not only applied in a single layer or multilayer, but also as hybrid layers in combination with electroplated or electroless coatings.

Reducing dependencies through diversification

The fact that the dark-haired 45-year-old now heads a small group of surface technology companies is originally thanks to his grandfather, who immigrated from Italy. Trained in the nearby Sigg pan factory, he began electroplating everyday objects such as polished scissors and the mouthpieces of wind instruments in 1947. He later added pans, furniture, sanitary fittings, parts of coffee machines and textile machines, which were still being built in the Winterthur region in the middle of the last century.

When Thomas De Martin took over the business in 2004 at the age of just 26, he found a company that mainly manufactured for the textile industry. The young manager, whose educational background includes practical surface coating as well as management and business administration, thought it was too risky. "The textile industry is a very cyclical sector. We diversified quickly and also expanded geographically," Thomas De Martin looks back.

Today, the company manufactures for six sectors. The largest block, accounting for just over a quarter of the business volume, is the semiconductor and power electronics sector, followed by the textile industry and mechanical engineering. And the expansion continues: in the first half of 2024, an electroplating plant will open in Essingen in Remsstal and another plant is also to be built in Wängi. The specialty in Essingen will be coating with electroless nickel and electroless nickel dispersion coatings.

Creating properties with coatings

At the second plant in Wängi, just a few streets away, the baths for these coatings are now being built. De Martin has the greatest expertise here, and three of the current four plants use electroless nickel coatings. This surface coating is fundamental for the finishing of aluminum, for example, which is increasingly being used in automotive engineering due to its low weight. Electroless nickel is used, for example, to improve the load-bearing capacity of aluminum components in racing. To increase wear resistance, hard material particles are embedded in the electroless nickel layer. A PVD layer can then be deposited as a top coat to achieve a low coefficient of friction with high wear resistance. "The customer uses the good properties of aluminum and the coatings provide all the functionalities, such as corrosion protection, wear protection and good friction coefficients," says Thomas De Martin, describing the comprehensive possibilities of surface technology from his company. De Martin also uses electroless nickel to coat planet carriers for vehicles, electronic parking brake systems and belt tensioning systems.

Another component that Thomas De Martin takes from a carrier at the edge of the baths also has to be particularly wear-resistant. It is a plastic injection mold core that will soon be used in a special plastic injection molding plant in Eastern Europe for the production of PET plastic lids. Depending on the mold, 72, 96 or 128 lids are produced per shot of liquid plastic. The core is made of copper beryllium, the copper content of which is easily recognizable by the shiny reddish color of the component. "This is a butter-soft material that has the right heat-conducting properties, but would not be suitable for this purpose if it weren't for our coatings," explains the entrepreneur. A special hybrid layer gives the core the right adhesive properties as well as the necessary wear and corrosion protection to withstand the harsh conditions in the tool: The plastic is shot into the mold there in liquid form at 200 °C, cools and is then removed - every two seconds. "Wear is a huge issue today," emphasizes Thomas De Martin. "We can make a significant contribution to this by increasing the life cycle of components."

Tricking physics with process engineering

We move on to the wet chemistry laboratory, where Laura Fodor and Kathrin Fröhlich handle glasses in which a pink liquid sloshes. "We analyze the chemistry of the individual baths and see where the transition point is," explains chemist Kathrin Fröhlich. How a dispersion layer is created can then be seen in the factory, where an employee checks a goods carrier with parts for the textile machinery industry. In order for the particles to be deposited into the layer of electroless nickel by sedimentation, the components have to rotate. Large gear wheels, which help the suspended parts to rotate in the bath, are clearly visible on the edge of the carrier. The reason for the complex process is the weight of the particles, which are heavier than the electrolyte. They are kept in suspension by the movement of the bath and are then deposited. In order to have everything under one roof when it comes to surface technology, surfaces are also structured by laser at the De Martin Technical Center. Other processes include hard chrome, chromating and passivation.

With the acquisition of former competitor Novoplan in Aalen, the company has increasingly focused on the production of semiconductors since 2021. Apparently with success, as the workforce in the town on the edge of the Swabian Alb is growing and will soon reach 50.

Aalen, where De Martin maintains a research cooperation with Aalen University and specialist professor Timo Sörgel, is a favorable university location for recruiting skilled workers. However, the search for skilled workers is not easy in view of low unemployment figures and a massive "upward wage spiral". Thomas De Martin therefore employs an employer branding manager who is responsible for employee development, job attractiveness and incentives. A pleasant working environment with social rooms and air-conditioned production is also important in the new buildings to convince interested parties of the Swiss coating all-rounder.

Switzerland - an island of bliss?

And what's next for De Martin? The conditions for family businesses in Switzerland are generally good and, despite the restrictions on the movement of goods imposed by non-EU member state Switzerland, production and cross-border business are feasible given the current status quo. The number one business partner is Germany, followed by the rest of Europe and, in some cases, North America and Asia. Meanwhile, competitors are also based in Japan and Singapore. Looking to the future, the father of two sons aged 13 and 15 sees light and shade: He believes that the supply chain difficulties caused by coronavirus and the war in Ukraine have been overcome because the situation regarding the price and availability of hydrochloric acid, caustic soda and sodium hypophosphite has now eased somewhat. However, he is concerned about EU developments such as the ban on combustion engines from 2035 and a "disastrous" energy policy.

Looking through the large windows of the De Martin headquarters, it becomes clear that the impression of everlasting stability, prosperity and quality of life suggested by the panorama of gently rising green mountain pastures in the distance is deceptive. The complexity of the changing globalized world has long since found its way into this supposedly tranquil corner of Central Europe. Thomas De Martin's recipe: "Nothing is as constant as change, we have to develop rapidly - ideally faster than the market."