The economy is changing due to the energy transition, among other things, and the industry is undergoing a transformation process. In order to meet customer and market requirements as an innovative partner, MacDermid Enthone is constantly working to identify new trends and develop adapted technologies.

"We use a global network of experts and a wide range of technologies to offer specific solutions for the electric vehicle market, hydrogen production, solar technology, wind turbines, etc. - and not just in the field of electroplating and surface technology," says Christian Kaiser, Business Director for Central and Eastern Europe at MacDermid Enthone.

New components, new requirements

The automotive industry is one of the most important industries in Germany and is also changing at a rapid pace. National and international competitive pressure is increasing, but the opportunities arising from this transformation process serve as an innovation booster for MacDermid Enthone customers and OEMs. Components installed in electric vehicles offer new areas of application for coating technologies (see table).

|

Heat sink |

Cooler |

Fuel cell |

Busbars |

inverter |

Compressor |

|

|

Type of application / type of parts |

Thermal semiconductor management, PinFin in glycol |

General thermal management and heat exchange |

Bipolar plates and frames |

Busbars made of copper and |

Semiconductor thermal |

Electrical |

|

Function / property |

Corrosion resistance, solderability, |

Prevention of galvanic corrosion |

Compressive stress EN, low metal leaching |

Corrosion resistance, solderability |

Corrosion resistance, solderability |

Abrasion resistance, |

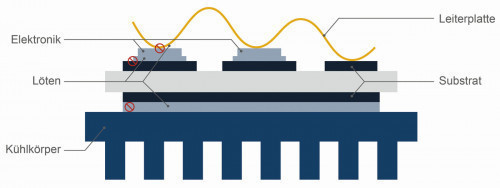

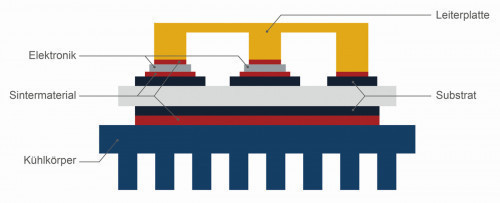

The inverter is a key component in electric vehicles. To prevent it from overheating, heat management using heat sinks plays an essential role. The coated heat sinks are then connected using soldering or sintering processes.

Example of an electric vehicle at a charging station

Example of an electric vehicle at a charging station

The demands on the functionality and durability of components in electric vehicles are increasing due to ever higher charging currents and physical stresses. This requires the use of soldered or sintered materials for high-temperature applications.

"Everything from a single source"

At MacDermid Enthone, the improvement of thermal management is realized through the development of innovative processes for coating heat sinks and electronic components. In addition, the connection technology for subsequent soldering or sintering is also developed and produced in-house (MacDermid Alpha). The clear advantage for customers is that they have a central point of contact for all processes, i.e. "everything from a single source".

A prerequisite for high quality sintering processes:

Electroless nickel, silver and optional tarnish protection serve as preparation for the subsequent soldering or sintering process.

MacDermid Enthone pilot systems for coating prototypes:

Prototype coating takes place in the MacDermid Enthone pilot plant. Customer samples undergo a validation process after coating.

Alpha Assembly Solutions Tech Center for sintering, soldering and testing:

In in-house soldering or sintering facilities, components can be joined using our proprietary technologies and then tested.

Combined expertise and proven results:

Coating experts are in constant communication with application specialists to jointly drive the innovation process and deliver the best possible results.

Sustainability

Sustainability is a top priority at MacDermid Enthone. The focus is on using environmentally friendly materials to develop innovative processes. Conserving resources and reducing waste help to reduce theCO2 footprint.

Battery production

Battery production is both a complex and future-oriented topic and does not only affect the automotive industry. The development of new coatings for battery anodes is a decisive factor in terms of longevity and efficiency.

Innovative coating processes

"We have a comprehensive range of innovative coating processes that offer effective solutions for the ever-evolving electrification landscape. Properties such as uniform coating distribution, excellent corrosion resistance and effective wear resistance are just some of the fundamental aspects of our coatings," says Helmut Horsthemke, Global Product Line Director Wear Resistant Coatings at MacDermid Enthone.

EMC (electromagnetic compatibility)

In the field of EMC, MacDermid Enthone develops processes for shielding the components that are connected to the on-board electronics in the car. This is known as shielding. The plastics used for this must be individually conditioned before metallization in order to guarantee optimum adhesion of the metal layers to the substrate - MacDermid Enthone also offers technological solutions for this.

Looking to the future with MacDermid Enthone

Looking to the future with MacDermid Enthone

Looking to the future together!

"We assure our customers that we are the partner at their side, regardless of the economic situation. Strong partnerships, a high level of expertise and innovative processes are our approach in this time of change," says Bob Geissler, Vice President Europe at MacDermid Enthone.

Get in touch with us. Benefit from our extensive portfolio for new applications, our expertise and our broad OEM network.

Better together. MacDermid Enthone.

Pictures: MacDermid Enthone, AdobeStock