Munk GmbH supports surface technology companies on their way to a climate-friendly future. Investing in more efficient plant technology usually involves a large sum of money. In cooperation with energy consultants, Munk GmbH raised a total of over 500,000 euros for its customers in 2022.

Munk called on the competence and expertise of Öko-Zentrum NRW from Hamm for energy consulting. As an independent company, the Öko-Zentrum has numerous certified energy consultants in its own ranks. In addition to specialist technical advice, the customer receives extensive support in applying for subsidies. It has proven to be a good idea to be able to fall back on experts in the field of subsidies. For some years now, the BAFA (Federal Office of Economics and Export Control) has been subsidizing the investment of high-efficiency rectifiers in the Federal Republic of Germany. BAFA has five funding modules under the heading of energy efficiency, which are used for federal funding of projects for energy and resource efficiency measures.

Funding for rectifiers falls under Module 4, the energy and resource-related optimization of systems and processes. In principle, this involves the optimization of industrial and commercial systems that contribute to reducing energy consumption and avoiding carbon dioxide (CO2) emissions. In order to apply to BAFA for a subsidy, a savings concept must be drawn up. The savings concept is therefore the basic application document.

Assumption of up to 40 % of the costs

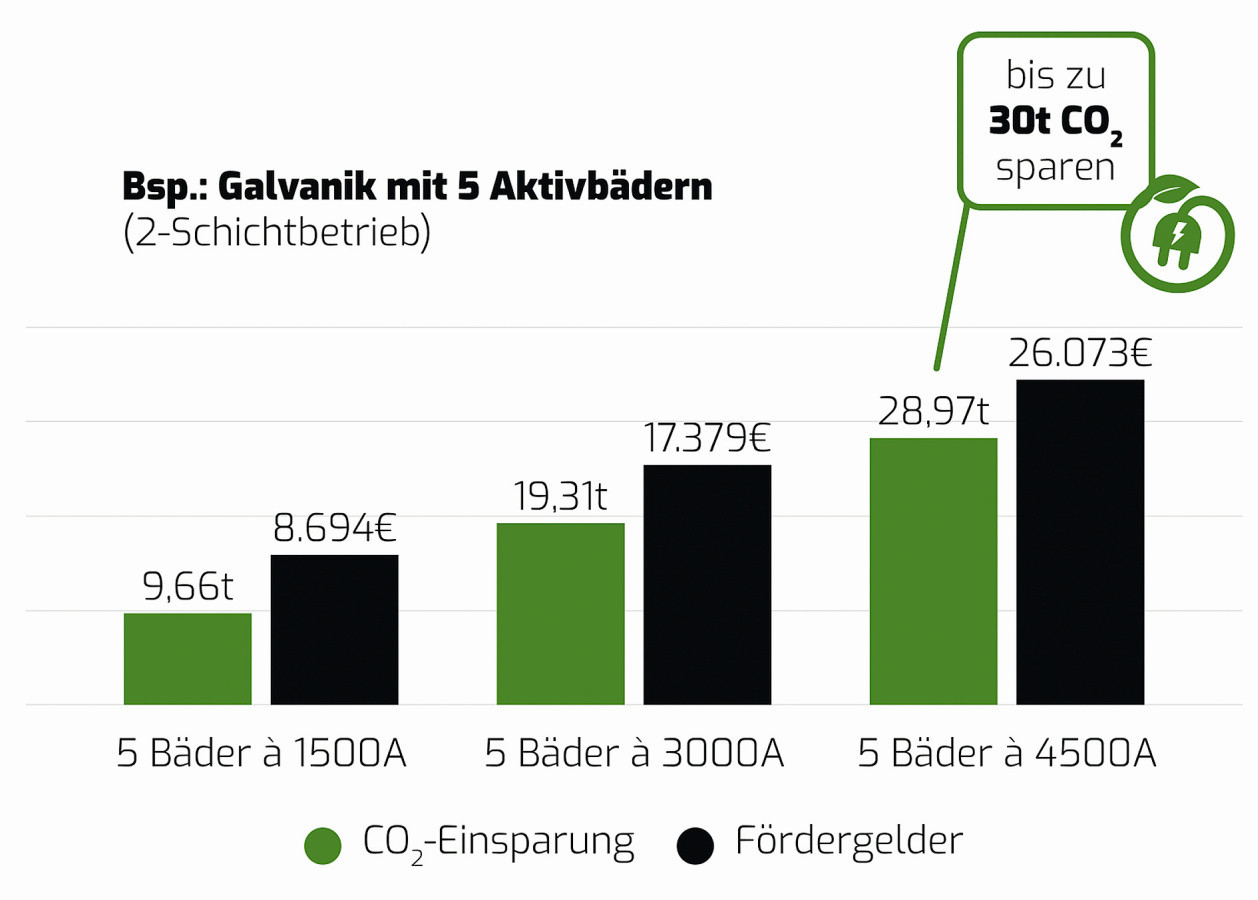

Module 4 funding can be granted as a one-off BAFA grant or as a low-interest loan with a repayment subsidy via KfW. The basic prerequisite is that the efficiency measure is implemented within Germany and that the appliances are operated for the intended purpose for at least three years. Furthermore, the subsidization of rectifiers is linked to certain framework conditions. The object of the subsidy must therefore lead to energy and resource savings within an installation. The aforementioned savings concept must be drawn up by a BAFA-certified energy consultant. In addition, the investment project must not pay for itself within three years without claiming a subsidy, otherwise it will not be classified as eligible. The basis for calculating a subsidy amount is the conversion of a kilowatt hour (kWh) into the weight of carbon dioxide (CO2). BAFA issues specificCO2 factors for the various energy sources. If we consider electricity as an energy source, then theCO2 equivalent for 1 kWh corresponds to around 0.732 kg ofCO2. If you save one kilowatt hour of electricity, you also reduceCO2 emissions by 0.732 kg. BAFA therefore subsidizes every ton ofCO2 savedwith 900 euros for small and medium-sized enterprises (SMEs). For non-SMEs, it is 500 euros per ton ofCO2. BAFA is prepared to cover up to 40% of the eligible costs for an investment. In addition to the costs for the rectifiers, the installation of the new appliances and dismantling of the old appliances as well as the energy consultant's energy-saving concept are eligible for funding.

Energy optimization

An existing system includes rectifiers that have been in operation for at least 10 years. Old systems, on the other hand, are defined by rectifiers that have already had a service life of > 25 years. Experience has shown that the savings potential for old systems is many times higher, as rectifier technology has developed enormously in recent decades, regardless of the technology. In order to maximize efficiency potential, Munk GmbH is now presenting its latest rectifier innovation, the gamma L3+. It impresses with an increase in efficiency compared to the current market standard. In addition, the output current has been increased to 1800 A per module, although the weight and design have been retained. The retention of the design is a key function here. The engineers paid explicit attention to this aspect during research and development, as this ensures that existing systems can benefit from the new development. Furthermore, the increase in efficiency results in energy cost savings of at least 4 %. Savings of up to 1.2 kW per hour can be achieved when converting to Munk rectifiers. The calculation of the savings is based on an output power of 24 kW (e.g. 16 V / 1500 A).

Funding project for existing system

As part of an efficiency measure, an increase in efficiency of +5% was achieved at a surface coater. A total of nine rectifiers with different performance data were replaced. These were primarily devices for a zinc rack system. In a 3-shift operation, the company produces approx. 6,000 hours per year. The target/actual comparison shows an actual energy saving of around 162,000 kWh per year. It is noticeable that despite the supposedly small increase in efficiency, the operating times are decisive for the immense savings. The amount ofCO2 saved is required for a possible subsidy. The 162,000 kWh are equivalent to over 118 tons ofCO2. As an SME, the company is happy to receive a subsidy of 900 euros per ton. In principle, over 100,000 euros in funding would have been possible, but the so-calledCO2 cap of 40% applies to this project. Compared to the investment sum of 240,000 euros (including ancillary costs), the possible subsidy amount is above the 40% mark. At 32 cents per kilowatt hour (price mid-2022), energy cost savings of just under 57,000 euros per year are secured. Taking the energy cost savings into account, the subsidy project will achieve an amortization period of less than 36 months after the subsidy funds have been used.

Funding project for old system

The second exemplary funding project was submitted at the beginning of 2022 and subsequently implemented. The customer (SME) operates the system in 2-shift operation. In contrast to the previous funding project, this modernization measure involves retrofitting an old system. Some of the appliances are over 40 years old. It is quite possible, as in this example, that some rectifiers now only have efficiencies of 60-70% due to age-related degradation. The efficiency potential here is well over 20 percentage points. In the automatic system, a total of seven active baths in a drum system were refitted. The new, more efficient rectifiers, including the dismantling of the old appliances and adaptation work in the low-voltage distribution system, entailed an investment of around 140,000 euros. The 133,000 kWh of energy saved corresponded to more than 97 tonsof CO2. The subsidy amount was therefore well over 40% of the total costs, meaning that theCO2 cap was applied. In the meantime, the energy price for a kilowatt hour has doubled to 0.35 euros due to new contracts. With annual energy cost savings of 45,000 euros, the remaining investment sum after deduction of the subsidy has already paid for itself within 24 months. Regardless of the size of the project, it can be said that the amortization period for subsidized projects is in the range of 1-3 years.

www.munk.de /