parts2clean 2023: High purity with AI and robot technology Intense expert discussions, a successful expert forum and a positive atmosphere on all three days of the trade fair. This year's 20th parts2clean from September 26 to 28 welcomed around 3,000 trade visitors. They were confronted by 150 exhibitors from 14 countries with state-of-the-art technologies. Some of these were particularly impressive, as a tour of the trade fair showed.

Cleanliness is playing an increasingly important role in more and more industrial sectors - this is the conclusion that can be drawn at the end of the 20th parts2clean, both nationally and internationally. The proportion of visitors from abroad was around 20%, with the strongest visitor nations being Germany, Switzerland, the Czech Republic, Turkey, Austria and the Netherlands. The highlight theme "High Purity", which was added to the core areas of the leading international trade fair for industrial parts and surface cleaning for the first time this year, contributed to the increase of around 33% compared to the previous year. "As a result, we have placed a stronger focus on the range of solutions offered at parts2clean for tasks where the highest cleanliness requirements must be met," reports Christoph Nowak, Project Director at Deutsche Messe AG.

The foreign share was around 20%

Investments at the trade fair

In total, more than 150 exhibitors from 14 countries presented new, enhanced and proven products and services for industrial parts and surface cleaning on around 4,500 square meters. Business deals were also concluded, as Wolfgang Prem, Managing Director of Maschinenbau Silberhorn GmbH, reported: "The highlight of our participation at the trade fair was that we were able to sell one of our new MWS cleaning systems to a company from Israel directly at our stand. It was a first contact that came about here at the trade fair."

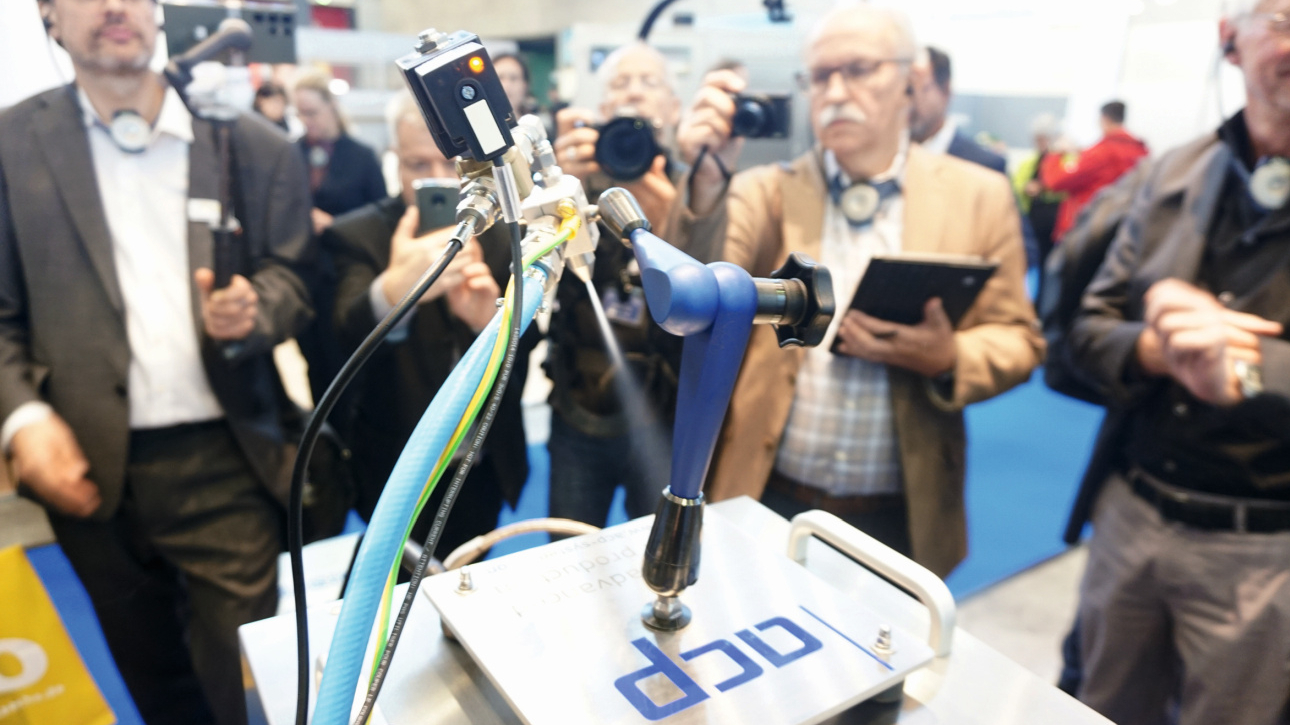

Partial cleaning with electric arc and argon

Maria Laure from the Austrian company Fronius International GmbH demonstrated her company's Acerios cleaning process with the exemplary cleaning of an aluminum surface. Cleaning is usually carried out with the help of a special robot cell in which an electric arc and argon gas are used for cleaning. The process is already in use at Audi. The car manufacturer partially cleans surfaces where bolts are inserted. The arc is virtually blown out during the cleaning process. The process works using a tungsten electrode and plasma nozzle. Fronius also took part in the Fit2Clean competition with the cleaning solution and achieved 3rd place.

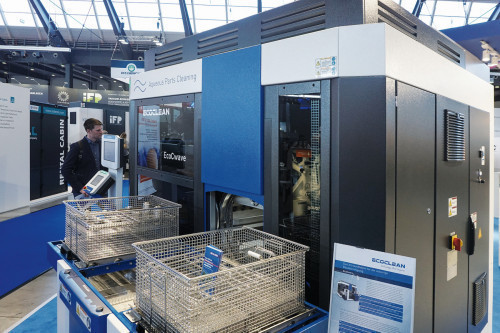

"Gigantic effort" for maximum cleanliness

Reiner Straub from Ecoclean, which was one of the 18 companies highlighted by the trade fair organizers as part of the focus topic High Purity, presented the UCM Smartline system at the company stand, in which highly complex assemblies are cleaned with extremely clean water, among other things. On display was a compact system with three baths in which the components to be cleaned are placed in large metal baskets. In practical use, the systems have 9-0 baths, as Straub described. Cleaning includes processes such as drying, baking and degassing. Sometimes the cleanliness requirements are so high that only particles of 1 nm are allowed. Black light is also used for this in order to be able to find the particles at all. It is a "gigantic effort" to guarantee technical cleanliness with these requirements, Straub pointed out.

Fraunhofer Institutes demonstrate AI-supported parts cleaning

Frank-Holm Rögner - Fraunhofer FEP (Institute for Organic Electronics, Electron Beam and Plasma Technology) - gave a tour of the Fraunhofer Society's stand with numerous new developments

Frank-Holm Rögner - Fraunhofer FEP (Institute for Organic Electronics, Electron Beam and Plasma Technology) - gave a tour of the Fraunhofer Society's stand with numerous new developments

The Fraunhofer Institutes are also developing numerous cleaning processes. Eight institutes presented themselves at parts2clean, divided into the areas of high purity, analytics, processes and training. The Fraunhofer IPA (Institute for Manufacturing Engineering and Automation) presented an automated test stand for technical cleanliness.

The Fraunhofer IPM (Institute for Physical Measurement Techniques) presented a fluorescence analysis with a fluorescence scanner. The light used detects particles and residual contamination.

The Fraunhofer IVV (Institute for Process Engineering and Packaging) presented an AI-supported parts cleaning system. The system can decide in the background which cleaning processes are recommended, which should make cost savings possible.

The Fraunhofer IPK (Institute for Production Systems and Design Technology) showed a system for cleaning with liquid CO2, which is bundled into a jet. This cleaning method is said to have a high dissolving capacity for heavy localized soiling and can also be used in parallel with laser or textile cutting, for example. The technology can also be used to clean the back of components.

Finally, the Fraunhofer IWS (Institute for Material and Beam Technology) presented a solution for cleaning in battery cell production.

Water-based cleaning fluids

Dr. Alexander Breul from Intelligent Fluids (FiT2Clean Award 1st prize) presented innovative cleaning agents. His motto: "The best chemistry is no chemistry "Intelligent Fluids is a partner of the Fraunhofer Institute. The company won the FiT2Clean Innovation Award, endowed with 10,000 euros, for the development of water-based, sustainable phase fluids that can replace conventional solvents in numerous cleaning applications. The German Industrial Parts Cleaning Association (FiT) honored outstanding achievements and solutions for parts cleaning for the second time in 2023. Dr. Alexander Breul presented the cleaning emulsions that impressed the FiT jury. The key innovation: the fluids contain no chemicals and can be used in a wide temperature range from boiling to melting. The company entered the development of cleaning agents in 2006 with a graphite remover.

Dr. Alexander Breul from Intelligent Fluids (FiT2Clean Award 1st prize) presented innovative cleaning agents. His motto: "The best chemistry is no chemistry "Intelligent Fluids is a partner of the Fraunhofer Institute. The company won the FiT2Clean Innovation Award, endowed with 10,000 euros, for the development of water-based, sustainable phase fluids that can replace conventional solvents in numerous cleaning applications. The German Industrial Parts Cleaning Association (FiT) honored outstanding achievements and solutions for parts cleaning for the second time in 2023. Dr. Alexander Breul presented the cleaning emulsions that impressed the FiT jury. The key innovation: the fluids contain no chemicals and can be used in a wide temperature range from boiling to melting. The company entered the development of cleaning agents in 2006 with a graphite remover.

Dr. Alexander Breul - 1st Prize Fit2Clean Award

AbrasiveCO2 snowflakes

acp systems AG was also one of the High Purity exhibitors. Their snow jet cleaning solution - also based onCO2 - removes particulate and filmy soiling, e.g. grease and fingerprints, as Verena Braun demonstrated. The fully automated system, which originally comes from the medical technology sector, produces abrasive snowflakes that are each around 0.5 μm in size.

Other exciting technologies included a particle suction system from Clean Controlling, which is used in dry production areas, e.g. in electric cars, where it monitors cleanliness, and the systems from Surface Alliance, which clean components down to a technical cleanliness of 3 μm.

Record numbers at the specialist forum

The trade fair organizer spoke of record attendance at the specialist forum.

The trade fair organizer spoke of record attendance at the specialist forum. 2,700 participants took part in the simultaneously translated (German <> English) presentations by renowned speakers from science, research and industry to generate or deepen their cleaning knowledge. "The enormous popularity shows that there is an immense need for information for both classic cleaning tasks and high-purity applications, which will continue to increase due to changing and new requirements," said Christoph Nowak from Deutsche Messe.

Industrial Parts Cleaning Association

The Industrial Parts Cleaning Association also offered presentations at its stand. The highlight on the last day of the trade fair was the presentation of the FiT2clean Award. In addition to Fronius (3rd prize) and Intelligent Fluids (1st prize), the company Sphera Technology GmbH also won with an innovative solution for monitoring technical cleanliness in the micro and nano range. New at FiT: The drying guideline for component cleaning.

Photos: Robert Piterek