electronica' made an impressive return - with 2144 exhibitors, 70,000 visitors according to the trade fair and a lavish supporting program. The conferences, forums and special events such as the CEO Roundtable attracted a great deal of interest. According to Dr. Reinhard Pfeiffer, Managing Director of Messe München, exhibitors and visitors were more satisfied than ever before in the trade fair survey [1]. The PLUS editorial team was also on site.

In fact, the atmosphere was excellent. After the Covid-19 years, during which the electronics trade fair had to retreat into a virtual snail shell, there was a sense of relief and joy. At last, it was once again possible to talk face-to-face about business, content and private matters, and the 14 lavishly equipped halls offered space for professional exchange and newly forged collaborations. The automotive sector was a particular focal point - it is the focus of many expectations and promises business success and innovation.

The PLUS editorial team was represented by seven members, refreshed existing good contacts, made numerous new ones and held stimulating and interesting discussions. Naturally, we spread ourselves out strategically in order to 'take away' as much as possible from our experiences. Accordingly, Markolf Hoffmann (editor-in-chief), Gerald-Schwager-Ränner and Rolf Nagl (both advertising editors) report on their experiences in this issue; the impressions of editors Gustl Keller and Werner Schulz on 'electronica' and 'SEMICON' will follow in the January issue.

Cost-cutting measure or commitment to sustainability? The lack of carpets in the exhibition halls was a much-discussed topic

Cost-cutting measure or commitment to sustainability? The lack of carpets in the exhibition halls was a much-discussed topic

Prototypes every week

BMK presented a new online portal for the efficient creation of prototypes at 'electronica': BMKyourproto is the name of this ambitious platform - and it aroused our interest. At the stand, graduate engineer Tim Sievers, Head of Operations at BMK, presented the portal as an innovation. The aim is to use BMKyourproto to manage the entire project from OEM development to the EMS production approach in a targeted manner and with maximum data security in order to deliver prototypes in quantities of up to 20 units to the customer 'from a single source'. The aim is to be able to access the availability of components and their delivery times at any time - especially in times of faltering supply chains. Ideally, the prototype series could be delivered after just seven working days thanks to such optimization. Sievers referred to the first enthusiastic customer experiences, although the go-ahead has of course only just been given. Hopefully we will soon be able to report on practical experience with the portal and find out whether BMK meets the high expectations.

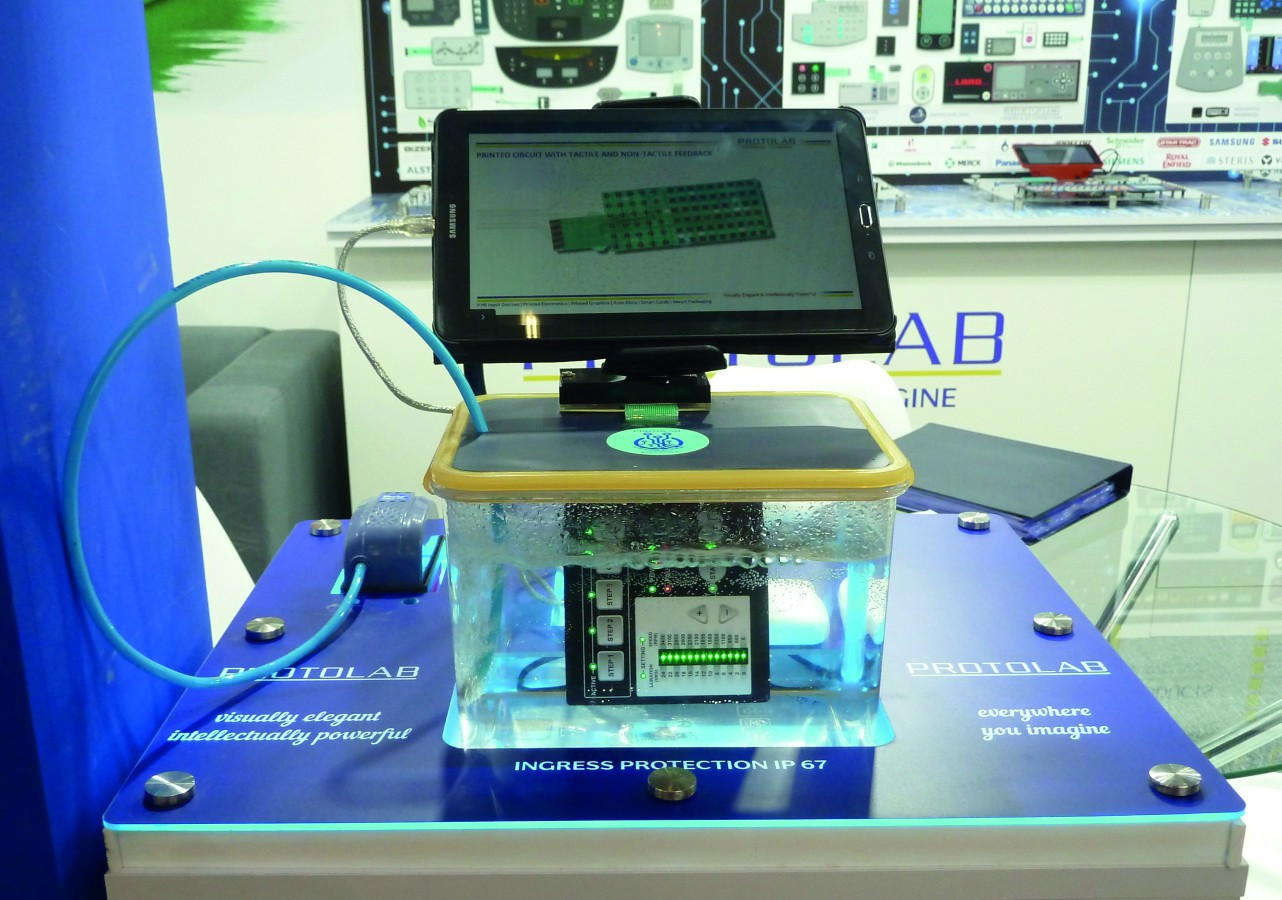

Fig. 5: Protolab from India sends electronics under water

Fig. 5: Protolab from India sends electronics under water

New investment in Austria

An exciting conversation took place with Andreas Gerstenmayer, CEO of AT&S. The PCB manufacturer from Austria, which Hayao Nakahara ranks 11th among the PCB producers with the highest turnover in the NTI 200 Report 2021 (issue 10/22), has recently been able to present excellent figures. In the first half of the 2022/23 financial year, turnover exceeded EUR 1 billion for the first time, and despite the volatility of the current market situation, AT&S has announced further investments. In particular, a new R&D center with associated production for substrates and advanced packaging, which the Austrians are building at their headquarters in Leoben, Styria (investment sum: € 500 million), caused a sensation.

We wanted to know why the choice fell on the domestic location. A commitment to the Austrian and European market? Not necessarily: Gerstenmayer gave PLUS pragmatic reasons. AT&S had examined several options for the R&D center in detail, especially in the USA, but then decided on Leoben. The company is already sufficiently well positioned in Asia, especially with its plants in China and Malaysia, where large series in the areas of IC substrates and mobile devices are manufactured. In Leoben, employees from numerous nations have been recruited, intercultural workshops are held for the religiously and culturally diverse workforce and an association is involved in an international school that aims to attract more skilled workers to Styria. Around 700 employees are expected to make up the workforce there. However, not all jobs have been filled yet.

We also spoke to Gerstenmayer about current concerns in the industry, such as the rise in energy costs. The AT&S Chairman expects this to ease in the medium term. He was more critical of the subsidy programs in Austria and Europe as a whole; here he would like to see a more comprehensive commitment. Overall, AT&S intends to establish an entire production chain for small series in Austria - as a counterpart to the large series in Asia.

So no 'reshoring' - but AT&S is pursuing the recognizable goal of optimizing its position as the top PCB producer in Europe. This is probably one of the reasons why the company was at 'electronica' this year - to show its presence, according to Gerstenmayer.

Green socks and lollies with a QR code in Hall B1

PCB manufacturer KSG, which manufactures in Germany and Austria, also made its presence felt. According to Katharina Luchner, Senior Marketing Manager, and Sebastian Seifert, Head of Key Account & Export, this will remain the case: KSG is not currently planning any further plants abroad. The commitment to the European region is also based on conviction. KSG seems to want to make this visible: The 'electronica' stand largely dispenses with the display of products. The focus is on personal contact, Luchner tells us, and not just the PCB itself, but also the corresponding applications. The Gornsdorf-based company is significantly expanding its range of services, focusing on customer proximity and establishing a series of XPERTS seminars for the online sector. All of this seems well thought out and authentic - which is why KSG's efforts towards sustainability are also impressive, as demonstrated by the commissioning of a copper recycling plant (see Interview of the Month, p. 1728). Last but not least, the focus described by Luchner was demonstrated by the trade fair stand.

SecureAR

An augmented reality project for industrial use was on show at the stand of the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP (Dresden). The AR assistance system for the provision and visualization of data in industrial processes, which is funded by the Federal Ministry of Education and Research and several companies, has been under development since 2020 and aims to improve working conditions and production processes, for example in aircraft construction or electronics production. We had FEP department head Bernd Richter demonstrate the AR helmet to us and put it on ourselves - the superimposition of real view and superimposed data is already astonishing, even if questions remain regarding wearing comfort, motion sickness and data provision. We will be presenting the project in more detail in an upcoming issue.

Successful trade fair days

The encounters described above are of course only a small part of our trade fair experience. The pictures we were able to take at the trade fair are a testimony to the commitment and the brilliant atmosphere of the exhibitors and visitors.