Question: Over the last 20 years, our quality assurance has grown with the size of the company and the growing demands of the automotive industry, for example. Every few years, we try to simplify, automate and better organize our documentation. What once began with simple complaint processing now runs through all levels of the company. Internal rework, equipment failure, problems, occupational safety issues and many other areas are recorded, documented and assigned to the appropriate people.

We have now reached a point where managing the documents - usually very long Excel spreadsheets - is just as problematic as the actual search for recorded data. We have tried to map part of it in the ERP, but it seems like a tool that is only inadequately suited to our requirements. Do you have any suggestions for affordable solutions to this problem that are suitable for everyday electroplating?

Answer: What you describe is a common problem in small and medium-sized companies - not just electroplating companies. Twenty years ago, quality assurance was a necessary evil in many companies, the aim of which was to do away with itself. Over time, awareness of this has changed and it has been realized that the methods can be applied far beyond complaints and 8D reports.

What has remained in many cases is the documentation dilemma. The demands have grown and it is no longer sufficient to list which problem occurred when.

There are three main difficulties:

- Mapping the entire operation as accurately as possible. This applies to departments, people, groups of people, procedures and much more.

- Good searchability of the data. The more complex the mapping (point 1) and the more facts are recorded, the more difficult it is to find what you want in a short space of time.

- Access to the data. In most cases, it should not only be possible to access the data internally, but also externally with the appropriate rights. There may need to be interfaces with customers and partners. In addition, it should be possible to access the data on as many devices as possible.

These three points give rise to additional requirements. Data needs to be analyzed. Statistics should be generated. Automatic notifications about tasks, status etc. are just as necessary today as a system in which not only the beginning and end, but also the intermediate steps can be fully documented.

Document management

A central point is the handling of digital documents. Most companies with more than a handful of employees now have an internal server for storing files in addition to numerous PCs. It has proven useful to divide the structure according to two aspects.

- Employees

- Divisions / departments

The purpose of organizing according to personnel is to ensure that the documents created are stored on the server and not locally on the PC. Virtual drives are used for this purpose. Although this is slower than a local SSD, for example, it simplifies the handling of backups considerably, as these can be carried out centrally and automatically.

The second point is a more difficult decision and depends on the size of the company, among other things. The data can be divided into areas such as complaints, work instructions, environmental technology, etc., or by department. The larger the company, the more it is subdivided by department and then by area. For example, there are several folders on the entire server with the name "Work instructions", each of which relates to a specific department.

With further growth, the problem then arises that documents are created multiple times and there are different versions. As these versions can be overwritten, it is easy to lose track of them and it is no longer possible to display a reasonable history (keyword: version management).

The task becomes more challenging if you have several locations, possibly some of them abroad, and they even work in different languages.

Document management systems (DMS)[1, 2] are available for companies of all sizes to help you get to grips with this.

For smaller companies, we recommend a free wiki system, with which you can already do a lot. For this, you need a web server that can be implemented both internally and externally. MediaWiki [3] is the best-known database-based wiki. This is used by Wikipedia. If you want to do without a database, we recommend DokuWiki [4]. Wikis primarily facilitate the handling of internal documents. Instead of writing work instructions in Office and exporting them as a PDF, for example, you can type in the texts directly and have version management with you. Both wikis can be adapted to individual requirements with numerous plug-ins.

Error and event documentation

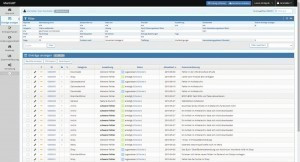

The user interface of MantisBT, which is also used by Leuze-VerlagHerewe recommend a tool from software development: Bugtracker. It sounds strange at first, but these programs essentially do exactly what is required in modern companies.

The user interface of MantisBT, which is also used by Leuze-VerlagHerewe recommend a tool from software development: Bugtracker. It sounds strange at first, but these programs essentially do exactly what is required in modern companies.

In a bug tracker, you can first create projects. A project can be a specific process, a department or an area. You can create as many users as you like and give them different rights. In addition to administrators, there are so-called reporters who enter errors and events, for example. This can be further classified. Entries can be assigned to persons. The processing of the entry can be documented step by step, for example through comments, attachments, etc.. This means that every step can be traced afterwards. The entries also have a status that changes as they progress. The result is perfect documentation with minimal effort.

Example: You have the project "Zinc plant". You select "Solving station" as the category as you want to create a corresponding entry. You specify whether the error is reproducible, what effects it has and how high the priority is. To keep an overview for later, write a one-sentence summary. This is followed by a more detailed description of the problem, followed by steps for reproduction and additional information. If you wish, you can add tags and attach documents such as photos. Now assign the entry to a responsible employee. This person is informed of the problem by e-mail and receives a link to the bug tracker.

Any number of people can work on an entry. The bug tracker automatically records every processing step and records this in an entry history. Here you can always see who changed what and when. If you record changes via comments / notes, you have perfect, complete documentation of events.

Good bug trackers have excellent filter functions. If you set them up accordingly, you can filter by customers, procedures, time periods, clerks, error patterns, etc. Even statistics are generated automatically. Even the statistics are generated automatically. As they run in the browser, they work on any modern device. Many bug trackers also have smartphone apps so that you can be kept up to date anytime and anywhere[5, 6]. This idea can also be used to set up a ticket system for your customers [7].

This allows you to record not only errors and problems, but also suggestions for improvement. These can be discussed within the system. At the end, you can track why certain ideas were accepted or rejected. We are already using MantisBT - partly in a modified version - in electroplating plants. At Leuze Verlag, it is also used for websites and projects.

Links

[1] https://www.dmsfuehrer.de/

[2] https://www.dmssoftware.de/

[3] https://www.mediawiki.org/

[4] https://www.dokuwiki.org/

[5] https://www.mantisbt.org/

[6] https://www.bugzilla.org/

[7] https://www.helpdesk.com/