Question: Over the last six months, there have been repeated problems with our wastewater treatment. This is reflected in increased metal levels in the final inspection, particularly nickel and zinc. Although the wastewater system is a little outdated, it works perfectly. The resins on the final exchangers were replaced a year ago and nothing has changed in the production processes. Only production was shut down due to the pandemic. We are now only working one or two shifts instead of the previous three.

We do not use cyanides or alloy electrolytes. Only zinc, acid copper, nickel, chromium(VI) and tin. The chromium(VI) is reduced in a separate treatment tank before metal precipitation.

What could be the reason for the sudden problems? How can the detoxification process be improved?

Answer: The treatment of galvanic wastewater is a complex issue and can rarely be improved with general tips. It usually requires several samples of the wastewater, analyses, laboratory tests with optimizations and then implementation in the treatment tank. Nevertheless, we would like to give you a few suggestions so that you can help yourself.

Sampling and analysis

Poor flocculationYoudescribe that the values in the final control chamber are too high. This suggests that the control in the treatment tank is OK and that the value only becomes higher later (see below). Another conclusion would be that the sampling and the resulting analysis are not in order at least at one of the two measuring points. This is the easiest to inspect and should be questioned regularly anyway, as errors always occur in routine tasks carried out by humans.

Poor flocculationYoudescribe that the values in the final control chamber are too high. This suggests that the control in the treatment tank is OK and that the value only becomes higher later (see below). Another conclusion would be that the sampling and the resulting analysis are not in order at least at one of the two measuring points. This is the easiest to inspect and should be questioned regularly anyway, as errors always occur in routine tasks carried out by humans.

First check whether the same methods are used for measuring at both locations. Electroplating companies like to use rapid tests in the treatment tank, but photometric tests in the final control shaft. The results are not comparable, especially if the sample is cracked before measurement.

It is also important to ensure that the samples are taken at the same time. Equal quantities in identical, clean containers. The container should be rinsed several times with the sample liquid before sampling to make absolutely sure that there are no external influences. If it is a sealable bottle, the lid must be taken into account when cleaning and rinsing. Salts that remain as residues from previous samples can greatly distort the measurement result.

The final control sample to be analyzed must be thoroughly mixed before removal. At the sampling point, it must be ensured that the mean value of all substances to be analyzed is present.

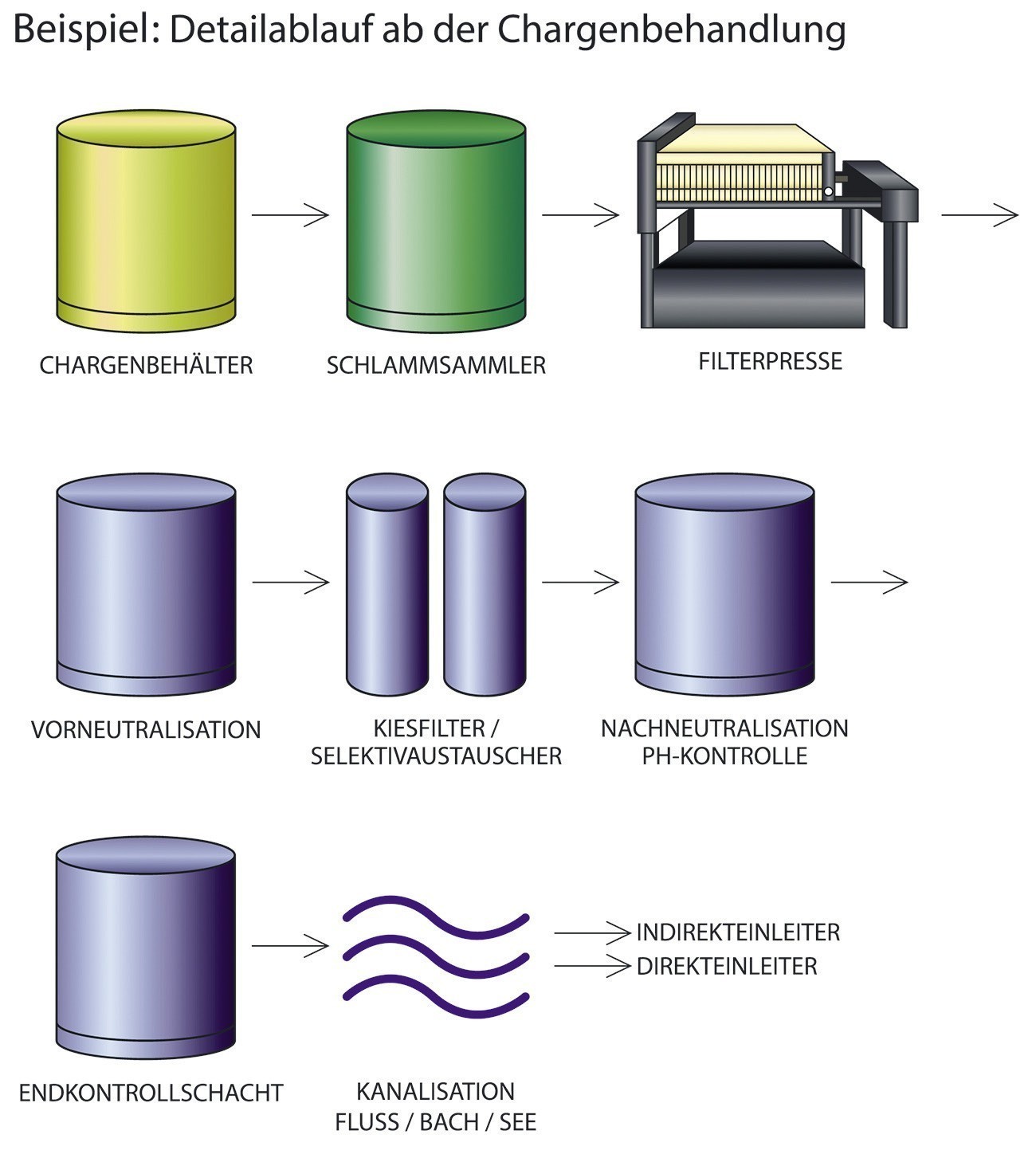

Checking the subsequent processes

If the difference persists, the downstream processes must be checked. This primarily includes the filter press and final exchanger, but also the piping and treatment basin in between. We recommend cleaning everything completely. Especially due to the lower production and lower wastewater load you mentioned, which we assume, downtimes can lead to crystallization and thus local concentration of metals. These are dissolved during the next cycle and lead to higher values.

You should also check whether the regeneration of the final exchanger is working properly. It is quite possible that the flow rate or other controls were adjusted when the resins were replaced, meaning that the system is no longer working properly. We would even go so far as to check whether there are any resins in the exchanger at all.

Less wastewater

Wastewater treatment works best when the same initial concentrations are always produced in the same cycle. Reducing the load by 50 % or more can have a major impact on wastewater treatment, as it cannot be assumed that the initial concentrations will be the same.

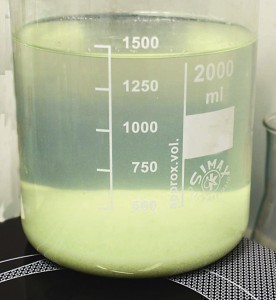

In practice, it has often been shown that the rinse water is more diluted in such phases because relatively more rinses are changed than in three-shift operation. This has an effect on the concentration of salts in general and metals in particular, which often makes metal precipitation more difficult.

In this case, the addition of salts such as calcium chloride helps to shift the balance towards precipitation. In addition, calcium ions themselves bind anions such as fluorides and phosphates.

General tips for wastewater treatment

Good flocculationTheprecipitation result isusuallybetter if different metal ions are detoxified together, as the precipitation range shifts positively in the presence of several types of ions. If 2 metals are precipitated together from a solution, the solubility of both precipitates is lower than if they are precipitated separately at the same pH value. The higher the initial concentration of the other metal, the lower the solubility of one metal precipitate. The influence of the trivalent metals on the solubility of the precipitation product of the co-precipitated second metal is greater than that of the bivalent metals. However, this changes when the total concentrations increase and the hydrolysis products are no longer present in their voluminous form with the active surfaces.

Good flocculationTheprecipitation result isusuallybetter if different metal ions are detoxified together, as the precipitation range shifts positively in the presence of several types of ions. If 2 metals are precipitated together from a solution, the solubility of both precipitates is lower than if they are precipitated separately at the same pH value. The higher the initial concentration of the other metal, the lower the solubility of one metal precipitate. The influence of the trivalent metals on the solubility of the precipitation product of the co-precipitated second metal is greater than that of the bivalent metals. However, this changes when the total concentrations increase and the hydrolysis products are no longer present in their voluminous form with the active surfaces.

The decrease in solubility during the joint precipitation of the metals is due to the following causes:

- Formation of mixed crystals, especially between the bivalent metals.

- Formation of compounds, especially between 2- and 3-valent metals, e.g. chromites.

- Adsorption of metal ions, which can only be precipitated at higher pH values, on the active surfaces of the precipitates, which already form at low pH values, especially adsorption of bivalent metal ions on the hydroxides of the trivalent metals.

This can be different in the presence of amphoteric metals. Especially if the pH value of the redissolution is below the target value. Zinc, in combination with nickel, causes fewer problems, as the redissolution value is 10.8. Tin (9.2), aluminum (8.7) and chromium (8.3), on the other hand, are critical.

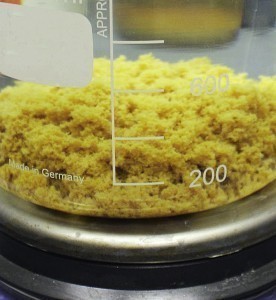

The size of the flocs can be a problem, especially if there are problems with the filter press. This can already be observed during the flocculation process and subsequent sedimentation.

Before precipitation occurs, supersaturation must take place. This is followed by conditions that are to be expected according to the solubility product.

First crystallization nuclei are formed, which then grow together to form large crystals (or particles). The rate of nucleation is decisive for the formation of the crystallization nuclei. The faster the supersaturation occurs, the greater the rate of nucleation. At a constant temperature, which can be assumed for the neutralization of diluted wastewater, the nucleation rate depends on the low solubility of the substance to be precipitated and on the reaction rate.

The ions forming the precipitate attach themselves to the nuclei formed, forming more or less ordered crystal lattices. The speed of this process, the crystallization speed (crystal growth speed), depends on the diffusion speed of the ions and thus on their concentration gradient.

Between diffusion to the surface of the nucleus or crystal and incorporation into the lattice, adsorption takes place on the surface.

Optimal precipitation takes place in three steps:

- Alkalization or addition of precipitants. The pH value is first increased with Ca(OH)2, then with NaOH up to the end point (usually 9-9.5).

- Addition of flocculants. This is usually done with FeCl3 or Al2(SO4)3 (coagulation).

- Addition of flocculants (flocculation).

Coagulation is the destabilization of finely dispersed to colloidal systems by eliminating their charge on the surface. The latter is the reason why the particles cannot approach each other and combine to form larger particle clusters.

The interfacial charge is neutralized by adding electrolytes, the effect of which increases approximately exponentially with increasing valence. If the electrolytes consist of solutions of slightly hydrating metal salts, e.g. FeCl3 or Al2(SO4)3, as is usual in the coagulation of wastewater constituents, then not only do they coagulate, but adsorption processes also occur. This combination is called adsorption coagulation. If these metal salt solutions are added in excess, the fine particles are also mechanically incorporated into the coarser iron(III) hydroxide or aluminum hydroxide flakes, thereby improving sedimentation.

Flocculation is a process that often follows coagulation, but can also be used on its own. This is particularly the case if the agents used are ionogenic and therefore also lead to coagulation. Organic macromolecules with an elongated structure, which are water-soluble and can attach electrostatically or chemically to colloids or very fine particles, are suitable for flocculation.

It is important that the macromolecules adhere to the particles at one end or lengthwise and that the other end reaches as far as possible into the electrolyte. This can then attach another particle in the same way.

This results in larger clusters held together by these thread-like molecules, which are easy to sediment or accelerate sedimentation. Substances that cause such flocculation are called flocculants.

It is important to stir for only as long as necessary after adding these flocculants. Stirring for too long can lead to the long-chain molecules being broken up again.