Question: Due to the acquisition of a piece of land, we now have the opportunity to expand our electroplating facility by at least one more system. As this is our core business, it will be a barrel system, but we would like to expand our range of processes. There are three new coatings to choose from, for which we still lack the necessary in-house expertise. However, all three processes will probably be integrated into one system.

As we lack practical experience, we would like to start with preliminary tests on sheet metal and small objects in the laboratory, but we do not know how well such tests can be transferred to practice. We need general tips to get the best possible assessment.

Answer: Introducing three new processes because you have the space to do so sounds a bit like trying to complete an incomplete scrapbook. We assume that the commercial side of this has been thoroughly examined. Even if it does not correspond to the question, we would first like to address difficulties that may arise within the system.

System planning

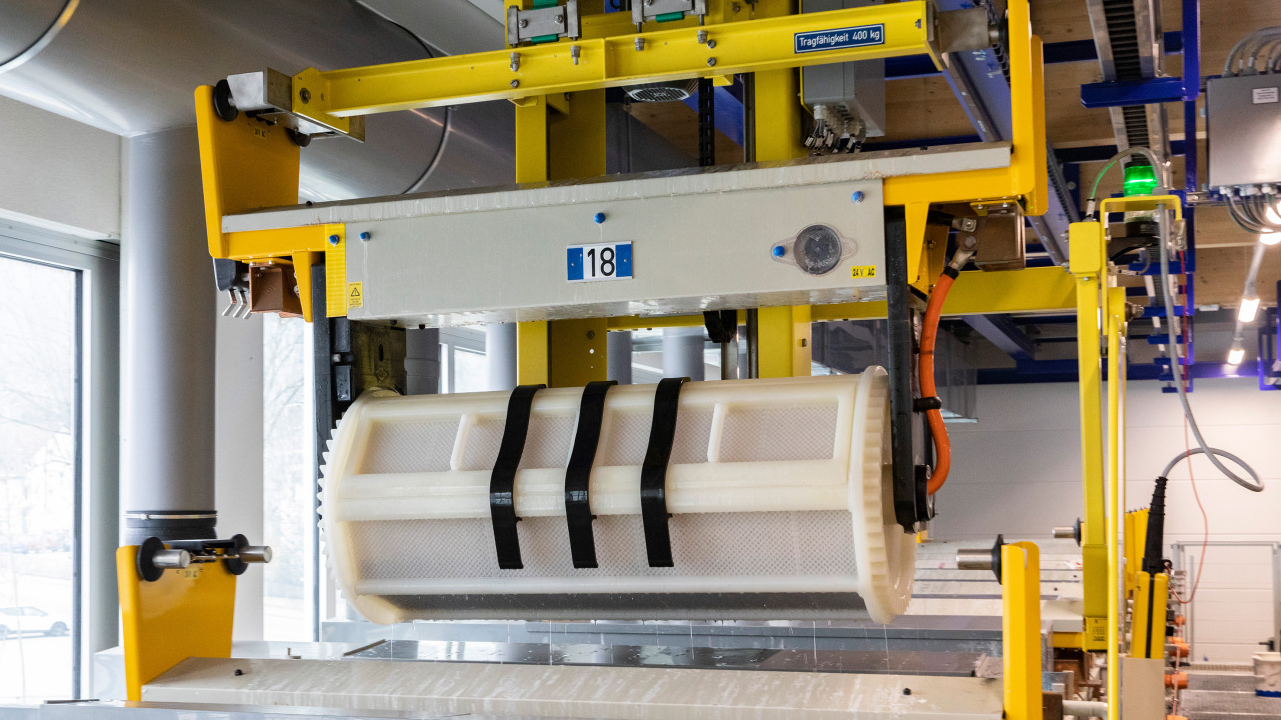

Plant technology of the drum plant at a glanceSinceyou have not told us which processes are involved, we are currently assuming an "arbitrary" combination.

Plant technology of the drum plant at a glanceSinceyou have not told us which processes are involved, we are currently assuming an "arbitrary" combination.

First of all, the chemical composition of the electrolytes as well as pre- and post-treatment must be taken into account. In addition to possible space problems, compatibility must also be taken into account. There are also difficulties with the waste water, complex pipework, etc.

Carry-over is a major issue. When combining various processes, there is a tendency to save on rinsing, which can inevitably lead to problems such as poor rinsing quality and possibly undesirable chemical reactions. For example, if you combine bright nickel with alkaline zinc electrolytes and these may share the flow rinse. Under unfavorable conditions, flakes of nickel hydroxide can form. Not to mention the carry-over of zinc electrolytes into a nickel electrolyte.

For this reason, the trend is to build systems with several lines. In this way, the coating processes share the same pre-treatment, but are otherwise completely self-sufficient. The lines are connected to each other via a cross converter.

The problem here is coordination, which can and will lead to bottlenecks. When planning pre-treatment, the starting point is the actual state, which is often idealized. Over time, the delivered goods deteriorate, e.g. become more oily, which extends the pretreatment time. This leads to electrolytes in which there is no product, which makes the plant unprofitable. The problem is not only found in the pre-treatment, but also in the coating itself. It is extremely rare for a system to have three different processes working at the same time, i.e. one or two coating processes are often in sleep mode, but you have to heat or cool all three.

We would therefore recommend a maximum of two processes that are compatible with each other. For example, zinc and zinc-iron. For other combinations, we recommend smaller systems with mono processes. In addition to the points mentioned above, this also has advantages in terms of maintenance, dismantling and conversion as well as downtimes, etc.

Scalable tests

The problem of scalability is well known. Whether in the electronics or automotive industry, everywhere it is found that only a few properties/behaviors can be transferred 1:1. This also applies to the development of electrolytes. These are created in a Hull cell, continue in a beaker, 5 liter tank, etc.

Depending on the process, even optical properties may turn out differently in practice than in the laboratory or on a small scale.

Properties in the laboratory

In the laboratory, you can determine both the chemical properties and electrochemical principles.

In addition to the isolated observation of an electrolyte, you can also experiment with impurities/carryover and rinsing behavior. For example, you can determine how problematic or unproblematic certain amounts of carryover are.

In addition to general coating properties, the effects of impurities, overdosing, etc. can also be excellently determined on Hull cell sheets. Depending on the coating process, such as tin or silver, an angled cathode is even preferred.

Practical tests

The best results are obtained when the tests are carried out in a manually operated small system. Although this requires an additional investment, the system can later be used for small series, sampling and training.

Tubs with a volume of 20-50 liters and corresponding hanging drums are suitable. This allows the surfaces to experience the key physical parameters, such as drum rotation and subsequent drying in a centrifuge. Depending on the part geometry, properties such as depth scattering and gloss can be assessed much better than with a beaker in the laboratory.