Displaying items by tag: coating

Anodic oxide coatings are formed on the metallic job by an electrochemical process known as anodizing. The process is carried out in an electrolytic cell where a job is made of an anode and a suitable inert metal as a cathode (Figure 3.1). When the electric current of sufficient voltage is passed through a suitable electrolyte the metal surface is converted to an adherent oxide coating which is an integral part of the substrate [1–4].

Chemical conversion coatings are one of the most common surface modification techniques that provide a barrier between metal and its surrounding environment [1]. The treatment can be carried out by dipping, spraying or by application of brush. The term chemical conversion is used where the exposed metal surface gets converted into the chemically inert inorganic coating by a chemical or electrochemical process. The coatings, in addition to corrosion protection, may impart requisite functional properties, enhanced surface hardness and a good base for application of subsequent paints, lubricants, adhesives, etc. The properties of these coatings depend on the kind of substrate metal, the composition and structure of the coatings. On the other hand, the composition and structure of the coatings depend on the bath composition and operating parameters of the process.

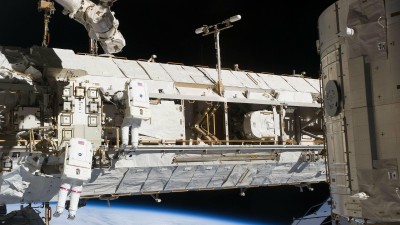

Besides aesthetic look, black finish on metallic substrates are used for various technological applications. Black coatings exhibit strong absorbance for a wide range of incident angles and are therefore extremely important to suppress stray light in the optical systems. Black coatings are abundantly employed as passive thermal control technique to maximise the thermal radiation in parts and devices.

Evonik teilt sein umfangreiches Know-how über Farben und Lacke mit der gesamten Coatings- und Druckfarben-Industrie: Auf COATINO® Campus bietet das Geschäftsgebiet Coating Additives Neueinsteigern und Experten gleichermaßen umfangreiche Informationen über Additive und Formulierungen. Auf der neuen Wissensplattform finden sich unter anderem umfangreiche interaktive eLearnings zu Effekt-Gruppen wie Entschäumer oder Mattierungsmittel, Live-Events, Experten-Vorträge, Labor-Videos und vieles mehr. Die Registrierung und Nutzung der Plattform ist komplett kostenlos.

The paper covers the study of the structure and properties of rhodium coatings obtained by pulse current from an aqueous electrolyte solution containing no surfactants. The authors determined the optimal parameters of the pulse current that forms finer-crystalline, dense and hard coatings. The use of pulse unipolar current made it possible to obtain high-quality rhodium coatings without the use of surfactants.

Evonik stellt einen neuen Kieselsäuretyp aus der AEROSIL® Produktgruppe vor: VP 4200 ist eine strukturmodifizierte Kieselsäure mit freien OH-Gruppen, die den Einsatz von umweltfreundlicheren, kupferoxidhaltigen Anti-Fouling-Beschichtungen ermöglicht.