Displaying items by tag: coatings

Die Geschäftseinheit Oberflächentechnik des Unternehmensbereichs Coatings von BASF, die unter der Marke Chemetall operiert, hat am 13. Februar die Eröffnung ihres neuen globalen Aluminium-Kompetenzzentrums in Giussano, Italien, gefeiert. Das hochmoderne Zentrum soll die Position von Chemetall als globaler Lösungsanbieter für die Oberflächenbehandlung von Aluminiumsubstraten weiter stärken.

Der Unternehmensbereich Coatings von BASF hat eine neue mehrjährige globale Industriepartnerschaft mit WorldSkills International unterzeichnet. Mit dieser Vereinbarung setzt BASF ihr langjähriges Engagement für die Förderung neuer Talente in der Autoreparaturlackindustrie fort und bekräftigt ihre Unterstützung für den nächsten globalen WorldSkills-Wettbewerb, der im Oktober 2022 in Shanghai stattfinden wird.

With optical surface quantification methods doped and undoped carbon coatings deposited by Laser Arc Technology are analyzed. The article shows, that by producing doped carbon coatings using composite cathodes also a significant reduction of arc-induced particle emission is observed. A surface evaluation method, particularly developed for this purpose, shows a significant reduction in particle area coverage. Part 1 covers the origins of growth defects, methods of surface characterization and the experimental setup and measurement methods.

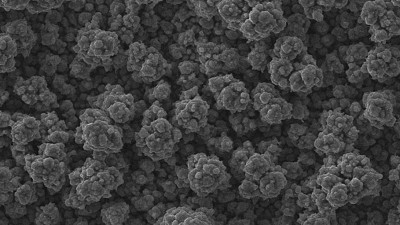

What awaits you in this article: Hybrid Zn-Mn(11 wt.%) alloy coatings containing in their matrix stabilized polymeric micelles (SPM) are electrodeposited from a sulfate bath. SPM are added to the electrolytic bath in concentrations of 0.1 or 0.3 wt.%, respectively. The coatings are additionally treated in Cr(III)-based solutions for obtaining of surface conversion layers (CL) aiming at receiving of better corrosion resistance. Surface morphology of the hybrid coatings (with or without additional conversion layer) is presented by SEM. The protective characteristics are evaluated with potentiodynamic polarization (PD) and polarization resistance (Rp) measurements in a model corrosion medium of 3% NaCl solution. Experimental results demonstrate the better corrosion resistance and the greater protective ability of the hybrid coatings obtained from electrolyte with 0.1 wt.% SPM, compared to the ordinary Zn-Mn alloy.

Plasma electrolytic oxidation also known as micro arc oxidation (MAO) or spark anodization is a relatively new surface modification technique. The process is used for growing thick, and hard oxide coating on light metals and alloys such as Al, Mg, Ti [1-5]. In principle, the process is similar to anodizing but involves the use of higher voltages and is carried out with mild aqueous alkaline electrolytes [6–17]. In this process, plasma discharge occurs which leads to partial fusion of an oxide film and consequently formation of an extremely adhesive oxide coating on the substrate [18].

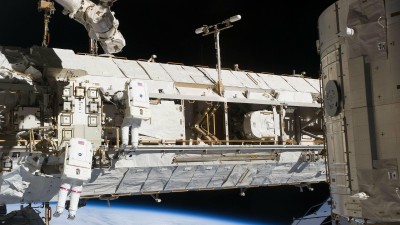

Electroless Ni-P coating with subsequent oxidization is a well-established technique for ultra-high absorptance black finish [1–4], although the darkest man-made surfaces are made of carbon nanotubes (CNTs) [5]. The robust surface of the black Ni-P coating is preferable for minimising the risk of accidentally damaging the dimensionally critical baffles of large size. On the contrary the CNT forest is quite fragile. The black electroless nickel has outstanding mechanical properties and stability against sunlight exposure in humid as well as extreme space conditions.

Chromium is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. While chromium metal and Cr(III) ions are not considered toxic, hexavalent chromium, Cr(VI), is both toxic and carcinogenic. 85 % of the available chromium is used in metal alloys. The remainder is used in the chemical, refractory, and foundry industries. Chromium compounds are used in leather products, dyes, paints, cement, mortar and are anti-corrosives. Chromium salts (chromates) are allergic to some people. Chrome ulcers are often found in workers that have been exposed to strong chromate solutions in electroplating, tanning and chrome-producing manufacturers [1, 2]

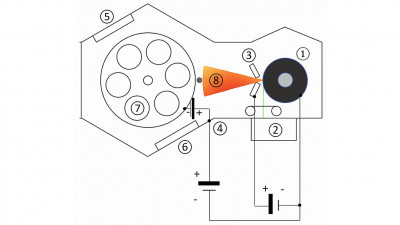

Anodic oxide coatings are formed on the metallic job by an electrochemical process known as anodizing. The process is carried out in an electrolytic cell where a job is made of an anode and a suitable inert metal as a cathode (Figure 3.1). When the electric current of sufficient voltage is passed through a suitable electrolyte the metal surface is converted to an adherent oxide coating which is an integral part of the substrate [1–4].

Chemical conversion coatings are one of the most common surface modification techniques that provide a barrier between metal and its surrounding environment [1]. The treatment can be carried out by dipping, spraying or by application of brush. The term chemical conversion is used where the exposed metal surface gets converted into the chemically inert inorganic coating by a chemical or electrochemical process. The coatings, in addition to corrosion protection, may impart requisite functional properties, enhanced surface hardness and a good base for application of subsequent paints, lubricants, adhesives, etc. The properties of these coatings depend on the kind of substrate metal, the composition and structure of the coatings. On the other hand, the composition and structure of the coatings depend on the bath composition and operating parameters of the process.

There is a growing demand for light metal alloys components in aerospace and automobile fields primarily to save fuel cost. Magnesium alloys promise a great potential for various applications as lightweight structural materials. This advantage stems from their low densities and high specific strength/weight ratio. Other advantages are good electrical and thermal conductivity, good impact strength, ability to dampen shockwaves, ease of forming at room temperature, weldability, buckling resistances, ductility and pressure tightness. Despite sounding like a designers' dream metal, magnesium has two grave drawbacks that limit their widespread applications. One is their poor corrosion resistance. These alloys are prone to oxidation even at room temperature when exposed to atmosphere. The other is their relatively frail surface mechanical properties, e.g. hardness, wear resistance, etc. Owing to the exceptional engineering properties of magnesium alloys ample attempts have been made in last few decades to develop the suitable surface protection techniques. In this article the advances of chemical conversion coatings on the magnesium alloys are discussed for ready reference of users.