First case study: the bionic development of the biological rust remover that Würth has in its catalog

In molecular bionics, a simplified abstract model helps to get to the heart of the question "Development of a natural rust remover" in order to form a picture of the usually complex reality that can be used to discuss it with experts:

Question 1: What does a rust pustule actually look like?

The hand-drawn sketch of a practitioner, quickly drawn for the bionics expert (Fig. 1), explains how a rust pustule is composed of very diverse multivalent iron compounds, mainly red and brown shimmering trivalent iron oxide hydroxides.

Question 2: What does a commercially available mineral acid-based rust remover do with the iron oxide hydroxides?

The chemistry book provides information: HCl, for example, reacts with Fe to form FeCl2 and solubilizes the iron-containing products into the solution.

Question 3: Where in nature does 'trivalent iron' play a role?

Every child knows the answer: iron is found in the blood - the red blood cells (haemoglobin) contain iron, they transport oxygen (andCO2) from the lungs, for example, to the brain and muscles, etc.

Question 4: How is 'iron' stored in humans, for example?

Since the oxygen supply (respiration) for the brain, for example, is vital for our survival (around 40 mL O2 per minute), there must be storage systems for iron in nature so that hemoglobin can be produced quickly in the event of blood loss.

An important iron storage molecule is ferritin, which can store several 1,000 iron atoms in a hollow sphere-like structure [14]).

Question 5: How, for example, is 'iron' transported from the 'iron storage molecule' in humans to the liver and spleen, the sites where hemoglobin is synthesized?

Logically, there must be transporters in nature that on the one hand take iron from the storage and bring it to where iron-containing proteins are assembled, but on the other hand also bring it from the environment into the body/cells.

When researching, you will quickly find what you are looking for in a basic textbook, e.g. in "Schlegel" [14], if you open the section "Transport of iron": it says: "Siderophores are natural complexing agents, of which over 200 are known with complexation constants between 1023 and1052 for trivalent iron. Siderophores are excreted iron-free by microorganisms and plants into the environment as a kind of space shuttle (i.e. complexing agent is excreted into the environment, complexes mainly the trivalent iron, is retrieved and discharged from the iron in the cell to be excreted into the environment again) in order to bind / complex iron(III) ions.

An iron-siderophore complex is formed, which is transported back into the organism via specific receptor and transport systems. The iron is released from the complex in various ways and then reduced to the usable iron(II) ion for the cell to make it available to the cell. A complex formation constant of1052 only means something to the expert: for the pragmatist it should be noted that this siderophore is able to dissolve iron from window glass.

Iron is an essential metal for cell growth and is required for various redox processes in metabolism. If a solution contains no iron, no microbial growth is possible in it. And for the trivalent iron, which is present in oxygen-supplied media at a neutral pH value with a solubility of 10-18 LP, siderophores have evolved in aerobic microorganisms. Without the siderophores, no aerobic biological wastewater treatment would work, there would be no growth of the microorganisms important for the treatment (the formation of sewage sludge therefore shows that the wastewater treatment organisms must have siderophores).

Once we have found a functional analogy of an "iron transporter" in humans, medicine automatically comes into play:

Question 6: Are there medical products in which siderophores are used?

When iron is "needed", the store is emptied: the doctor determines the ferritin value and prescribes iron-containing preparations or foods that contain a lot of iron (black pudding, red meat, etc.). Acute iron poisoning is rare; chronic poisoning, usually due to an inherited genetic defect, is diagnosed as hemochromatosis or siderosis and treated with, for example, a preparation containing siderophore (desferrioxamine), which Professor Hans Zähner at the University of Tübingen initially researched and fermented as an antibiotic. Today, it is often used as a suffix before dialysis (kidney flushing) to prevent iron precipitation in front of the dialysis membrane.

Even though it was very expensive, a molecule was thus found that could be used to biologically remove rust film pustules from metal surfaces.

Question 7: Can siderophores be used commercially as rust removers?

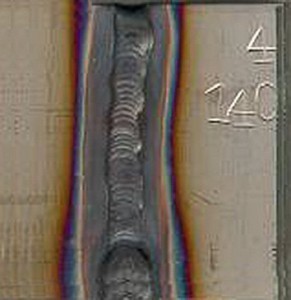

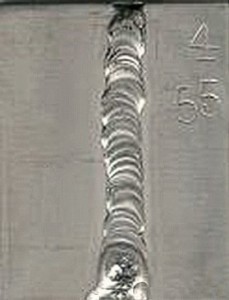

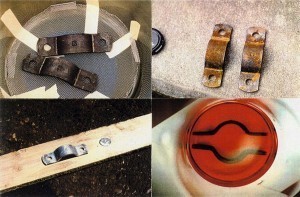

Fig. 2: Rusted clamps (top right) - biological rust removal bath (below) - dry blow-dried clamps after 20 minutes (top left) - hot-dip galvanized clamp (below)Since 1992, more than two dozen biologists, mineralogists, biotechnology, chemical and process engineers at the Institute of Biological Process Engineering at Mannheim University of Applied Sciences have been working on the fundamentals and their implementation, starting with the rust removal of steel surfaces (Fig. 2) to the removal of tarnish from high-alloy steels (Fig. 3). In the latter case, the exciting task was how to remove the chromium-depleted zone biologically or with natural products. It started with one gram of desferrioxamine B, donated by Ciba-Geigy, Basel(Fig. 2 shows rust removal tests on clamps that were later hot-dip galvanized), and with a few kilograms of desferrioxamine B, donated by Novartis, Basel, the systematic tests were continued and a formulation was found that also removes tarnish.

Fig. 2: Rusted clamps (top right) - biological rust removal bath (below) - dry blow-dried clamps after 20 minutes (top left) - hot-dip galvanized clamp (below)Since 1992, more than two dozen biologists, mineralogists, biotechnology, chemical and process engineers at the Institute of Biological Process Engineering at Mannheim University of Applied Sciences have been working on the fundamentals and their implementation, starting with the rust removal of steel surfaces (Fig. 2) to the removal of tarnish from high-alloy steels (Fig. 3). In the latter case, the exciting task was how to remove the chromium-depleted zone biologically or with natural products. It started with one gram of desferrioxamine B, donated by Ciba-Geigy, Basel(Fig. 2 shows rust removal tests on clamps that were later hot-dip galvanized), and with a few kilograms of desferrioxamine B, donated by Novartis, Basel, the systematic tests were continued and a formulation was found that also removes tarnish.

Question 8: Can siderophores other than those used in medicine be fermented?

Dr. Arno Cordes, Managing Director of ASA-Spezialenzyme Wolfenbüttel, and his colleagues have been researching this topic since 2000 and have established a fermented siderophore desferrioxamine E as an alternative to the medical product.

Question 9: How do you turn it into a product?

Today, ASA-Spezialenzyme offers liquid-based biological rust removal products for immersion bath applications that are (still) affordable and supplies Würth, Künzelsau, with a paste that can be brushed onto rusty areas, where the product is simply called "Rost-Ex-Gel".

The rust removal products are adjusted to the pH value of 5.5 known from the skin, are biodegradable (and can promote iron metabolism in biological waste water plants) or can be used as a plant substrate for plants suffering from iron deficiency diseases.

Second bionic case study: iron removal from rinsing baths after iron pickling without precipitation

The author has actually been involved in metal biology since the early 1980s, originally focusing on the microbiocidal effect of copper, silver and other heavy metals (see [10]). One day, the plant manager of a hot-dip galvanizing plant in Maintal asked whether it was biologically possible to remove iron from rinsing baths without precipitants to such an extent that the carry-over into subsequent process steps would be low and their service life (especially during fluxing) would be "infinite, at least very long".

As described above, the task was jointly focused on the core question: In which charge states is iron present in the rinsing bath (especially after a new batch of the rinsing bath)? A model was then created to describe how iron ions from stripped rust particles accumulate ionically depending on the pH value.

Basic information on iron

Together with manganese, iron is the most common heavy metal in the earth's crust. After weathering of iron-containing primary minerals, iron is released under oxidizing conditions as a trivalent or tetravalent oxide, hydroxide or oxide hydrate of different colors (yellow-brown, blood-red, orange, red-brown). The compounds are all poorly soluble in water, so that reductive processes (chemical-physical or biological) are required to convert them as divalent compounds into a water-soluble form (oxides, hydrogen carbonates, carbonates). The equilibrium of the reaction is influenced on the one hand by the solubility of the metal oxides (solubility product) and on the other hand by the redox potential or pH value. For example, the solubility of iron hydroxide Fe(OH)3 is 4.8 - 10-5 mg/l. While iron is increasingly chemically released and mobilized at a redox potential Eh < 300 mV and a pH value < 4, the metal is oxidized and fixed as the pH value increases [4]. Iron occurs in aqueous solution under natural conditions in two oxidation states: As Fe(II), it is a strong reducing agent in alkaline solution, which in turn is oxidized to Fe(III). Conversely, the Fe(III) ion behaves as an oxidizing agent under acidic conditions. This means that Fe(III) is the more stable ion under alkaline conditions and Fe(II) under acidic conditions [5]. Rust is often described as hydrated iron(III) oxide (FeO(OH) = ½ Fe2O3×H2O). More precisely, rust is a mixture of different proportions of iron(II) oxide (FeO, wüstite), iron(II/III) oxide (Fe3O4 magnetite), iron(III) oxide (Fe2O3, hematite) and iron(III) hydroxide oxide (FeO(OH)) (according to [1]).

Bionic continues ...

Then began the search for analogies and where and how "nature" interacts with iron, which is essential for growth. It was clear from the outset that precipitation reactions with microbially produced phosphoric acid, for example, could not be considered. It was also clear that it had to be biomass that could be easily removed from the system. Since the Cher Nobyl reactor disaster (April 26, 1986) was still relatively recent, and since we in Germany were still not supposed to pick and eat forest mushrooms in German forests a good two years later due to uranium enrichment, the "initial suspicion" fell on "mushrooms", both on mushroom mycelia (mostly underground "threads") and on the plektenchyma (visible fruit nodes that can be bought in grocery stores).

The basics of biosorption

Of course, a researcher does not start researching straight away, but instead looks at the basic principles available at the time (around the turn of the millennium), of which only a brief excerpt is given here (the complete version can be found in [8]). It should also be borne in mind that the metal "iron" was not the focus of the research groups, as the phytoremediation of uranium, for example, was more environmentally relevant.

![Abb. 4: Pelletbildung bei Aspergillus niger in Schüttelkolben mit Schikanen (die Pellets weisen variierende Durchmesser und eine „stachelige“ Oberflächenstruktur auf; im Schüttler mit 100 rpm, 24 °C) [8] Abb. 4: Pelletbildung bei Aspergillus niger in Schüttelkolben mit Schikanen (die Pellets weisen variierende Durchmesser und eine „stachelige“ Oberflächenstruktur auf; im Schüttler mit 100 rpm, 24 °C) [8]](/images/stories/Abo-2021-10/thumbnails/thumb_gt-2021-10-0122.jpg) Fig. 4: Pellet formation in Aspergillus niger in shake flasks with baffles (the pellets have varying diameters and a "spiky" surface structure; in the shaker at 100 rpm, 24 °C) [8]

Fig. 4: Pellet formation in Aspergillus niger in shake flasks with baffles (the pellets have varying diameters and a "spiky" surface structure; in the shaker at 100 rpm, 24 °C) [8]

The mechanisms of uptake and accumulation of metals by fungi (and yeasts) and plants are referred to as biosorption (adsorption plus chemisorption). In addition to the uptake of iron (and manganese for photosynthesis in plants), there are also mechanisms of encapsulation (e.g. of mercury) and even metal uptake in order to poison predators that want to feed on the plant.

![Abb. 5: Sorptionsisotherme mit Streptomyces cinnamoneum für Spülbad in einer Feuerverzinkerei im Schüttler (Rührgeschwindigkeit 100 rpm, Temperatur 20 °C; Untersuchungszeit 40 h) [8] Abb. 5: Sorptionsisotherme mit Streptomyces cinnamoneum für Spülbad in einer Feuerverzinkerei im Schüttler (Rührgeschwindigkeit 100 rpm, Temperatur 20 °C; Untersuchungszeit 40 h) [8]](/images/stories/Abo-2021-10/thumbnails/thumb_gt-2021-10-0111.jpg) Fig. 5: Sorption isotherm with Streptomyces cinnamoneum for rinsing bath in a hot-dip galvanizing plant in a shaker (stirring speed 100 rpm, temperature 20 °C; test time 40 h) [8]

Fig. 5: Sorption isotherm with Streptomyces cinnamoneum for rinsing bath in a hot-dip galvanizing plant in a shaker (stirring speed 100 rpm, temperature 20 °C; test time 40 h) [8]

During biosorption, metals accumulate on the cell surface through precipitation and binding reactions. The sorption of metals by microorganism or plant cells is essentially a passive process that requires no metabolic energy and is primarily controlled by physico-chemical factors. It therefore occurs in living and dead cells as well as in cell debris. A number of processes have been identified to explain sorption at cell surfaces, including cation exchange, complex formation or coordination, chelation and microprecipitation.

![Abb. 6: Sorptionskinetik von Agaricus bisporus: verwendet wurden unbehandelte Champignonköpfe, die in ihrer Masse 1 g Biotrockenmasse entsprachen [8] Abb. 6: Sorptionskinetik von Agaricus bisporus: verwendet wurden unbehandelte Champignonköpfe, die in ihrer Masse 1 g Biotrockenmasse entsprachen [8]](/images/stories/Abo-2021-10/thumbnails/thumb_gt-2021-10-0112.jpg) Fig. 6: Sorption kinetics of Agaricus bisporus: untreated mushroom heads with a mass equivalent to 1 g dry biological mass were used [8]

Fig. 6: Sorption kinetics of Agaricus bisporus: untreated mushroom heads with a mass equivalent to 1 g dry biological mass were used [8]

The level of sorption capacity of individual organism species is based on differences in the structure of their cell walls [11]. In the case of bacteria (cell walls with the mucopolysaccharide peptidoglycan as the main component), the cell wall is primarily anionic to the environment, which is due to the presence of functional groups such as carboxyl, hydroxyl, sulphyl and phosphyl. The different types of polar groups present and the charge distribution within the cell wall explain the differences in metal sorption between the individual species and strains. Among the functional groups in algal cell walls are carboxyl, amyl, hydroxyl, phosphyl, amide, inidazole, thio and thioether units. Some algae genera, including Chlorella and Ulothrix, are said to have considerable metal absorption capacity [3].

![Abb. 7: Eisenbeladungen von Streptomyces cinnamoneum in Abhängigkeit von pH-Werten des voreingestellten Spülbades [8] Abb. 7: Eisenbeladungen von Streptomyces cinnamoneum in Abhängigkeit von pH-Werten des voreingestellten Spülbades [8]](/images/stories/Abo-2021-10/thumbnails/thumb_gt-2021-10-0113.jpg) Fig. 7: Iron loadings of Streptomyces cinnamoneum as a function of pH values of the preset rinsing bath [8]

Fig. 7: Iron loadings of Streptomyces cinnamoneum as a function of pH values of the preset rinsing bath [8]

Using Penicillium chrysogenum, Volesky et al [24] achieved a lead removal of 116 mg per g dry mass at a pH value between 4-5. The following "affinity series" for metals was established: Pb2+ > Cd2+ > Cu2+ > Zn2+. Ordinary baker's yeast has also been shown to exhibit metal uptake rates of 0.058 mmol/g for uranium and 0.56 mmol/g for zinc in the pH range between 4 and 5, with the uptake rates for dead Saccharomyces cerevisiae being about 40 % higher. Biosorption is described as a rapid process in which 60 % of the maximum sorption rate is reached after only 15 min [23]. The binding "active sites" for zinc ions in non-living baker's yeast are the phosphoryl and carboxyl groups of the cell wall. He attributed the physico-chemical phenomenon of biosorption to adsorption, ion exchange, complexation and microprecipitation, caused by a dissociation of the carboxylate groups of the biomass in the pH range of 4-5, which leads to negatively charged surfaces. This leads to electrostatic interactions between the cell surface and cations, whereby not only the charge of the ion but also its ionic radius plays a role.

Formulation of a requirement profile for the bionic solution

In order for iron biosorption to compete with conventional processes in terms of efficiency and cost-effectiveness, the following criteria must be met:

![Abb. 8: Champignons (Agaricus bisporus) in der Glassäule, deutlich ist auf den Oberflächen ein grüner Niederschlag zu erkennen werden [8] Abb. 8: Champignons (Agaricus bisporus) in der Glassäule, deutlich ist auf den Oberflächen ein grüner Niederschlag zu erkennen werden [8]](/images/stories/Abo-2021-10/thumbnails/thumb_gt-2021-10-0115.jpg) Fig. 8: Mushrooms (Agaricus bisporus) in the glass column, a green precipitate can be clearly seen on the surfaces [8]

Fig. 8: Mushrooms (Agaricus bisporus) in the glass column, a green precipitate can be clearly seen on the surfaces [8]

1. the biomass should be inexpensive to obtain (preferably free of charge). The following were suitable:

- Saccharomyces cerevisiae (brewer's yeast from breweries)

- Penicillium chrysogenum (dead autoclaved as waste from penicillin production)

- Streptomyces strains (dead autoclaved as waste from antibiotic production).

2. high and fast iron accumulation capacity of the biosorbent: a sorption capacity of > 150 mg/g dry matter was considered good (because then the iron-biomass agglomerate can be used as a reducing agent in the steel industry and iron can be utilized in the smelting process).

3. ideally, the biosorption capacity should not be influenced by other bath components and should be relatively stable against pH changes. This is the highest requirement in the development of biosorption systems.

4. selectivity: If the process focuses on the targeted recovery of a metal, the sorption process should be selective. In the case of Aspergillus niger, for example, Yakubu, Dudeney [25] reported Fe3+>Cu2+>Zn2+.

Biological detail work: screening of different biomasses for their ability to accumulate iron

In a screening, 16 different biomasses were examined for their ability to remove iron from rinsing baths. Biomasses that were not available in sufficient quantities were cultivated and enriched in surface and/or submerged processes; for example, Aspergillus niger, which produces 100 thousand tons of citric acid annually.

The sorption rates of autoclaved (dead) biomass were significantly higher than those of living biomass in the majority of the tests (see above). The biomasses examined showed sorption rates of between 13 and 157 mg/g BTM (bio-dry mass) at pH 4.0, whereby the autoclaved and dried cells of Streptomyces cinnamoneum with over 150 mg/g BTM were far above the loadings of other cells. In the work by Purnik and Puknikar [13], only 57.7 mg/g for lead and 21.3 mg/g for zinc were specified for this strain.

![Abb. 9: Erfolg des Verfahrens: Werden ein beizsaures Eisenspülbad (ganz links) und Abfallbiomasse aus Fermentationen in Kontakt gebracht (2. von links), kann aufgrund von Biosorption ein Eisenschlamm (2. von rechts) und eine leicht-saure bis neutrale, eisenfreie Lösung erzeugt werden [8] Abb. 9: Erfolg des Verfahrens: Werden ein beizsaures Eisenspülbad (ganz links) und Abfallbiomasse aus Fermentationen in Kontakt gebracht (2. von links), kann aufgrund von Biosorption ein Eisenschlamm (2. von rechts) und eine leicht-saure bis neutrale, eisenfreie Lösung erzeugt werden [8]](/images/stories/Abo-2021-10/thumbnails/thumb_gt-2021-10-0117.jpg) Fig. 9: Success of the process: If an acidic iron rinsing bath (far left) and waste biomass from fermentations are brought into contact (2nd from left), an iron sludge (2nd from right) and a slightly acidic to neutral, iron-free solution can be produced due to biosorption [8]

Fig. 9: Success of the process: If an acidic iron rinsing bath (far left) and waste biomass from fermentations are brought into contact (2nd from left), an iron sludge (2nd from right) and a slightly acidic to neutral, iron-free solution can be produced due to biosorption [8]

The biosorption results of commercially available mushrooms (Agaricus bisporus) showed 50 mg/g and 80 mg/g BTM in the column test in a shake flask.

In a model experiment, it was shown that 100% purification of the rinsing bath from iron is possible with a pre-dilution of 1:20 with Streptomyces cinnamoneum. The product was a clear liquid with a zinc content of only 0.2 g/l, in which no more iron was detectable.

The investigations were then continued under real conditions in a hot-dip galvanizing plant in Neunkirchen. The plant was tested under extreme conditions (pH below 0, iron content 55 g/l, temperatures only just above freezing point). In addition, the process was confronted with a zinc content of 54 g/l. It turned out that in continuous operation with a waste mycelium from penicillin production, average loadings of both iron and zinc of 130 mg/g BTM each (i.e. a total of 260 mg metal per g BTM) can be achieved.

As the results showed, it is practically possible to clean metal-containing rinses from the metal processing industry by biosorption on the cell surface of microorganisms. Suitable biomasses were found that are characterized by a very high iron-binding capacity.

5 Doing bionics

Young people in particular should take an interest in bionic approaches after graduation, especially if they have not been exposed to bionics in their university studies.

By the end of his studies at the Technical University of Karlsruhe, now KIT-Süd, the author had realized that his fellow students (civil engineers) had nothing to do with biology and his fellow biology students had nothing to do with technology, which is why he was able to occupy this niche quite successfully.

Even today, young people are advised to focus on bionics and to see an aspect for their personal professional future in the fact that they can show their companies new ways of developing sustainable products and processes inspired by nature.

Literature

[1] Christen, H.R.: Grundlagen der allgemeinen und anorganischen Chemie, Verlag Sauerländer, Aarau, Diesterweg, Salle, Frankfurt am Main, 1973

[2] Gorb, S.N.; Voigt, D.: Functional biological surfaces as models for technology, Performance Doppelausgabe, 2009, 68-77

[3] Hardmann, D.J.: Pollution: Ecology and Biotreatment, Longman Group UK Limited, 1993

[4] Hollemann, A.F.; Wieberg, E.: Lehrbuch der anorganischen Chemie, 56th edition, Walter de Gryter & Co, Berlin, 1960

[5] Kolditz, L. [Ed:] Anorganikum, 13th newly revised edition, Johann Ambrosius Barth, Leipzig, Berlin, Heidelberg, 1993

[6] Kunz, P.M.: 4th Bionics Congress Baden-Württemberg - learning from nature, John Deere Forum, Mannheim, 2019

[7] Kunz, P.M.; Sommer, I: Bionic developments in surface technology, Jahrbuch Oberflächentechnik Volume 70, Eugen G. Leuze Verlag, Bad Saulgau, 2014

[8] Kunz, P.M.; Monzel, M.: Biosorptive removal of iron compounds from rinsing baths in the metal industry, Project Final Report Innovative Project of the State of Baden-Württemberg, Mannheim University of Applied Sciences, 2002

[9] Kunz, P.M.: Umwelt-Bio-Verfahrenstechnik, Vieweg Verlag, Wiesbaden, 1992

[10] Kunz, P.M.; Frietsch, G.: Mikrobizide Stoffe in biologischen Kläranlagen - Immissionen und Prozessstabilität, Springer Verlag, Berlin, 1986

[11] McEldowney, S.: Microbial biosorption of radionuclides in liquid effluent treatment, Appl. Biochem. Biotechnol.; 26, 1990, 159-180

[12] Nachtigall, W.; Wisser, A.: Bionics in examples: 250 illustrated approaches, Springer Spektrum Verlag, 2013

[13] Puranik, P.R.; Paknikar, K.M.: Biosorption of lead and zinc from solutions using Streptoverticillium cinnamoneum waste biomass, Journal of Biotechnology 55, 1997, 113-124

[14] Schlegel, H.G.: General Microbiology, Thieme Verlag, 1985

[15] VDI 2221: Methodology for the development and design of technical systems and products, Verein Deutscher Ingenieure, Beuth-Verlag, May 1993

[16] VDI 2221 Sheet 1: Development of technical products and systems - Model of product development, Verein Deutscher Ingenieure, Beuth-Verlag, March 2018

[17] VDI 2221 Sheet 2: Development of technical products and systems - Design of individual product development processes, draft, Verein Deutscher Ingenieure, Beuth-Verlag, March 2018

[18] VDI Status Report: Life Sciences - Trends and Perspectives, [1] VDI Status Report Association of German Engineers, October 2018

[19] VDI 6220: Bionics - Concept and strategy, differentiation between bionic and conventional processes/products, Verein Deutscher Ingenieure, Beuth-Verlag, December 2012, 2013

[20] VDI 6220 Sheet 1: Bionics - Fundamentals, conception and strategy, Verein Deutscher Ingenieure, Beuth-Verlag, Gründruck 2019

[21] VDI 6221: Bionics - Bionic surfaces, Association of German Engineers, Beuth-Verlag, September 2013

[22] VDI 6223: Bionics - Bionic materials, structures and components, Verein Deutscher Ingenieure, Beuth-Verlag, June 2013

[23] Volesky, B.; May Phillips H.A.: Biosorption of heavy metals by Saccharomyces cerevisiae, J. Appl. Microbiol Biotechnol. 42, 5, 1995, 797-806

[24] Volesky, B.; Niu, H.; Xu, X.S.; Wang, J.H.: Removal of lead from aqueous solutions by Penicillium biomass, Biotechnol. Bioeng. 42, 1993, 785-787

[25] Yakubu, N.A.; Dudeney, A.W.L.: Immobilization of Ions by Biosorption, Hydrometallurgy, 1986

[26] Zhao, H.; Sun, Q.; Deng, X.; Cui, J.: Earthworm-Inspired Rough Polymer Coatigs with Self-Replenishing Lubrication for Adaptive Friction-Reduction and Antifouling Surfaces, Advanced Materials 30, 29, 2018, 1802141

[27] http://www.biokon.de/bionik/was-ist-bionik/