kortec Industrielektronik GmbH, Sinsheim, has expanded its design capabilities to include mechanics. The EMS service provider can now not only offer its customers test and programming adapters, as well as soldering and assembly devices, but can also develop and manufacture housing prototypes specifically according to customer requirements. Thanks to the corresponding software, a modern FLM 3D printer and a 3-axis CNC milling machine, kortec is able to react quickly to mechanical customer requests.

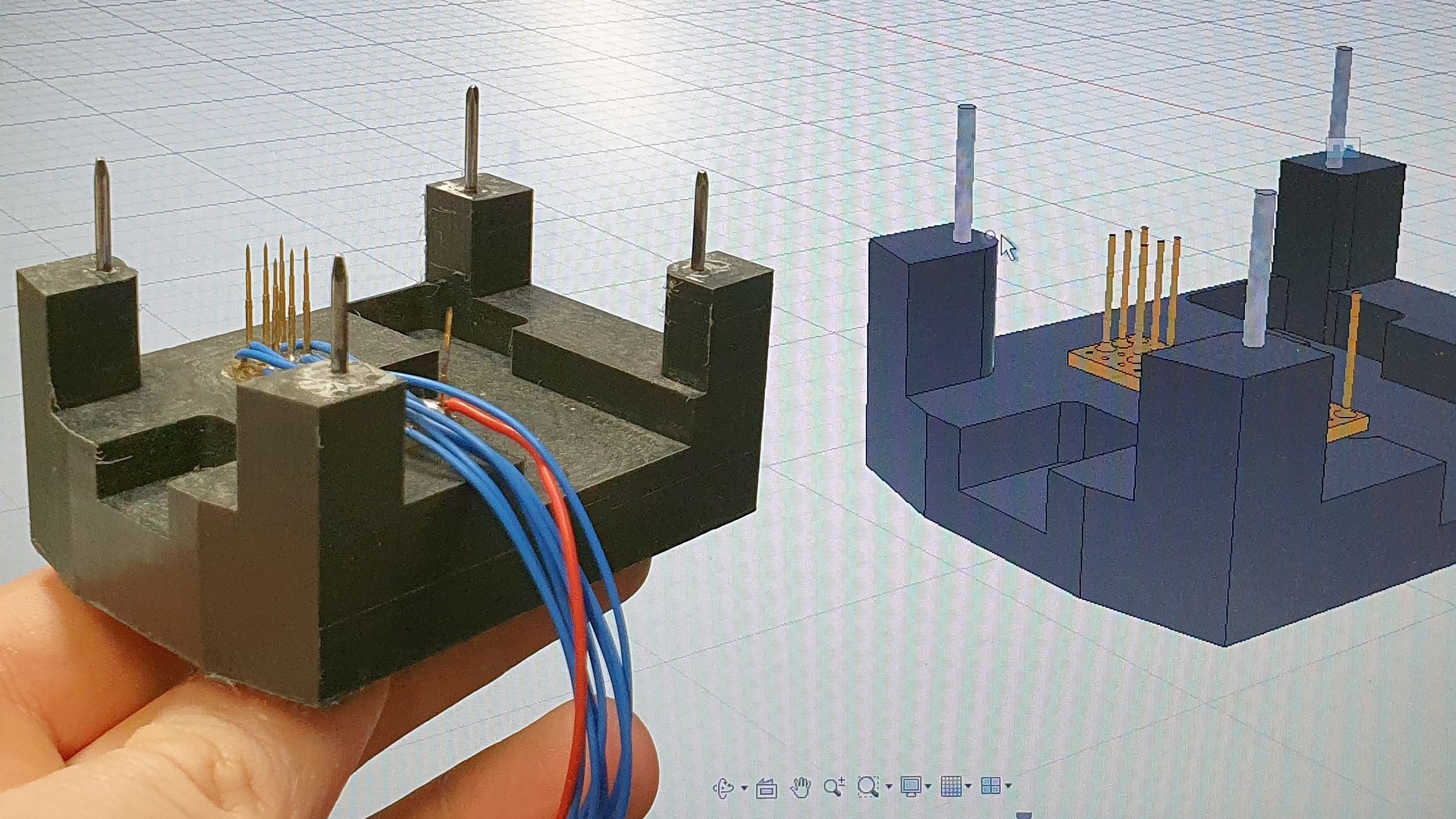

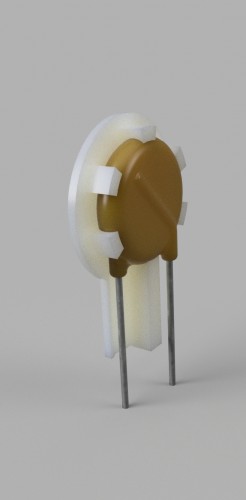

The investment enables kortec to produce prototypes of housings, devices for assembly or soldering work, as well as spare parts at short notice. For example, a customer-specific programming adapter has recently been designed and manufactured on this basis, which significantly reduces the programming time for the special assembly. Another example is a soldering device for a varistor, with the help of which a distance of 10 mm to the circuit board required by the customer is guaranteed.

Prototypes and small series: Housing solution from the 3D printer

Prototypes and small series: Housing solution from the 3D printer