Covestro, one of the world's leading manufacturers of high-quality plastics, whose key customers include the electrical and electronics industry, has presented a comprehensive plan to achieve climate neutrality by 2035. The company's vision is based entirely on a circular economy. In the long term, this should encompass the entire production and product range of the materials manufacturer as well as all areas of the company. One concrete measure towards this goal is climate neutrality.

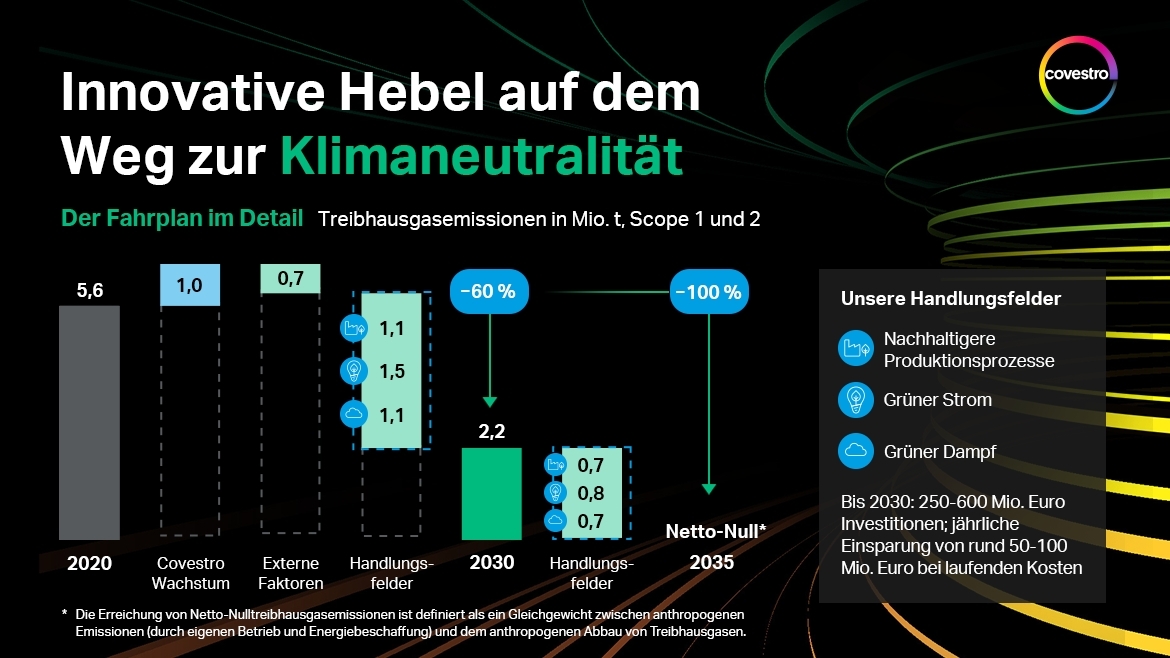

Covestro was already able to reduce its greenhouse gas emissions by 54% in 2021 compared to 2005, thus already exceeding the 2025 sustainability target set at the time. The newly set ambitious target of becoming climate neutral by 2035 is specifically divided into greenhouse gas emissions from our own production (Scope 1) and external energy sources (Scope 2): These are to be reduced by 60% to 2.2 million tons by 2030. Indirect greenhouse gas emissions from upstream and downstream processes in the value chain (Scope 3) are also to be further reduced. A reduction target for this is to be announced by 2023. In order to achieve net zero emissions, the company estimates that it will need to invest between € 250 million and € 600 million by 2030. Increasing energy efficiency is expected to lead to annual operating cost savings of between € 50 million and € 100 million. On the way to net-zero emissions, Covestro also expects higher operating costs in the low three-digit million euro range per year - these assumptions are based on the historical experience that prices for fossil fuels are lower than those for renewable energies.

Three levers contribute significantly to achieving the climate targets:

- Production processes will be further improved and energy efficiency promoted in order to achieve even more sustainable production processes. One focus is on reducing nitrous oxide emissions through the increased use of highly efficient, innovative catalytic converters. Thanks to the further digitalization of operations and the use of digital technologies, production facilities can also be controlled more efficiently and processes can be optimized through digital simulations. Digital technologies also help to collect and track emissions data along the entire value chain.

- Covestro's production sites worldwide are gradually being converted to green electricity. This includes the use of offshore wind energy, including through a supply agreement with the energy provider Ørsted, which will cover 10% of the energy required at the company's German sites from 2025. Onshore wind energy is also to be used, for example as part of the power purchase agreement with ENGIE, which covers 45% of the energy requirements of Covestro's site in Antwerp (Belgium). Around 10% of Covestro's energy requirements in Shanghai (China) already come from the solar parks of Datan Wuzhong New Energy Co. In addition to the existing cooperation models with electricity providers, further agreements are planned to achieve a net-zero carbon footprint.

- Steam is an important source of energy in chemical production processes. Covestro wants to solve the challenge of converting steam generation from fossil fuels to renewable energies by several means. To this end, the company is investigating the use of biogas and green natural gas as energy sources to generate green steam. Green hydrogen and green ammonia or green electricity could also be used as energy sources for steam generation.

At the start of the 2022 fiscal year, Covestro will update and expand its existing management system and add a sustainability component, measured in 2022 in terms of direct and indirect greenhouse gas emissions (Scope 1 and 2). In the future, Covestro will offer every product in a climate-neutral version. A pioneering example of sustainable products is the world's first climate-neutral polycarbonate, manufactured using raw materials from mass-balanced biowaste and residual materials as well as renewable energy. It has been supplied to customers since 2021.