The Bodo Möller Chemie Group is expanding its cooperation with the manufacturer Henkel Bergquist and offers the complete product family of thermally conductive materials for applications in electronics and electrics for the DACH and Benelux regions. "Henkel offers comprehensive solutions in the market to solve thermal challenges in bonding and insulation in electrical applications. Demand is growing enormously, especially in the automotive and aerospace sectors, but also in many other industries. Henkel Bergquist is therefore the ideal partner to offer users a complete portfolio of solutions from a single source," says Frank Haug, CEO of Bodo Möller. The specialty chemicals company's own plotter service also enables it to supply customers with ready-to-use products such as Thermal GAP PAD®, Thermal SIL PAD®, High Flow (phase change materials) and Bond Ply, a double-sided adhesive solution for thermally stressed bonds. In addition to ready-plotted products, all liquid materials such as thermal gap fillers are also available.

Cutting Competence Center: Delivery "on demand"

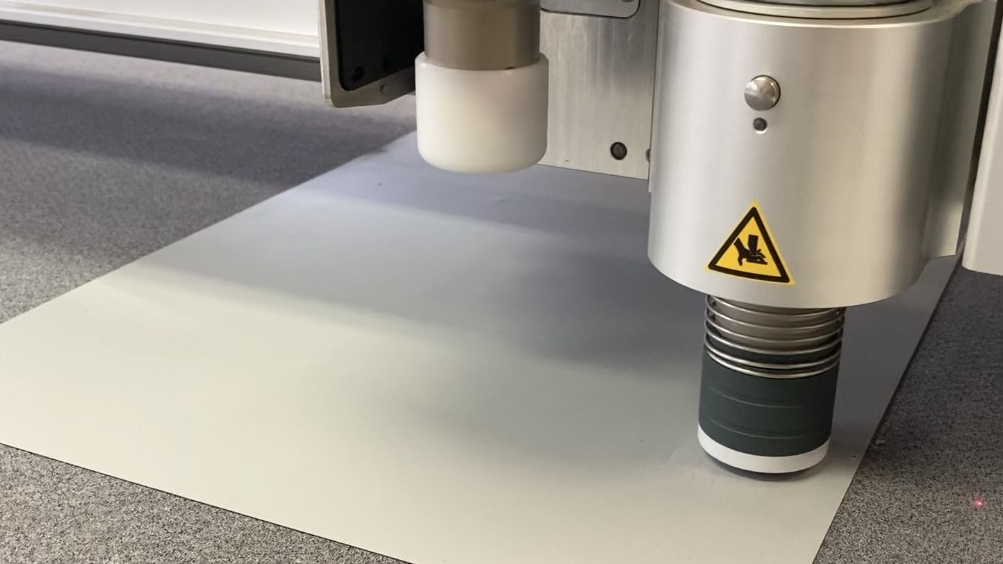

With its own plotter and the newly founded "Cutting Competence Center", the Bodo Möller Chemie Group is going one step further: "We see a growing need among customers to not only receive products and expertise from a supplier like us, but also pre-produced products that can be processed directly. We guarantee the expertise and therefore the consistent quality of the products we plot," explains Berit Hoffmann, Account Manager at Bodo Möller. Effective cooling extends the service life and reliability of electronic components; LED lamps, for example, retain their light color as they can be operated at a constant temperature. "Heat conduction is more than just the thermal conductivity value lambda. With our advice, we support the customer in selecting the optimum TIM for the application, while we can use the plotter to deliver the parts for series production or sampling at short notice," adds Berit Hoffmann from Bodo Möller Chemie.

From selection to the product

Thermal interface materials are increasingly being used in electronics - in battery packs, electric drives, modern automotive lighting solutions and power electronics - and are required by manufacturers and suppliers alike. Bodo Möller Chemie's own Cutting Competence Center is technically superior and can cut the thermally conductive material both with and without the underlying protective film according to the customer's drawing in a single operation, after which the components are inspected and optically measured using a state-of-the-art measuring microscope. Almost all contours are possible and production can be mapped from prototypes to large series. Thanks to digital cutting, contour adjustments can be made flexibly. This enables the Bodo Möller Chemie Group to map the entire value chain for thermally conductive solutions - from the selection of the most technically suitable material, including for the production and logistics chain, to cutting. Cutting and printing can be carried out in a single work step. "With this service, we are expanding our service portfolio together with Henkel Bergquist by a significant unit," summarizes Frank Haug, CEO of the Bodo Möller Chemie Group.