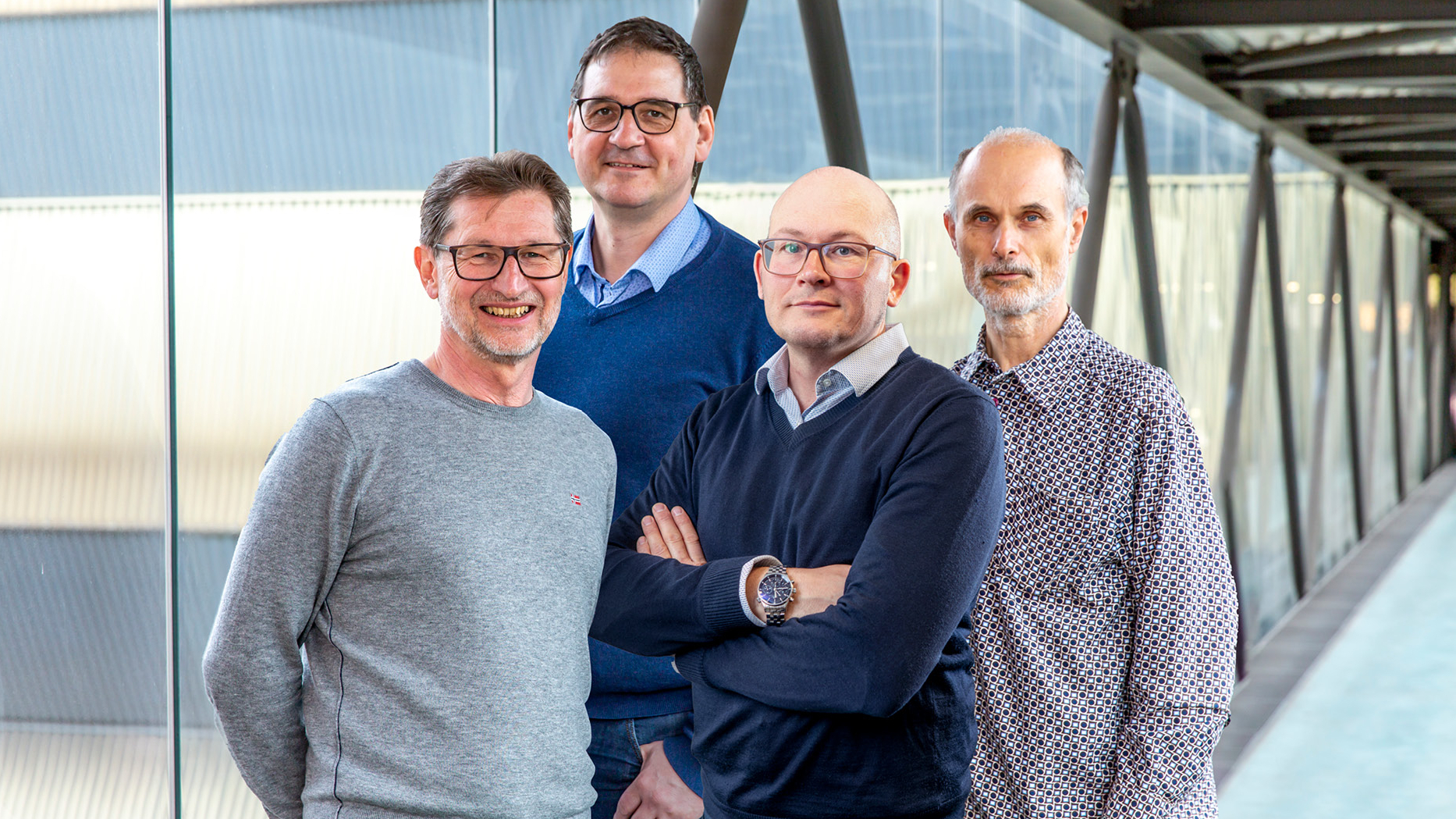

The four inventors of a pioneering steel coating Josef Faderl, Siegfried Kolnberger, Thomas Kurz and Andreas Sommer have reached the final of the European Inventor Award 2023. The prize was awarded on July 4 in Valencia, Spain, and was established by the European Patent Office in 2006.

The four inventors have developed a method to produce lighter galvanized steel parts for cars that are up to six times stronger than those made from conventional galvanized steel. For this purpose, an aluminium oxide layer is formed on the surface of the zinc coating as part of the so-called phs-ultraform process, which enables the galvanized steel to withstand the press hardening forming process, which takes place at 900 °C. The process first went into series production in 2008 and is now widely used in the automotive industry, where it ensures corrosion resistance and maximum strength even with challenging geometries. As a result, thinner steel sheets can be used and effective lightweight construction can be achieved, which ultimately also reduces emissions. Today, sheet metal processed in this way is used in five million cars every year.

In Valencia, the developers, who work at the Austrian steel manufacturer voestalpine, came away empty-handed - the winners were the Finns Pia Bergström, Annika Malm, Jukka Myllyoja, Jukka-Pekka Pasanen and Blanka Toukoniitty with an invention that turns waste into renewable fuels - but their finalist role showed the value of their invention for the steel and metal forming industry and the functionalization of surfaces and substrates.