Determining the oil content in the refrigerant circuit often presents users with challenges. Samples are difficult to take due to the high pressure in the circuit. In addition, the refrigerant volatilizes as soon as it is removed from the circuit. In some cases, the fact that flammable gases, such as propane (R290), are used as refrigerants makes things even more difficult. This naturally places special demands on the measuring systems. A special degree of protection is therefore required, particularly in large-volume test benches, which are often located in research and development centers.

Unbeatably simple and very precise

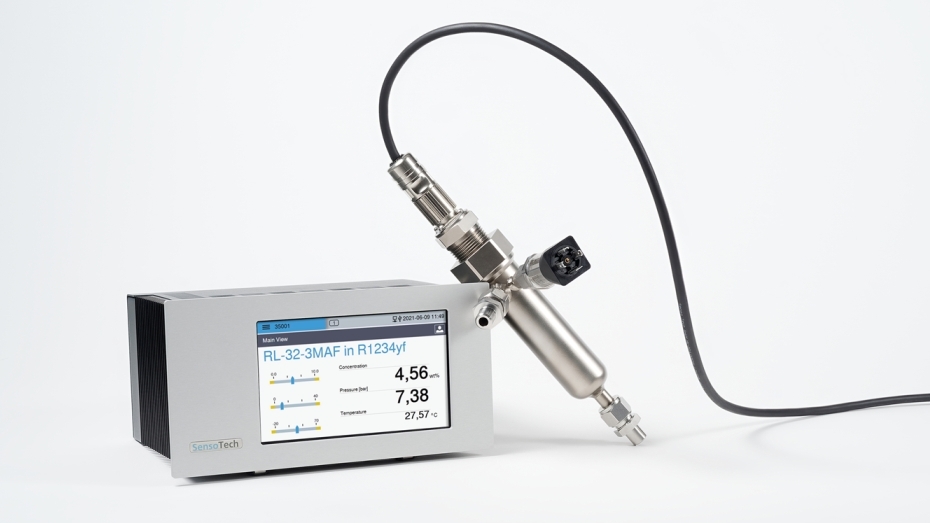

SensoTech has the solution for these cases: LiquiSonic® OCR determines the concentration of the oil directly in the refrigerant circuit without sampling and in real time - even in potentially explosive atmospheres. This means that users who previously had to resort to other measuring methods due to the increased hazard level can also use the measuring system. The sensor design is Ex-certified (ATEX, IECEx) and complies with industrial standards. The pressure sensor integrated in the system also complies with these regulations (ATEX, IECEx).

LiquiSonic® OCR has been impressing customers for years with its maintenance-free operation and very precise measurement results. When monitoring oil in refrigerants, the system achieves an accuracy of ±0.1 m%, depending on the oil and refrigerant used. Once installed, it provides permanent real-time measurement values and requires no maintenance.

SensoTech has already measured a large number of oil/refrigerant combinations for customers on the test stand in its in-house laboratory. For example, mixtures with oils such as ND11 and DAO 190 (CPS). Other combinations can be measured in the SensoTech laboratory at any time.

Simple, fast and maintenance-free

The complete measuring system comes with a process adapter, is plug&play and ready for use immediately after installation. The controller reliably displays the concentration, the prevailing pressure and the temperature of the process liquid. It offers the option of storing additional product data sets (calculation models), which allows a quick response to changing refrigerants or oils. Of course, the measured values can be saved and transferred for further analysis. Thanks to the robust sensor design, LiquiSonic® does not require any maintenance work.