Umicore's Metal Deposition Solutions (MDS) business unit has developed a new environmentally friendly platinum coating process for titanium components in PEM electrolyzers. This technology significantly improves occupational safety during the wet-chemical coating of components, as it does not require any highly corrosive or toxic chemicals.

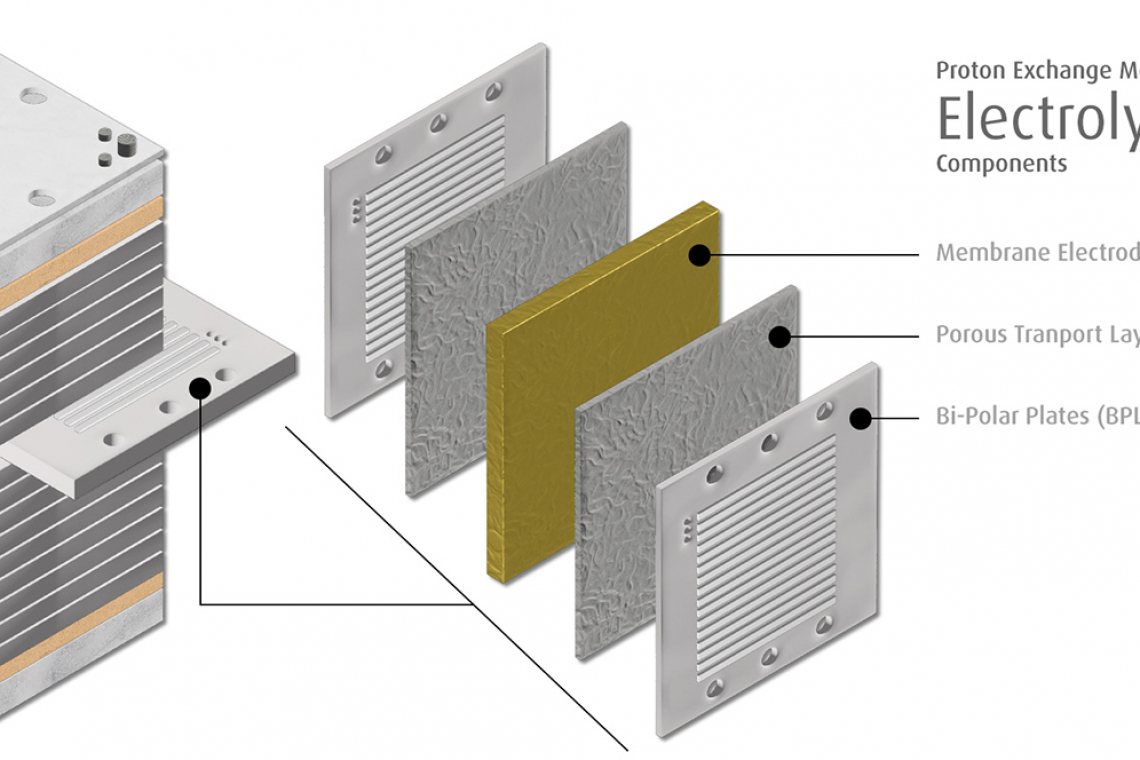

Umicore has set up production facilities worldwide for this particularly precise and therefore economical coating process in order to be able to coat components in close proximity to the customer at all times. Titanium is used as the base material for the components in order to withstand the demanding conditions of proton exchange membrane (PEM) electrolysis. In contrast to the stainless steel versions of the bipolar plates and the porous transport layers for PEM electrolysers, Umicore MDS coats the bipolar plates and the porous transport layers for PEM electrolysers with titanium, which is much more resistant in the acidic and oxidizing environment of PEM electrolysis. It also helps to maintain conductivity and adapt to high-pressure environments, which is crucial for the longevity and cost efficiency of electrolysers. At least as important is the platinum coating of the components. The coating of the bipolar plates contributes to longevity thanks to its corrosion resistance. Above all, however, platinum improves the performance of electrolysers many times over by acting as a catalyst and increasing the efficiency of electrochemical reactions. It enables a higher electrical potential of the porous transport layers and helps to reduce the amount of energy required for water splitting. This is particularly beneficial when the electrolyzer is powered by renewable energy, which enables the production of green hydrogen.