The Fraunhofer Institute UMSICHT, Sulzbach-Rosenberg site, is researching a process for recycling waste containing chlorine together with the Ostbayerische Technische Hochschule Amberg-Weiden, the University of Regensburg and SKH GmbH. These are to be used to recover critical metals from electronic scrap and other material flows.

Project goals

The "Chlorine Platform" project aims to develop a new raw material recycling process for plastic waste containing chlorine while at the same time recovering supply-critical metals. For many of the high-tech metals under consideration, such as indium or rare earth metals, recycling from end-of-life waste will be possible for the first time. With this technology, it is potentially possible to recover several tens of thousands of tons of HCl and thus several thousand tons of high-tech metals from waste.

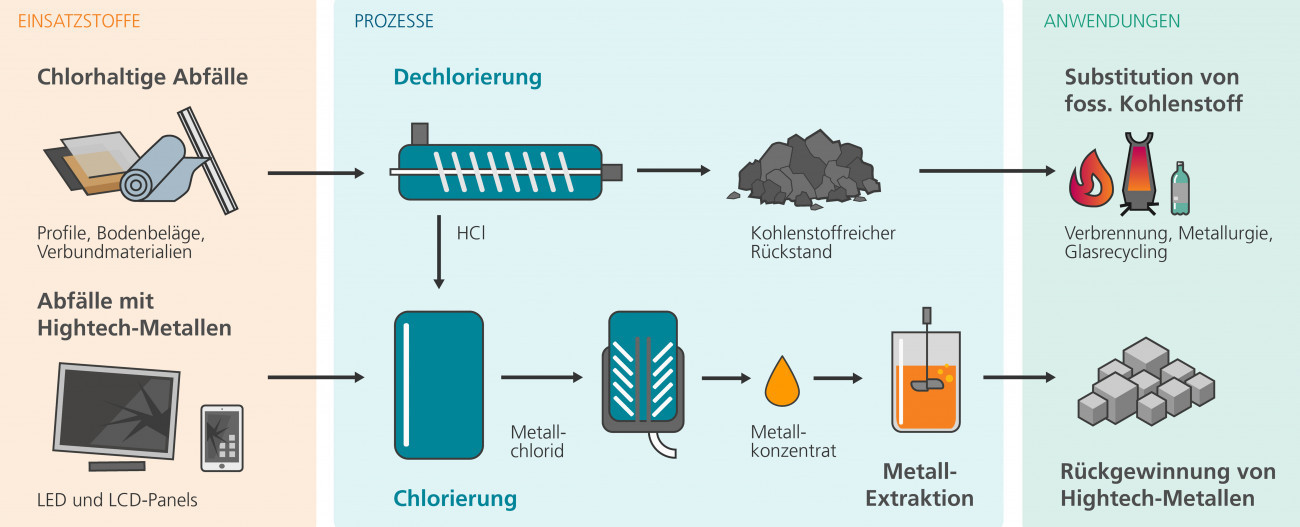

Process diagram of the "chlorine platform" for the recovery of critical metals and feedstock recycling of waste containing chlorine

Process diagram of the "chlorine platform" for the recovery of critical metals and feedstock recycling of waste containing chlorine

Potential users of the technology include waste disposal and recycling companies, but above all the processing and manufacturing industries. Recovered high-tech metals from waste could contribute to securing the supply of raw materials for production processes, greater resilience in supply chains and greater sustainability.

Initial situation

Plastic waste containing chlorine - this mainly includes waste containing polyvinyl chloride (PVC), for example from end-of-life vehicles or the construction sector - is mainly recycled thermally (62% in 2017). The hydrogen chloride (HCl) produced during incineration must be removed from the flue gas at great expense or neutralized and landfilled. This is necessary to prevent corrosion of plant components and the formation of highly toxic dioxins and furans.

As far as the recycling of high-tech metals is concerned, there are already established recycling processes for particularly valuable metals such as platinum group metals (PGM), e.g. in refineries or integrated copper smelters. There are still no optimal recycling routes for the majority of critical metals. These include, for example, rare earth metals or indium, which are required for electronic devices and components such as light-emitting diodes (LEDs), fiber optic cables or LCD panels. These metals usually accumulate in residual or secondary fractions of larger waste streams (e.g. in the recycling of waste electrical and electronic equipment). Mechanical recycling is difficult or even impossible with these types of waste and the metals contained are effectively lost during thermal recycling.

Solution approach

With the help of a thermo-chemical dechlorination step based on the iCycle technology developed at the Fraunhofer Institute UMSICHT, a gas containing HCl is first produced from plastic waste containing chlorine. The HCl is made to react with the metal-containing waste (chlorination), whereupon the metals contained are converted into their metal chlorides. Due to the lower boiling points of the metal chlorides, they evaporate and are deliberately condensed out. This produces a metal-rich, liquid concentrate. Through further process steps, the metals are extracted, separated and converted into marketable target products, which can then be used again in the high-tech industry.

In addition to the gas phase, a carbon-rich solid residue is produced as a by-product. This (chlorine-free) carbonate can be used in production processes, e.g. in metallurgy or glass recycling, as a substitute for fossil fuels.

ForCYCLE II project network

The project "Platform technology for the recycling of waste containing chlorine and recovery of critical metals - chlorine platform" is one of eleven projects in the ForCYCLE II project network led by OTH Amberg-Weiden. The network is developing innovative technological solutions to increase resource efficiency. The ForCYCLE II project network is funded by the Bavarian State Ministry for the Environment and Consumer Protection.