TRUMPF and Fraunhofer IPA conclude research cooperation until 2025. The aim is to develop solutions for networked sheet metal production with artificial intelligence.

The high-tech company TRUMPF and the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart have agreed on a research cooperation until 2025. The aim is to bring solutions for networked manufacturing with artificial intelligence (AI) to industrial maturity. The funding for the project amounts to around two million euros over the next five years. A total of ten employees from TRUMPF and the Fraunhofer IPA are involved in the projects. "TRUMPF wants to further expand its leading position in AI in sheet metal production. That's why we are already investing in future technologies that will help companies achieve major efficiency gains and increase their competitiveness," says Thomas Schneider, Managing Director Development at TRUMPF Machine Tools. TRUMPF and the Fraunhofer IPA have already been working together on the topic of Smart Factory for five years and want to continue previous projects as part of the new research partnership. "TRUMPF has been working with us on the topic of networked production for years because the company - like us - recognizes the developments surrounding Industry 4.0 as a great opportunity. The next few years will be so exciting because they will decide everything. We expect the coronavirus pandemic to act as a catalyst here: Those who are prepared will be able to take massive advantage of the resulting opportunities. So now it will also show whether we have prepared ourselves well for the future with the work in the joint projects," says Professor Thomas Bauernhansl, Director of Fraunhofer IPA.

Future projects should make AI explainable

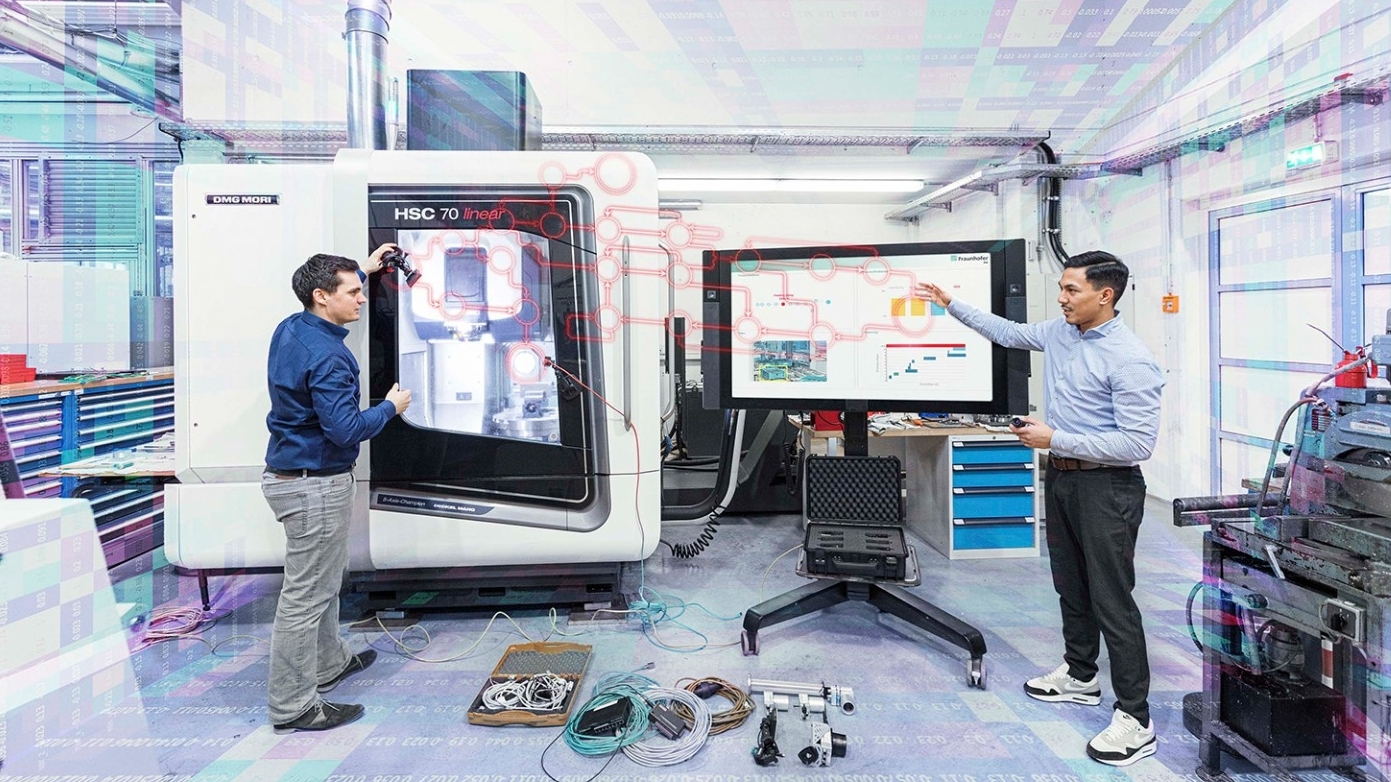

Sorting Guide: One result of the collaboration is TRUMPF's Sorting Guide, which uses AI to support employees in the removal of laser-cut sheet metal components. © TRUMPFOverthe next five years, TRUMPF and Fraunhofer IPA want to develop solutions for better data quality in production, among other things. After all, high-quality data is a prerequisite for achieving an increase in efficiency with AI. In this context, the partners are increasingly researching the topic of "Explainable Artificial Intelligence" (EAI). The aim is to make the way neural networks work comprehensible. Such results are of great benefit to sheet metal production. The results of data evaluation can increase the quality of production and save costs and time.

Sorting Guide: One result of the collaboration is TRUMPF's Sorting Guide, which uses AI to support employees in the removal of laser-cut sheet metal components. © TRUMPFOverthe next five years, TRUMPF and Fraunhofer IPA want to develop solutions for better data quality in production, among other things. After all, high-quality data is a prerequisite for achieving an increase in efficiency with AI. In this context, the partners are increasingly researching the topic of "Explainable Artificial Intelligence" (EAI). The aim is to make the way neural networks work comprehensible. Such results are of great benefit to sheet metal production. The results of data evaluation can increase the quality of production and save costs and time.

New solutions are close to market maturity

The collaboration between TRUMPF and the Fraunhofer IPA on digital manufacturing began back in 2015. The first results are now ready for the market. These include the "Sorting Guide" assistance system from TRUMPF, which supports employees when sorting laser-cut sheet metal components. The AI solution recognizes the removal process and automatically provides the worker with all the necessary information for intralogistics. It clearly displays sheet metal parts that belong together in different colors, for example based on the order, the customer or the subsequent processing step. In this way, the solution replaces accompanying documents, saves time and helps to avoid errors. To build on these successes, the partners are continuing their strategic cooperation.