Efficiency and comfort will have a significant influence on the decision to buy a vehicle in the future. However, in new vehicle concepts, the known measures to reduce noise and vibrations collide with the desire for energy efficiency and weight reduction. System developers are therefore confronted with design conflicts when designing innovative vehicle structures, to which they must respond with new components, materials and development methods. Vibro-acoustic metamaterials promise to make a significant contribution here. However, computer-aided development methods and scalable, economical and quality-assured production processes are still lacking. The aim of the newly launched "viaMeta" research project, led by Mercedes-Benz AG and the Fraunhofer Institute for Structural Durability and System Reliability LBF, is to tap into the lightweight construction potential of future vehicles and to consistently streamline structures. The research partners want to meet the resulting structural-dynamic challenges with vibro-acoustic metamaterials.

In the current state of lightweight structural design, vibration transmission and sound radiation in the vehicle is mainly achieved by flat structures and transmission paths via subframes, coupling elements and bodywork. These are oversized, equipped with broadband effective damping materials or punctual absorbers with high mass to reduce vibrations or provided with support structures for stiffening. However, these measures lead to a considerable increase in weight. This contrasts with the capabilities of vibro-acoustic metamaterials.

Significantly stronger and broadband sound and vibration reduction

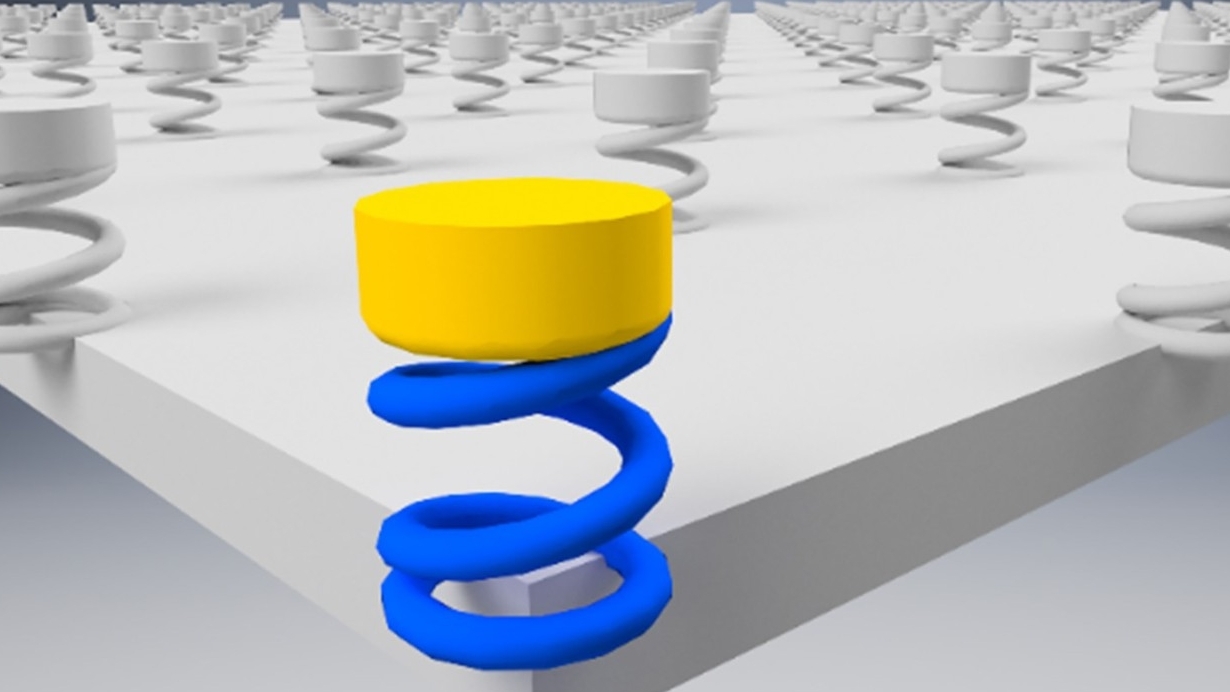

Vibro-acoustic metamaterials consist of a regular, spatial arrangement of identical, very small mechanical resonators. This structure enables them to greatly reduce vibrations in a predetermined frequency range with little additional weight, thus resolving the conflict between very slim structures and optimum comfort. Compared to conventional measures, the clever combination achieves a significantly stronger and broader-band sound and vibration reduction.

Due to the small scale of the unit cells, vibro-acoustic metamaterials can be easily integrated with great design freedom and are compatible with the static, driving dynamics and crash-relevant design requirements relevant to vehicle construction. Compared to active systems, vibro-acoustic metamaterials require no additional energy and are expected to be significantly more cost-effective. The geometry and size of the unit cell depends on the application and the addressed frequency range. Application-specific design concepts, design processes and production methods for use in vehicle construction are still lacking. The "viaMeta" project fills this gap and thus opens up the lightweight construction potential of future vehicles.

Based on the expertise of the partners in the areas of vehicle and component development, material development for vibro-acoustic metamaterials, simulation, optimization and validation, the consortium will develop the design system of the metamaterials and describe the structure and mode of action of the metamaterials. Industry and scientists will jointly select design concepts for the applications and model and simulate them as physically motivated FEM, MBS and system models. By combining highly efficient component models into an overall system simulation, the holistic optimization of the vehicle with regard to vibrations and acoustics will be accelerated in the virtual development phase. The concepts are validated using concrete prototypes for real vehicles and near-series production processes are tested.

The partners in the "viaMeta" project are Mercedes-Benz AG, BOGE Elastmetall GmbH, Novicos GmbH, Institut für Kraftfahrzeuge RWTH Aachen University (ika) and Fraunhofer Institute for Structural Durability and System Reliability LBF.