Oftec Oberflächentechnik GmbH & Co KG, a company in the Ebbinghaus Group, has upgraded its paint stripping facilities. A new paint stripping system was put into operation at the Hagenbach site. The previous, non-automated paint stripping system was designed for aqueous alkaline paint stripping media and was therefore suitable for removing KTL coatings from steel parts. However, the industry is increasingly using light metals or galvanized material, some of which also require paint stripping.

The new system now in operation at Oftec offers a fully automatic process and the choice between aqueous, highly alkaline and soft paint stripping, which is particularly suitable for light metals such as aluminum or die-cast zinc. The system is loaded with material via a roller conveyor with complete product carriers. The worker confirms that there are no more people in the system and ends the input. It is now confirmed outside the system that it is ready for use and a corresponding program is started. The actual paint stripping and rinsing process then takes place fully automatically in the room sealed off from the production hall.

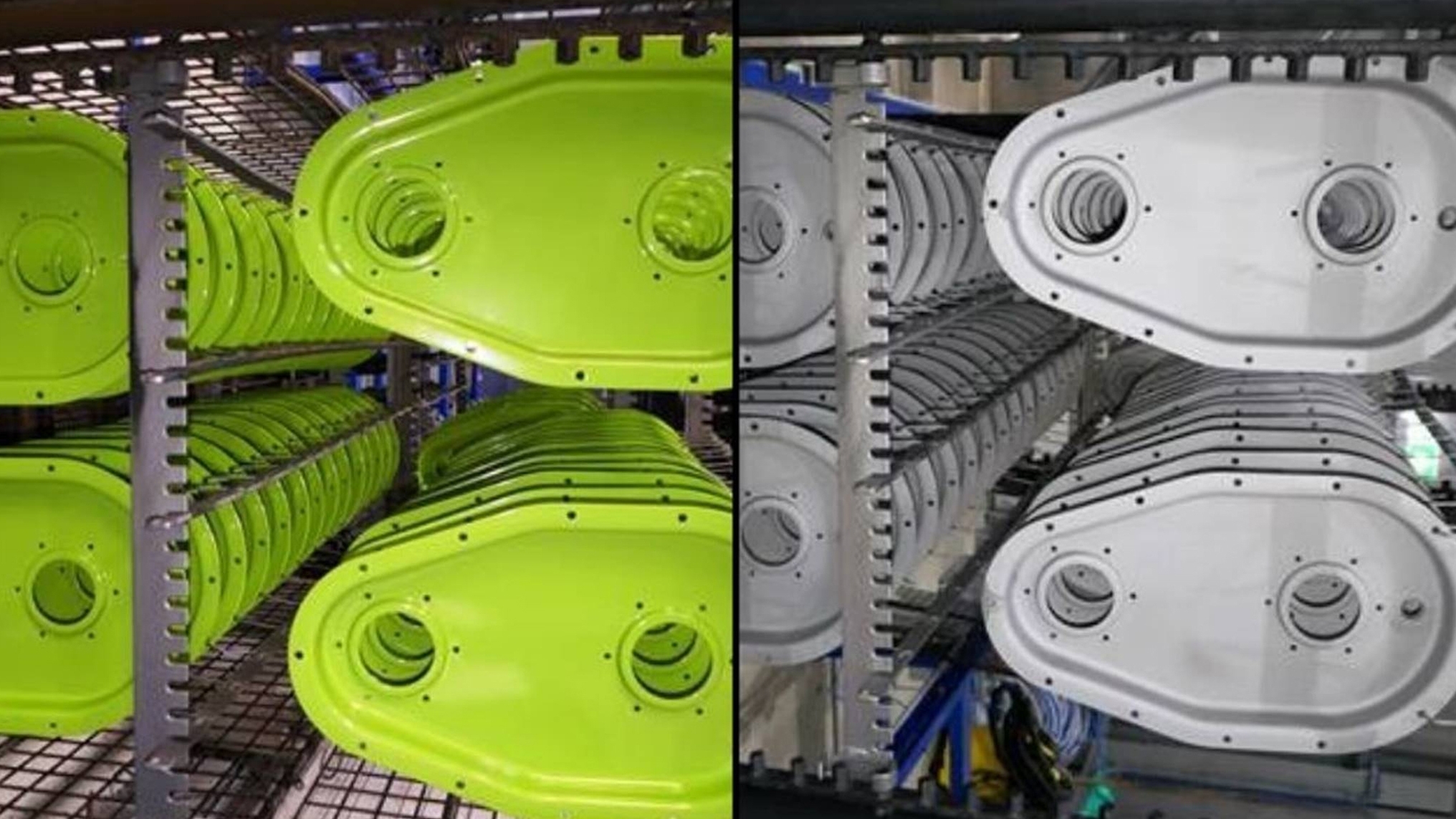

On the one hand, the new system offers enormous progress in terms of occupational safety for employees. On the other hand, different materials can now be treated on site at Oftec, which avoids transportation costs, e.g. to external service providers, and also eliminates the associated time expenditure. The system is designed for the standard product carriers used at Oftec, so that all components that arrive at Oftec for contract coating can also be stripped here. By implementing soft paint stripping, Oftec is also able to strip duplex coatings, such as CDP plus wet paint or powder coating.

A further advantage: if faults in the coating system result in incorrect coating or other defects, the components can now be sent immediately to the paint stripping system. The possibly necessary route via an external service provider with unpacking/repacking, dispatching and a new incoming goods process is no longer necessary. Additives in the rinses also prevent the occurrence of flash rust during the rinsing process. As a result, there is no need for a pickling process in the CDP pre-treatment during the subsequent recoating. This benefits the environment in particular, as less chemicals will be used and the pickling process will have a longer service life.