SurTec has long been active in the automotive, aerospace, electronics, architecture and household sectors with its solutions for surface technology. The new Functional Coatings application area was created through the integration of omniTECHNIK, precote USA and the integration of the bonded coatings portfolio of sister companies OKS and Klüber Lubrication, making SurTec the central provider of coatings for fasteners. The company will be showcasing its expanded portfolio at the upcoming Fastener Fair 2025.

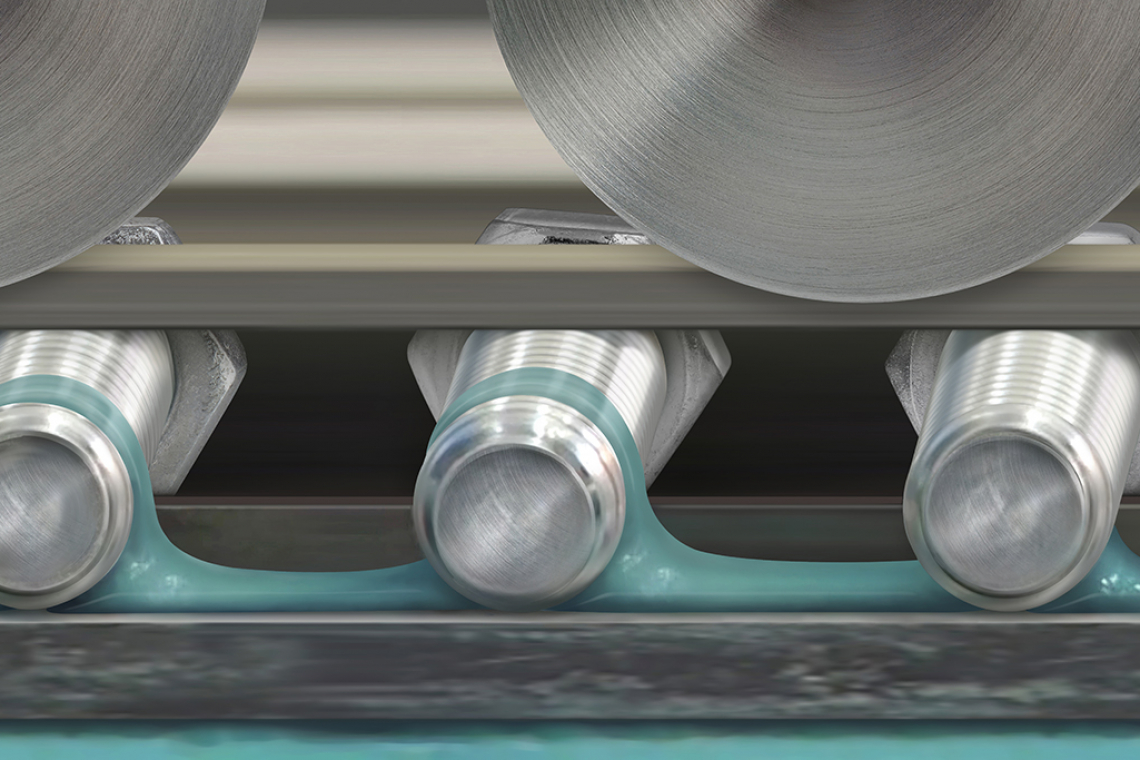

The surface technology specialist SurTec will shortly be presenting its portfolio of functional coatings. The presentation will take place at the Fastener Fair, the trade fair for fastening technologies in Stuttgart from March 25-27, 2025, where innovative solutions for requirements that a coating can meet on an untreated fastener will be on display. These include sealing, securing and friction coefficient adjustment.

Range of functional electroplating technology

In the area of functional electroplating, SurTec will be presenting corrosion protection solutions such as (de)phosphating and zinc electroplating for processing steel. The processes include pre-treatment, coating, passivation and sealing for the highest requirements. "Through strategic acquisitions, SurTec has established itself as a central coating partner for the global fastener industry," explains Dr. Jens Krömer, Director Global Sales & Markets. "The integration of omniTECHNIK and precote USA and the inclusion of anti-friction coatings from sister companies OKS and Klüber Lubrication has created the new "Functional Coatings" application area."

With a special focus on sustainability, SurTec offers innovative PFAS-free solutions for mobility. Microencapsulations such as precote 30 and 80 are already PFAS-free. A PFAS-free version of precote 85, the best-selling pre-coating for threadlocking, will be launched on February 25. These coatings are used by leading OEMs in the bodies and chassis of electric vehicles.

Focus on sustainability

Electromobility designs are increasingly relying on pre-coatings for sealing. precote 15 as a water-based, PFAS-free coating is used in battery packs worldwide. The SurTec Coat 2000 series offers PFAS-free lubricants for sealing rings and plain bearings. SurTec thus offers solutions for sustainable, future-proof mobility and high-performance applications.

Partnership for e-mobility

SurTec's partner is AVL Deutschland GmbH. AVL, a leading company for mobility technologies, is known for its engineering expertise and its extensive sales network, which is supported by a strong presence in Germany. Together, SurTec and AVL are combining their know-how to offer customers greater added value. While SurTec focuses on coatings for fasteners, AVL's strength lies in design, simulation and the integration of components and subsystems in vehicles. Close cooperation from the earliest stages of development is advantageous for optimum results.

SurTec can be found at stand 3-1666, where SurTec and AVL experts will be on hand to answer visitors' questions.

SurTec Dr. Karsten Grünke, CEO SurTec

Dr. Karsten Grünke, CEO SurTec

SurTec, a well-known expert in surface technology, develops, produces and distributes chemical solutions for surface treatment worldwide. Areas of application include industrial parts cleaning, metal pre-treatment, functional and decorative electroplating and functional coatings. SurTec is certified according to the international standard ISO 9001 (quality management). The additional certifications according to OHSAS 18001 (occupational health and safety), ISO 45001 (occupational health and safety management) and ISO 14001 (environmental management) correspond to important corporate objectives. The Bensheim-based company is part of Freudenberg Chemical Specialities GmbH and has 450 employees in 26 countries and is represented by partner companies in more than 20 other countries.

AVL Prof. Helmut List, Chairman of the AVL Management Board

Prof. Helmut List, Chairman of the AVL Management Board

AVL, headquartered in Graz, Austria, is one of the world's leading mobility technology companies for development, simulation and testing in the automotive, rail, marine and energy industries. Based on its own research, AVL provides concepts, solutions, methodologies and development tools for technologies and supports international partners and customers in sustainable and digital transformation. The focus here is on the areas of electrification, software, AI and automation. The company also covers vehicle architectures and platform solutions, including the impact of new drive systems and energy sources, and offers customers tools in areas such as big data, artificial intelligence, cybersecurity and embedded systems. AVL employs 12,200 people at more than 90 locations and with more than 50 Tech and Engineering Centers.

www.avl.com