The process water in mass finishing systems for surface treatment contains abrasion, oil and grease. It is treated and recycled in a centrifuge. Peeler centrifuges are used for large quantities of sludge. The machine manufacturer Walther Trowal has now introduced a new user-friendly, practical and efficient centrifuge.

The process water in mass finishing systems for surface treatment contains the abrasion of the workpieces and the abrasive media, as well as oil and grease. Before it is fed back into the system or discharged into the sewage system, it must be treated. In most mass finishing systems, the process water runs in a closed circuit and is recycled in a centrifuge. The sludge contained in the water settles on the inner walls of its rotating drum. If such large quantities of sludge are produced that manual emptying of the basket is no longer economical, peeler centrifuges are used in which a scraper removes the sludge.

Integrated displacement-force measurement as an essential step towards automation

The basic principle of every centrifuge is the separation of (usually solid) components from a liquid by means of centrifugal force. This principle is used in a wide range of industries, from the pharmaceutical industry and the food industry to paint and varnish production. Another possible application is the treatment of waste water, such as that produced during the vibratory grinding of metals or other materials. Almost all solid particles are removed from waste water, for example. The purified process water can then be fed back into the mass finishing process. A well-known manufacturer of such centrifuges is Walther Trowal, which has been developing and producing process solutions for surface treatment since 1931. Starting with mass finishing technology - the term "Trowalizing" is derived from "Trommel Walther" - Walther Trowal has continuously expanded its range of products. The centrifuges produced are suitable for numerous applications, including tasks where solids have to be separated.

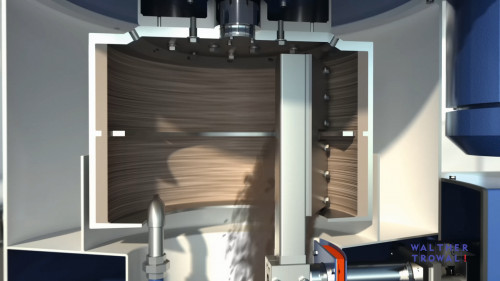

Fig. 2: Interior view of the rotating centrifuge bowl of a ZA 04

Fig. 2: Interior view of the rotating centrifuge bowl of a ZA 04

In the new, compact ZA 04 centrifuge just presented, Walther Trowal has equipped the bowl with a "digital scraper" which is controlled by an integrated displacement-force measurement. This ensures that the scraper always maintains the correct distance from the inner wall. It also enables the machine to be set up automatically: it eliminates the need for all mechanical adjustment activities that previously had to be carried out manually at regular intervals. This reduces the effort and time required for mechanical set-up of the scraper and maintenance to almost zero. In the past, a manual adjustment process was required to adjust the peeling blade; the new system now does this automatically. In addition to the new control system, the engineers at Walther Trowal have also designed the machine to be very compact: It requires around 30% less floor space than its predecessor. In addition, all operating and maintenance elements are accessible from the same side. For the user, this means that he not only saves valuable hall space, but also has great freedom when positioning the machine in his hall.

Reliable separation even from fine rod abrasion

More important than the ease of operation, however, is the result of the wastewater treatment. And here the results are impressive. With the ZA 04 and ZA 06 peeler centrifuges, the solids are separated from the process water at up to 2,417 times the acceleration due to gravity. Oil and/or fines < 1 μm are separated by adding flocculants. The compound used is largely retained! When recirculating mass finishing water, not only water (up to 98 %) but also compound (up to 90 %) is saved. All legal requirements are met and your disposal costs are also reduced. The PLC-controlled, automatically operating ZA 06 cleans up to 2,000 liters of mass finishing process water per hour. The sludge separated in the rotating drum is peeled fully automatically into a sludge container in adjustable cycles. The modular design of the ZA series enables an optimum machine configuration that can be adapted to customer-specific requirements. This includes the choice of different dirt and process water tank sizes, recoolers, additional process water pumps and dosing devices.

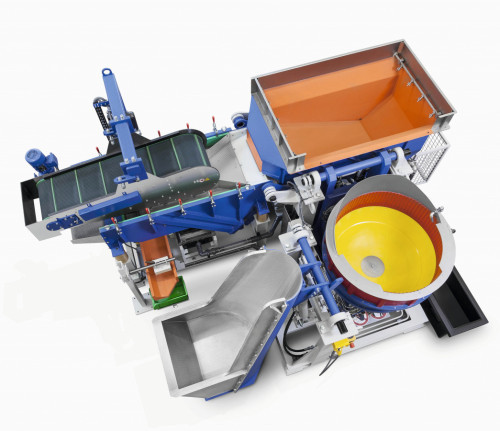

Figure 3: A Turbotron system (TT) as a two-batch system

Figure 3: A Turbotron system (TT) as a two-batch system

In summary, automated systems such as the ZA peeler centrifuges presented here make a significant contribution to sustainable production. This centrifuge will be exhibited at MACH 2024 in Birmingham, UK, from April 15 to 19, 2024. At this international trade fair, Walther Trowal will be presenting a number of innovations for the surface finishing of high-quality metal workpieces along the entire mass finishing process chain. For small parts, Walther Trowal will be presenting a centrifugal machine from the TT series. In this two-batch machine, one batch is processed, for example rounded, smoothed or polished. At the same time, another batch is separated: The workpieces are separated from the abrasive media. In this way, non-productive times are minimized and the system achieves a very high throughput with a small footprint. Together with the new, automated peeling centrifuge, the entire machining process is on display.

Photos: Walther Trowal