The EcoCcompact family is growing in the form of an L and XL version.

The basic principle of the EcoCcompact line of cleaning systems is a single-chamber system operating under full vacuum for cleaning and preserving components with modified alcohols and non-halogenated hydrocarbons. In addition to high cleaning quality and short cycle times, this type of system is characterized above all by maximum flexibility for different cleaning tasks. The systems are therefore suitable for a wide range of applications, from quick degreasing to demanding cleaning tasks with component cleanliness specifications.

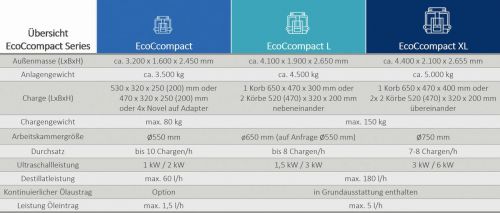

In order to better meet the diverse requirements of general industry, Ecoclean has expanded the cost-efficient EcoCcompact to include the Large (L) and Extra-Large (XL) model variants. The new product family, now with three working chamber sizes and batch weights of up to 150 kg, makes it possible to adapt the capacity and cleaning performance precisely to company-specific requirements. Sophisticated equipment details, an effective washing mechanism and high energy efficiency keep cleaning unit costs low. In addition, the compact plug and play solvent systems can be easily converted from hydrocarbon to modified alcohol.

" Sophisticated equipment details, an effective washing mechanism and high energy efficiency keep cleaning unit costs low. "

Flexibility is required

The diverse product range of the general industry includes workpieces manufactured using casting and machining processes, stamped, bent, pressed and deep-drawn parts, hydraulic and pneumatic components and connecting elements. Depending on the subsequent process or application, the parts manufactured from different materials must meet different, but increasingly stringent particulate and film cleanliness requirements. High throughputs, increased demands on resource efficiency and, in some cases, low margins pose a particular challenge.

With three working chamber sizes and batch weights of up to 150 kg, the EcoCcompact product family makes it possible to adapt the capacity and cleaning performance precisely to company-specific requirements

With three working chamber sizes and batch weights of up to 150 kg, the EcoCcompact product family makes it possible to adapt the capacity and cleaning performance precisely to company-specific requirements

This results in the need to ensure stable, sustainable and low unit costs for cleaning with cleanliness in line with requirements. Ecoclean has expanded the existing EcoCcompact line with the L and XL model variants to form a product family for these tasks. As with its smaller sister on the market, the new larger systems can also be switched between hydrocarbons and modified alcohols (semi-polar solvents) easily and without any conversion work during operation.

An established supplier with its finger on the pulse of the market

The vertical integration of the two standard flood tanks reduces sump formation and prevents the formation of dirt pockets. This results in a longer service life for the baths. The increased distillate capacity of up to 180 l/h and the standard, continuous oil discharge in the L and XL versions also contribute to thisTheSBS Ecoclean Group is a proven supplier of cleaning systems, employs around 900 people and is represented by eleven production sites in Germany and eight other countries worldwide. In addition to the development and production of systems for industrial component cleaning and surface treatment, the Group also focuses on alkaline electrolysis systems for the decentralized production of green hydrogen. The innovation drivers here are the two competence centers based in Germany, which support the global Group companies with technical expertise, research and pioneering developments. The often tailor-made automation solutions help companies from a wide range of sectors such as mechanical engineering, the semiconductor supply industry, precision optics, medical technology, the automotive and supplier industry, micro and precision engineering, aerospace and fastening technology around the world to produce efficiently and sustainably at a high level of quality. The group of companies combines the Ecoclean, UCM and Mhitraa brands.

The vertical integration of the two standard flood tanks reduces sump formation and prevents the formation of dirt pockets. This results in a longer service life for the baths. The increased distillate capacity of up to 180 l/h and the standard, continuous oil discharge in the L and XL versions also contribute to thisTheSBS Ecoclean Group is a proven supplier of cleaning systems, employs around 900 people and is represented by eleven production sites in Germany and eight other countries worldwide. In addition to the development and production of systems for industrial component cleaning and surface treatment, the Group also focuses on alkaline electrolysis systems for the decentralized production of green hydrogen. The innovation drivers here are the two competence centers based in Germany, which support the global Group companies with technical expertise, research and pioneering developments. The often tailor-made automation solutions help companies from a wide range of sectors such as mechanical engineering, the semiconductor supply industry, precision optics, medical technology, the automotive and supplier industry, micro and precision engineering, aerospace and fastening technology around the world to produce efficiently and sustainably at a high level of quality. The group of companies combines the Ecoclean, UCM and Mhitraa brands.

Impressive energy efficiency and sustainability

Like all solvent cleaning systems, the new L and XL versions of the EcoCcompact are characterized by a high degree of flexibility in terms of material compatibility. This means that components made of different materials can be cleaned in one system. In addition, they can also be used in regions where the consumption of water as a cleaning medium is critical and/or the disposal of waste water from cleaning applications is regulated. The prerequisite for this is the suitability of the solvent cleaning process used. At Ecoclean, this can be checked via cleaning tests in the worldwide test centers.

The two new, compact plug-and-play solvent systems have working chambers with diameters of 650 mm (in the L version) and 750 mm (in the XL version). The maximum batch weight for both systems is 150 kg. Powerful, frequency-controlled flood pumps ensure that the working chamber is filled and emptied quickly. During flooding, these pumps also generate a mechanical cleaning effect. This can be further enhanced by an optional, frequency-controlled rotary drive through fabric rotation. Adapted to the cleanliness requirements, the systems can also be equipped with all available process technologies for solvent cleaning, such as ultrasound and PPC.

The increased distillate output of up to 180 l/h and the continuous oil discharge as standard also contribute to the high capacity and performance of the L and XL versions. The vertical integration of the flood tanks also offers advantages. It reduces sump formation and prevents dirt pockets from forming. The result is a longer service life of the baths and thus a reduction in operating costs. For needs-based cleaning and preservation, the two flood tanks included in the basic version of all EcoCcompacts can be supplemented by a third - fully integrated without increasing the installation area. They each have filtration in the supply and return lines with bag or high-performance filters as well as bypass filtration.

In addition to its small footprint, the EcoCcompact product family is particularly impressive due to its comparatively low energy consumption achieved through optimized system technology. Among other things, this is achieved by heating the flood tank and the optional third tank with heat recovered from the distillation process.