With the increasing industrial use of metal 3D printing, the quality, quality assurance and functionality of additively manufactured components are becoming more and more important. In addition to the final surface treatment of additively manufactured metal components, there is a great need for a combined process chain of additive and subtractive processes (ASM). However, before such manufacturing processes can actually be used on an industrial scale, there are still some unanswered questions that need to be clarified, which the multinational Ad-Proc-Add project aims to address.

As in all technological areas, the interest in these processes also increases the quality requirements. For additive manufacturing (AM), this means increased attention to surface quality as well as dimensional, shape and positional tolerances. In addition, the AM and the entire ASM process chain must be economically competitive. The multinational Ad-Proc-Add project is dedicated to precisely these challenges. It is based on close cooperation between companies and R&D institutions from different areas of expertise. The key to success is to consider the entire ASM process chain from start to finish. The additive process is to be improved for optimal subsequent subtractive process steps, particularly with regard to economic factors such as minimal allowances, reduced process forces, optimized support structures and tool wear.

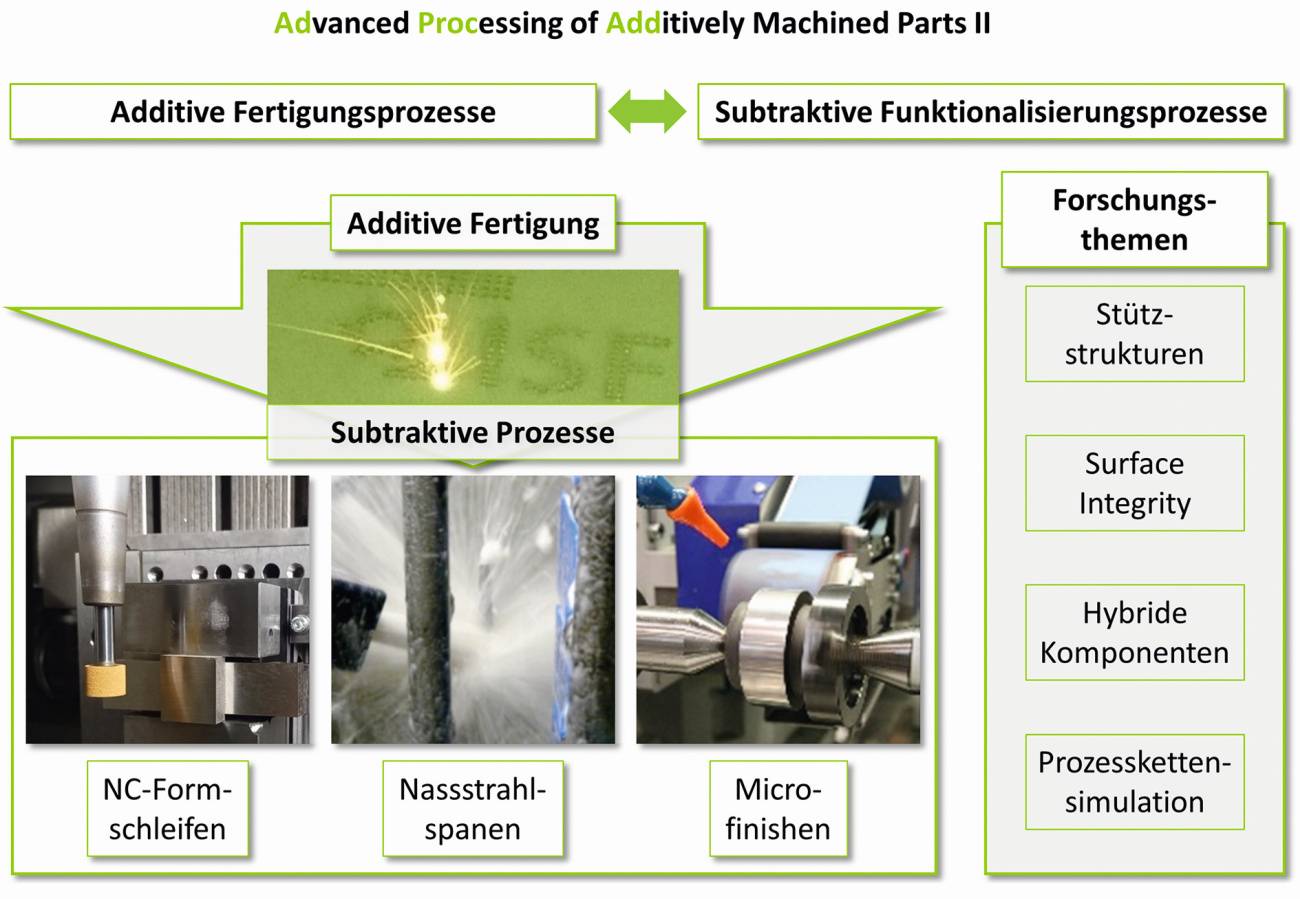

Project focus at the ISF at TU Dortmund University - Interactions between additive and subtractive processes - Photo: ISF

Project focus at the ISF at TU Dortmund University - Interactions between additive and subtractive processes - Photo: ISF

A multinational research project as the basis for successful implementation

3D printing with metals is a relatively young technology compared to conventional manufacturing processes. Many production-related and material-related correlations had to be understood at the beginning before industrial implementation could be considered. In addition, there is still an essential difference to most established manufacturing processes: the printed metal parts cannot be used as printed due to various surface imperfections. The components coming out of the 3D printer all have to be reworked. Can 3D printing and post-processing be combined in such a way that the properties of the end product are changed and optimized? This question is the focus of the ongoing cooperation project "Ad-Proc-Add", which is now in its second funding period.

"Ad-Proc-Add" stands for "Advanced Processing of Additively Manufactured Parts", i.e. the advanced post-processing of 3D printed parts. An international research network with 13 R&D institutions and 60 corporate partners from Austria, Germany, Belgium and Switzerland has been formed for the project. Three types of companies are involved in the project: Suppliers of raw materials, specialists in specific processes and companies interested in the realization of a specific component. The results of the project will be made publicly available after completion and will therefore benefit the entire industry. In addition, the project is supported by a user committee made up of SMEs from all relevant market sectors: Toolmaking, additive manufacturing systems, machine tool manufacturers, software and service providers as well as end users. Intensive communication with the industrial partners ensures the development of industrially relevant and usable results.

The project was initiated and implemented as part of the ecoplus Mechatronics Cluster in Lower Austria and is part of a series of 3D printing projects initiated by the cluster. For more than 60 years, ecoplus has acted as the business agency of the state of Lower Austria and is not only a reliable partner for companies, investors and initiators of regional or international projects, but also serves as an interface between business, politics and science. With the increasing importance of metallic 3D printing and the associated economic interest in the method, the "Ad-Proc-Add" project was launched together with the Austrian Research Promotion Agency FFG as part of the CORNET (COllective Research NETworking) initiative. Due to its great success, the follow-up project "Ad-Proc-Add II" entered its second round in January 2022.

" Ad-Proc-Add II is likely to have an impact on toolmaking, mechanical engineering and manufacturing "

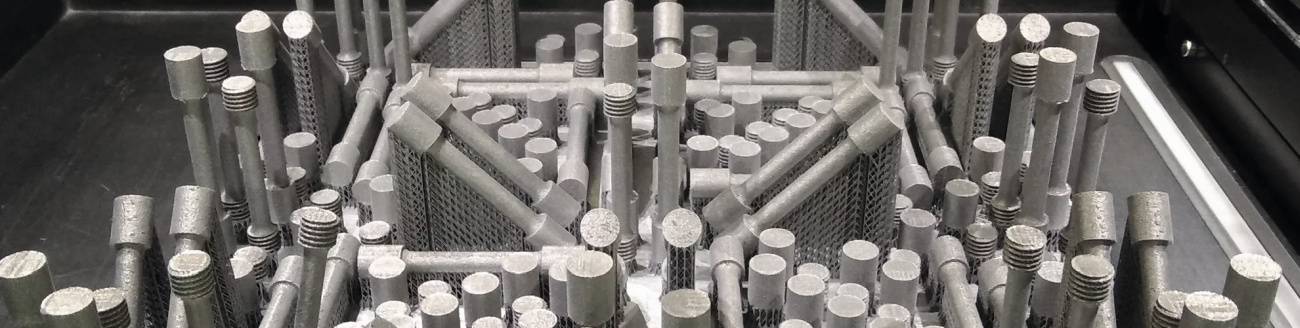

Test components from the Ad-Proc-Add project - Photo: IFT TU Wien

Test components from the Ad-Proc-Add project - Photo: IFT TU Wien

Creating a fundamental understanding of the process across the entire process chain

Looking at post-processing alone is not enough. In order to achieve maximum efficiency and the highest component quality, intervention in the process chain must take place at a very early stage, right from the component design stage. Similarly, adjusting the AM parameters improves surface integrity and increases controllability. This is the only way to identify and exploit hidden optimization potential. In addition, various interactions between ASM process steps are being investigated to enable a hybrid and flexible combination of different AM processes (direct energy deposition DED and laser powder bed fusion PBF-LB/M) and pre-processed workpieces. With the help of numerical additive and subtractive process simulation and data processing, a holistic view of the ASM chain is created so that predefined workpiece properties can be achieved directly and with a minimum of uncertainty. The final goal is to develop a prototype of an ASM process chain knowledge database that can be used to combine multi-sensor data from different process steps. In this way, advanced optimization potentials such as improved toolpath strategies (CAD-CAM optimization) and increased process automation possibilities are to be realized. Various raw materials (aluminium alloys, tool steel, titanium alloys) serve as the basis for the investigations, and both subtractive processes and electrochemical surface treatments (electropolishing, shearing) are used for post-processing. The components were treated using machine hammer peening, abrasive flow machining to smooth internal surfaces and the dynamic electrochemical process of heat treatment, and the results were compared on internal and external surfaces.

One of the main partners is the Institute of Machining Technology at TU Dortmund University. The investigations at the ISF focus on influencing the surface integrity of AM workpieces along the ASM process chain. To this end, the ISF uses a laser powder bed fusion process (PBF-LB/M) and investigates the influences of the subtractive processes NC form grinding, wet blasting and microfinishing.

In Austria, the FOTEC research institute in Wiener Neustadt has been working on all aspects of additive manufacturing for almost 20 years. The importance of post-processing was recognized there early on and the corresponding expertise in post-processing was built up. In its "Laboratory for Manufacturing Innovation (LMI)", FOTEC not only has the necessary infrastructure for the mechanical post-processing, heat treatment and cleaning of 3D-printed components, but also offers electrochemical sheathing for the automated post-processing of 3D-printed metal components.

The project partner IFT, the Institute of Production Engineering at TU Wien, is dedicated to researching the fundamentals of innovative production technologies such as high-performance machining and friction surfacing as well as mechanical surface hammering. The knowledge gained is implemented in industrial applications together with company partners. An important aspect of this is the model-based representation of real processes. New approaches for modeling highly dynamic material behaviour and determining characteristic values, for example for describing the contact between workpiece and tool in the simulation of machining processes, form the basis for this.

" For maximum efficiency and high quality, the process chain must already be intervened in during component design "

Initial project results are promising

Numerous results on additive metalworking processes have already been achieved at a technological level in the course of the project. For example, a deeper understanding of the interdependencies between geometry, internal cavities and requirements for post-processing methods has been gained. There were also many new insights into the interplay between process and design parameters. Some of the participating companies have already been able to integrate additive manufacturing steps into their routine processes.

The Ad-Proc-Add II project is expected to have a significant impact on industrial sectors such as toolmaking, mechanical engineering and manufacturing in the participating countries. However, the project is expected to provide the entire industry with a detailed understanding and technological background for a knowledge-based and effective implementation of innovative AM techniques in various application areas, in addition to fundamental insights. In addition to new tool concepts, manufacturing strategies, design methods and prototype components, service offerings are also to be developed. SMEs in particular should be enabled to derive new processes, products and services. Improved tools and devices can be developed for the growth market of additively manufactured components.

But the goals of the project go even further. The aim is to create access to the additive generation of new types of functionally integrated components, through which small and medium-sized manufacturing companies, fixture manufacturers and mechanical engineers in particular can acquire methodological knowledge for the economical and efficient use of additive-subtractive process chains. Software, system and service providers are to be introduced to the development of new products and services for the implementation and support of additive-subtractive production chains, thereby lowering barriers to entry. The use of additive-subtractive technologies should become feasible with significantly reduced risk, particularly in a difficult investment environment for SMEs. In addition, a digital compendium is to be created that can be used by design and production employees.

The findings, insights, prototypes and experimental results will be presented to the international public in workshops, practical seminars, publications, on the website and at trade fairs.