Trackwise has already made a name for itself with a record-breaking 26-meter-long multilayer flexboard. Now a 72-meter-long flexible 'printed circuit board' has followed. An opportunity to analyze how Trackwise has used the time since Brexit to gradually establish a leading position in Europe.

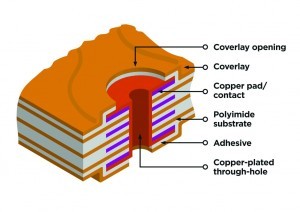

Fig. 1: Standard design of an ML-FPC from TrackwiseWiththe UK's exit from the EU on January 31, 2020, a new era began for the United Kingdom that has not yet been overcome. Following the end of the transition period agreed until December 31, 2020, the country has no longer been part of the EU single market and customs union since January 1, 2021. Brexit has forced companies to rethink their existing development, production and sales strategies and adapt them to the new situation.

Fig. 1: Standard design of an ML-FPC from TrackwiseWiththe UK's exit from the EU on January 31, 2020, a new era began for the United Kingdom that has not yet been overcome. Following the end of the transition period agreed until December 31, 2020, the country has no longer been part of the EU single market and customs union since January 1, 2021. Brexit has forced companies to rethink their existing development, production and sales strategies and adapt them to the new situation.

Trackwise's preparations for the post-Brexit period began in 2018 and 2019 and were described in a Plus article from May 2019 (p. 707ff). It is now interesting to look in more detail at what strategy the PCB company has been pursuing since May 2019, because leaving the EU does not mean that British PCB manufacturers are no longer in competition with companies in the industry in the EU.

As a reminder, the Tewkesbury-based company employed around 40 people in 2019, placing it in the lower end of the mid-market. It was initially founded in 1989 as a design office for printed circuit boards, but in 2000 it was refocused exclusively on PCB production. By specializing in the growing field of antennas and broader RF applications, the company has acquired great and internationally recognized expertise over the years.

PCB technologies are used primarily to manufacture extra-long flexible printed circuit boards, antennas for IT systems and associated RF carriers. The company sees itself as a leading global manufacturer of high-end and time-critical high-frequency, microwave and wireless PCBs. The company has three sites in Tewkesbury, Stevenage (following the acquisition of Stevenage Circuits Ltd.) and Stonehouse. It serves customers in Europe and North America [1].

Based on the company's publications and products, the corporate strategy it has been pursuing since 2019 can be outlined in the following five key areas

- Strengthening technical performance

- Increasing customer loyalty and acquiring new customers

- Expanding production capacities in the short term

- Creating the basis for future expansion

- Strengthening the personnel base, including through experts from the user industry

- Strengthening technical performance

In 2019, Trackwise was already pursuing the goal of using its specialist knowledge of extra-long flexboards to expand its international business, particularly in the aerospace industry. The USA and the UK themselves were a focal point for this. The company's Improved Harness Technology (IHT) is intended to promote the replacement of conventional cable harnesses in the aviation industry. It enables the production of ultra-thin FPCs with very fine conductor paths that meet all possible length requirements(Fig. 1, 2). Other advantages include considerable weight and space savings, better heat dissipation and increased reliability. Competing solutions from other manufacturers are generally limited to FPCs just a few meters long.

In August 2019, the company management announced that it had succeeded in concluding a cooperation agreement with GKN Aerospace (GKN for short) for the production of ice protection systems for aircraft. The Improved Harness Technology was to be further developed and used. The experience gained over the past ten years in the production of flex-long boards (LHTFPCB - Large High Temperature Flexible Printed Circuit Boards), which are able to operate at temperatures of up to 260 °C over long periods of time, even in environments with strong vibrations, was certainly also important for the agreement.

Philip Johnston, Chief Executive Officer of Trackwise, commented on the success at the time: "After almost two years of joint product development, this is a significant milestone in our engagement with GKN, bringing us one step closer to full-scale aerospace production. The associated capabilities are fully aligned with those being developed by Trackwise for Improved Harness Technology. Although aerospace qualification is a lengthy process, the size of the potential end markets means that the future revenue potential for our technology is significant."

The significance of this agreement for Trackwise is clear when you realize that GKN Aerospace is a global company with operations in 13 countries and on five continents. GKN Aerospace designs, builds and supplies aerospace systems and components for use in aircraft of all types and sizes, increasingly based on sustainable technologies. These include the world's first all-electric commuter aircraft.

Fig. 3: New roll-to-roll direct imaging system at Trackwise

Fig. 3: New roll-to-roll direct imaging system at Trackwise

Cooperation agreements such as this one mean that the PCB manufacturer must lay the foundations for a dramatic increase in its overall performance capability. In September 2020, Trackwise logically announced that it was further expanding its production capabilities and capacity by investing in new equipment. A state-of-the-art roll-to-roll direct imaging system was installed and investment was also made in a roll-to-roll laser drilling system for flexible circuits(Fig. 3). The new direct imaging system is located in the manufacturer's recently commissioned Class 7 cleanroom facility and is capable of handling minimum feature sizes of up to 25 µm and also achieving a significantly higher throughput than before. As the system is also suitable for use in a much wider range of optically exposable materials, the investment will allow Trackwise to significantly increase its capabilities and capacity for length-unlimited FPC manufacturing.

The recently acquired high-power diode-pumped UV laser is capable of processing extremely thin and delicate FPCs at high throughput while maintaining processing accuracies of ±20 µm across the entire panel area. An advanced path handler compensates for the continuous acceleration and deceleration of the laminate during production and avoids wrinkling and other stretching problems. The performance and precision of the laser drill significantly reduces cycle times and further improves process quality and yield.

"The ongoing investment we are making in state-of-the-art equipment and cleanroom resources underlines our clear ambition to give our IHT and high-precision printed antenna solutions more traction," assessed CEO Philip Johnston. "Through these activities, we are now much better positioned to take advantage of future market opportunities as they arise - supporting greater volume requirements as well as providing an improved level of quality."

New record: 72 meter long multilayer flexboard

After Trackwise presented a 26-metre multilayer flexboard as a new record in May 2019 and a 52-metre board in 2020, the manufacturer clearly demonstrated its technologically advanced capabilities in September 2021 with a 72-metre ML flex PCB for an industrial application(Fig. 4, 5). The company broke its own record [2].

The long board consists of a polyimide-based laminate with a copper coating and is provided with an organometallic layer to protect against oxidation. The end product has a copper thickness consistency of ±5 µm and is manufactured using IHT. The reel-to-reel copper coating system enables a defined and strictly controlled layer-to-layer resistance and the lowest possible thickness in the end product.

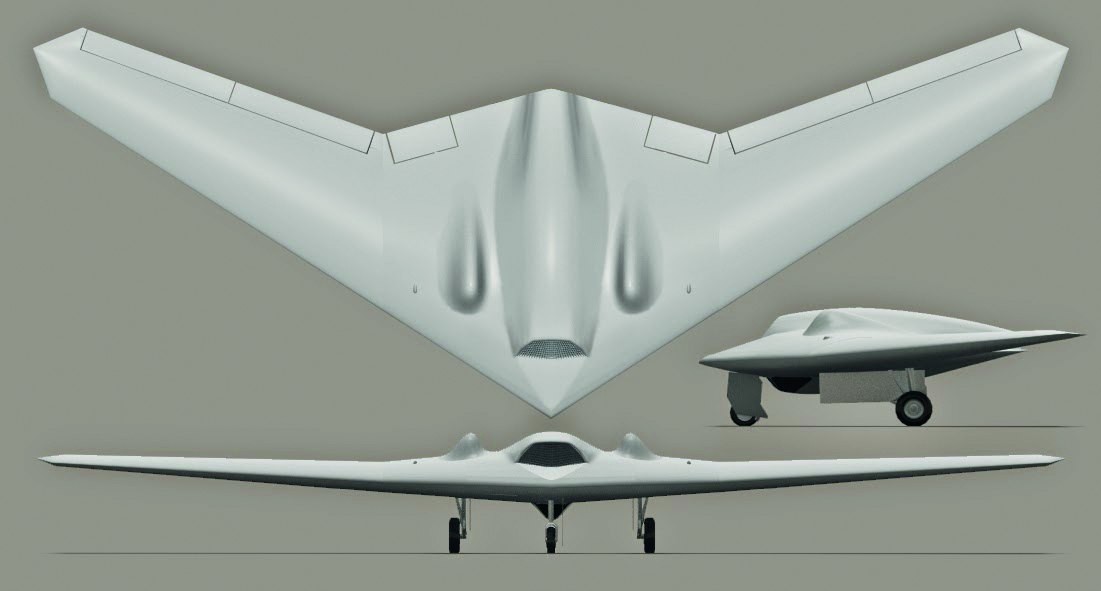

The increasing dimensions of the maximum lengths from year to year are no coincidence. This can be seen by comparing the lengths of the boards with the dimensions of the aircraft that Trackwise has been speculating on supplying since 2019: The Lockheed Martin RQ-170 UAV, for example, has a wingspan of 26 meters(Fig. 6) and the Solar Impulse 2 electric aircraft boasts 72 meters. However, various Boeing aircraft types also have a wingspan of 70 meters or more.

Fig. 6: The Lockheed Martin RQ-170 has a wingspan of 26 meters

Fig. 6: The Lockheed Martin RQ-170 has a wingspan of 26 meters

Improved harness technology for electric cars

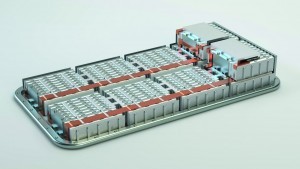

Fig. 7: The batteries in an electric car take up a lot of space In addition to the industrial and aerospace sectors, Trackwise's management also sees the automotive industry as a promising future cooperation partner. Multilayer flexboards can help to increase the battery life and range of electric vehicles, for example by reducing weight. Another important market is medical technology, where the microwires technology used to date can be replaced by cheaper, more reliable and more flexible solutions.

Fig. 7: The batteries in an electric car take up a lot of space In addition to the industrial and aerospace sectors, Trackwise's management also sees the automotive industry as a promising future cooperation partner. Multilayer flexboards can help to increase the battery life and range of electric vehicles, for example by reducing weight. Another important market is medical technology, where the microwires technology used to date can be replaced by cheaper, more reliable and more flexible solutions.

In April 2020, Trackwise received a production order for IHT printed circuit boards with a delivery date of mid-2020 [3]. This first order to support vehicle production followed successful funded development activities last year for an unnamed UK designer and manufacturer of electric vehicles. Trackwise's roll-to-roll technology is used to manufacture FPCs for use at module level in HV and LV circuits in the vehicles' battery packs, reducing part count, assembly time, space and weight. Battery modules for electric vehicles are typically cuboid structures of packaged cells that have well-defined cell connection or monitoring locations that are ideal for flexible PCBs(Fig. 7, 8).

When battery modules are packed together to form a complete vehicle battery pack, the battery modules can be interconnected by long flexible PCBs, sometimes several meters long. CEO Philip Johnston commented: "The electric vehicle industry - and EV battery packs in particular - is one of several growth markets for Trackwise and we are delighted to have been selected by an innovator in this field. Following successful development work over the past year and most recently the acquisition of Stevenage Circuits Ltd (SCL) in early April 2020, this is the next step towards large scale production of IHT."

Fig. 8: Connection solution for car batteries from Trackwise In September 2020, it was announced that the PCB manufacturer had succeeded in concluding a three-year manufacturing and supply agreement for IHT technology with another British electric vehicle manufacturer. The agreement has a potential value of up to £5 million in 2021 with a growth option in 2022 and 2023. This project also involves the supply of flexible IHT PCBs for the high and low voltage parts in the manufacturer's vehicle battery modules and battery packs. The company added that, in line with its growth strategy, it will continue to look for ways to expand and deepen this relationship and look for additional applications for its products in electric cars.

Fig. 8: Connection solution for car batteries from Trackwise In September 2020, it was announced that the PCB manufacturer had succeeded in concluding a three-year manufacturing and supply agreement for IHT technology with another British electric vehicle manufacturer. The agreement has a potential value of up to £5 million in 2021 with a growth option in 2022 and 2023. This project also involves the supply of flexible IHT PCBs for the high and low voltage parts in the manufacturer's vehicle battery modules and battery packs. The company added that, in line with its growth strategy, it will continue to look for ways to expand and deepen this relationship and look for additional applications for its products in electric cars.

More IHT in medical technology

In May 2021, Trackwise signed a seven-year agreement with CathPrint AB, a Stockholm-based company with expertise in the development and manufacture of medical devices. Although CathPrint is an existing customer of Trackwise, the agreement paves the way for a longer-term increase in volume.

CathPrint AB has developed CathPrint Technology, a novel technology platform based on the use of flexible printed circuit boards in catheters, which is currently in the patent process. The agreement relates to the supply of IHT components from Trackwise for use in CathPrint products. The use of IHT enables the cost-efficient integration of electronic components into catheters, probes and tubes, in contrast to today's typical manual production. This significantly reduces labor and costs. The technology enables a semi-automated workflow for attaching wires, electrodes and contacts.

Since 2015, CathPrint AB has filed four US patent applications in which Trackwise's ITH technology plays a key role [4]:

- Low Profile Medical Device with Integrated Flexible Circuits and Methods of Making the Same, publication date 9/24/2020, publication number 20200297280

- Low Profile Medical Device with Bonded Base for Electrical Components, publication date 22.8.2019, publication number 20190254607

- Low Profile Medical Device with Bonded Base for Electrical Components, publication date 22.9.2016, publication number 20160270732

- Low Profile Medical Device with Integrated Flexible Circuits and Methods of Making the Same, publication date 11.8.2016, publication number 20160228061

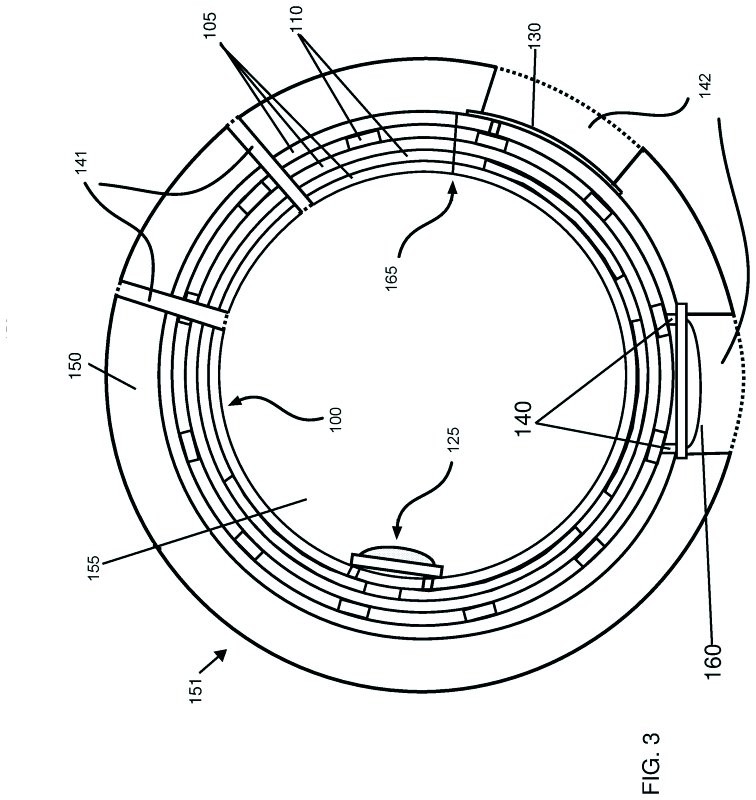

A detailed description of the solution is available at [4] for the respective patent content, including the decisive role of Trackwise's Improved Harness Technology (IHT). The most important drawings of the solution can be viewed at [5], for example the cross-sectional drawing of a catheter with flex circuits shown in Figure 9. The meaning of the description numbers given here is explained in the patent description in [4].

Fig. 9: Cross-sectional drawing of a catheter with flex circuits according to patent number 20200297280

Fig. 9: Cross-sectional drawing of a catheter with flex circuits according to patent number 20200297280

Creating the basis for future expansion

In order to realize its vision for increased performance in the coming years, Trackwise is taking a far-sighted approach and, according to the announcement in May 2021, acquired a 77,000 m² freehold site in Stonehouse, Gloucestershire, for £2.8 million following the fundraising announced in November 2020. One of the company's branches is already located there, so it is likely to be a major expansion. The property, which was selected following an extensive review process due to its excellent layout, location and cost, will enable Trackwise to significantly increase its production capacity to meet the anticipated demand for IHT. Trackwise will install an automated roll-to-roll IHT production line at the site, which is scheduled to be operational in the fourth quarter of this calendar year (i.e. by the end of December 2021). The site has capacity for the installation of a second line in the future.

Takeover of Stevenage Circuits

However, in order to expand its production capacity earlier, i.e. before the planned expansion with the new building in Stonehouse, Trackwise acquired Stevenage Circuits Ltd, a UK-based manufacturer of high-quality flexible and rigid printed circuit boards, in April 2020, probably for around GBP 2.5 million. Located in Stevenage, near Cambridge, the company has been in business since 1971 and manufactures multilayers with up to 44 layers as well as microwave and RF boards, among other things, and therefore has a favorable profile for Trackwise. The minimum L/S values in the advanced area are 50 µm. In the technical area (under development), values of less than 50µm are targeted [6]. This means that Stevenage Circuits is probably behind Trackwise's technical capabilities, so it can be assumed that the parent company will divide up the production tasks according to the technical requirements of the orders.

The transaction will enable the acquirer to rapidly increase production of its IHT boards, expand its customer base and strengthen its technical, sales and operational expertise. It will benefit from the more than 65 employees of Stevenage Circuits. The remaining proceeds from the 2019 fundraising of £5.9 million will be used to fund additional skills and capacity and to hold capital to support growth initiatives, according to management. This includes the further development of Trackwise's intellectual property and know-how. Fundraising was made possible by significant support from existing and new investors.

Strengthening the management team

Because Trackwise is clearly focused on expanding its PCB production for applications with rapidly increasing accuracy and quality requirements, but also has ambitious expansion plans, the company brought in an experienced specialist from the customer side of the boards. It appointed Steve Hudson as Chief Operating Officer. He will support CEO Philip Johnston in implementing the company's strategy and vision as Trackwise expands to serve more customers in its key industries: Automotive, Aerospace and Medical. Hudson has more than 20 years' experience in the automotive, aerospace and medical industries. He began his career at MG Rover before moving into operational and programmatic leadership roles at Bentley Motors and Rolls Royce Aerospace. Most recently, he worked at Williams Advanced Engineering, where he was responsible for the expansion of battery manufacturing capacity, among other things. The CEO therefore has clear views on the division of labor in management: "Steve Hudson will ensure the seamless fulfillment of our contracts against targets as we expand our facilities and grow our team and capabilities."

Another important personnel matter must also be mentioned: In June 2021, Sandeep Heer was nominated as Quality Director of Trackwise Designs plc. He will support COO Steve Hudson, who was appointed in 2020, in implementing expansion plans across the company's key sectors. Sandeep has spent almost 25 years in the engineering industry, working for two of the UK's best known automotive manufacturers. His strengths come from a broad range of experience in manufacturing, supplier quality, continuous improvement of manufacturing facilities, operations and business planning. His career began at Honda, where he quickly rose through the ranks before moving into project management at Magal Engineering and then supplier development at Jaguar Land Rover. Both new additions to Trackwise's management team demonstrate how determined the company's management is to satisfy the highest customer requirements in the best possible way without ifs and buts and to establish Trackwise in the top league not only of British but also, despite Brexit, of European PCB manufacturers - at least in the company's own specialty area. The approach of bringing experienced specialists from the user side into responsible positions at the board manufacturer and thus closing an 'experience gap' should significantly increase Trackwise's chances of success.

References:

[1] www.trackwise.co.uk

[2] www.eenewseurope.com/news/record-multi-layer-flexible-pcb-72m-long

[3] https://polaris.brighterir.com/public/trackwise/news/rns/story/wvk460x

[4] https://patents.justia.com/assignee/cathprint-ab

[5] www.patentguru.com/assignee/cathprint-ab

[6] www.stevenagecircuits.co.uk/capabilities/design_rules