Comparatively little is known about PCB production in India. Dr. Nagaraj Rao, RRRLabs Navi Mumbai, gives us a brief overview.

Printed circuit board from Shogini Technoarts, a manufacturer based in Pune, MaharashtraInIndia, surprisingly, there is still no large-scale production of printed circuit boards. The Indian PCB (Printed Circuit Board) market reached a volume of $4.5 billion in 2022. The market is expected to reach around $12 billion by 2028, growing at a CAGR of 16.6% between 2023 and 2028. Rising usage in consumer electronic products, increasing application in electric vehicles and conducive government policies are some of the major factors driving the market. However, the Indian market is slightly different from the rest of the world. Globally, the flexible circuit market is expected to grow much faster than the rigid PCB market as the former can reduce size and eliminate connectors. There is an increase in the use of rigid PCBs in GPS devices, heart monitors, X-ray machines, temperature sensors, control towers, CT scanners and MRI scanners.

Printed circuit board from Shogini Technoarts, a manufacturer based in Pune, MaharashtraInIndia, surprisingly, there is still no large-scale production of printed circuit boards. The Indian PCB (Printed Circuit Board) market reached a volume of $4.5 billion in 2022. The market is expected to reach around $12 billion by 2028, growing at a CAGR of 16.6% between 2023 and 2028. Rising usage in consumer electronic products, increasing application in electric vehicles and conducive government policies are some of the major factors driving the market. However, the Indian market is slightly different from the rest of the world. Globally, the flexible circuit market is expected to grow much faster than the rigid PCB market as the former can reduce size and eliminate connectors. There is an increase in the use of rigid PCBs in GPS devices, heart monitors, X-ray machines, temperature sensors, control towers, CT scanners and MRI scanners.

Indian PCB manufacturers mainly focus on single/double sided PCBs and multilayer PCBs (in most cases with a layer count of four to six). Most Indian manufacturers follow the 'high mix - medium volume' strategy. Of the 200 or so PCB manufacturers, more than 60 percent are very small and belong to the unorganized sector.

The current demand of $2.38 billion is the combined demand for both bare and assembled PCBs. The current market for bare PCBs is estimated at $1.2 billion - and only 30% of this demand is met by local PCB manufacturers, with the remaining 70% being imported.

High-frequency and high-speed PCBs are more in demand than ever

The increasing demand for PCBs in electronic consumer products such as computers, laptops, cameras, cell phones, portable and audible devices is fueling the growth of the Indian market. Moreover, the increasing use of PCBs in the automotive industry in electric and hybrid vehicles is helping the market to thrive. Moreover, the increasing demand for high frequency and high speed PCBs among the masses is driving the growth of the market.

The Indian government is encouraging the adoption of PCBs by supporting manufacturers to build PCB plants and offering a simple tax regime with less bureaucratic hurdles. Moreover, the increasing popularity of miniaturization and more efficient interconnect solutions in electronic devices is supporting the growth of the market in India. Bare PCBs represent the largest segment as they consist of substrate, metal coating, traces and patterns. Moreover, the rising demand for bare PCBs in consumer electronic products such as computers, tablets and laptops is contributing to the upsurge. The growing preference for the 'Internet of Things' (IoT) and smart home devices among the masses due to the ever-increasing income levels of people is positively influencing the market.

The major challenges faced by PCB manufacturers in the country are inefficient supply chains for raw materials, high investment requirements, difficult access to new technologies and state-of-the-art manufacturing equipment, unfair playing field as companies from competing countries have access to much cheaper financing, poor logistics and infrastructural bottlenecks leading to longer lead times and higher costs, and inconsistent policies at various levels of the electronics industry, from components to end products.

Some of the key PCB manufacturers in India include:

- AT&S

- Cipsa Tec

- DMS Technologies

- Epitome Components

- Hi-Q Electronics

- India Circuit

- Kaynes Technology

- Meena Circuit

- Nano Electrotech

- PCB Power

- Shogini Technoarts

- Sulakshana Circuits

- Vintek Circuit

T-Works and Qualcomm have entered into a grant agreement to build a unique multilayer PCB manufacturing facility at T-Works. The facility will enable rapid manufacturing of up to 12-layer PCBs to accelerate prototyping and development of electronic products. Fuji Electric India will manufacture drives and PCBs in India. Fuji Electric is expected to manufacture 3,500 drives per month in a single shift and plans to produce 200,000 printed circuit boards (PCBs) annually.

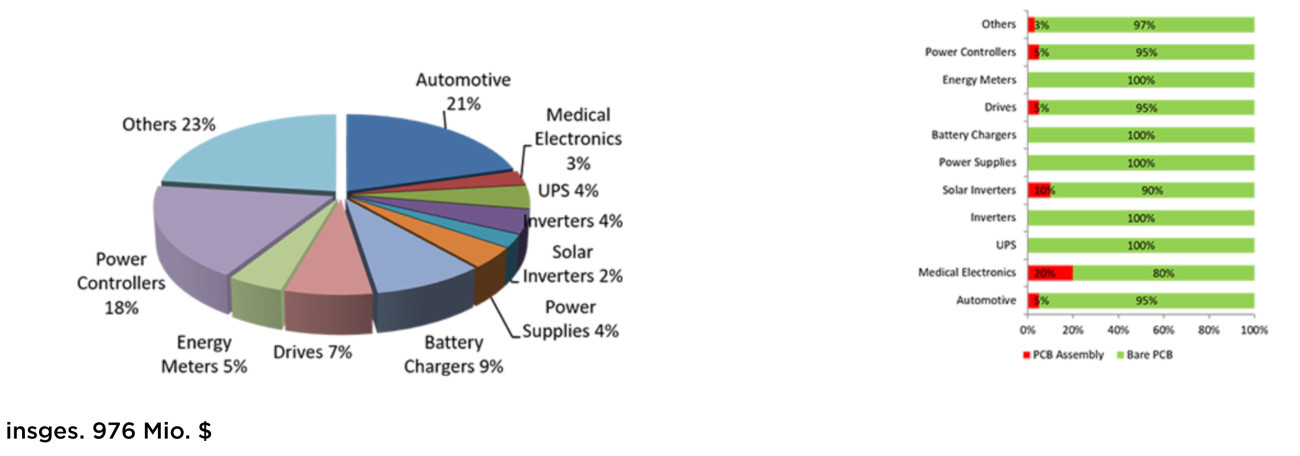

Applications of PCBs in electronic products in India; Chart/Data: Electronic Industries Association of India (elcina)

Applications of PCBs in electronic products in India; Chart/Data: Electronic Industries Association of India (elcina)

Author

Dr. nat. Nagaraj Rao, studied chemistry, technical chemistry, pharmacy and bioprocess engineering in India and partly in Germany, doctorate in Tübingen, post-doc at FZJ Jülich, founder of the SME RRR Labs in India, with a focus on surface technology, organic fine chemicals, biotechnology, sensors and systems as well as the recovery of platinum metals. Website: www.rrrlabs.com