With BAG Analytics GmbH, the B+T Group and Gravitech GmbH have founded a new company for digitalization in the electroplating industry. The core instrument is the ASAP system, which brings together analytics, surface technology, automation and IT. The companies presented the technology at workshops.

The European Clean Deal is an important EU climate policy project and has an impact on all sectors, especially manufacturing companies.

Two workshops at the end of November 2022 at the B+T headquarters in Hüttenberg, North Hesse, focused on the means by which the climate targets can be achieved in electroplating. The B+T Group, Gravitech GmbH and their joint subsidiary, BAG Analytics GmbH, had invited participants to attend. The invitation was accepted by surface coaters of various end products, representatives of the chemical companies supplying the industry and students from this segment.

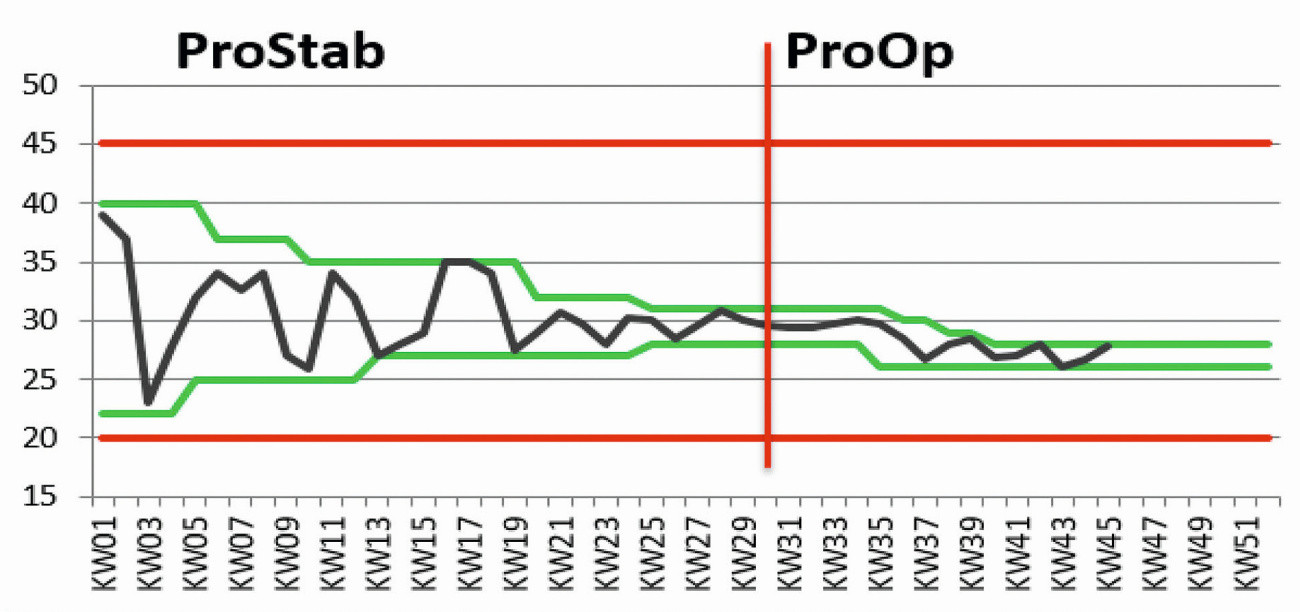

Fig 1: Optimizing the concentration of bath chemicals through tighter analytics and narrower min/max process limits increases product quality and can reduce thecarbon footprint of electroplating baths

Fig 1: Optimizing the concentration of bath chemicals through tighter analytics and narrower min/max process limits increases product quality and can reduce thecarbon footprint of electroplating baths

The European Clean Deal aims to empower consumers in their purchasing decisions for sustainable consumption by providing them with a digital product passport for all physical goods. This digital product passport should contain all information for the entire life cycle, from the design, production and use of the products through to disposal. To achieve this, suppliers must also make their processes more efficient, transparent, environmentally friendly and recyclable.

Digitalization in surface technology

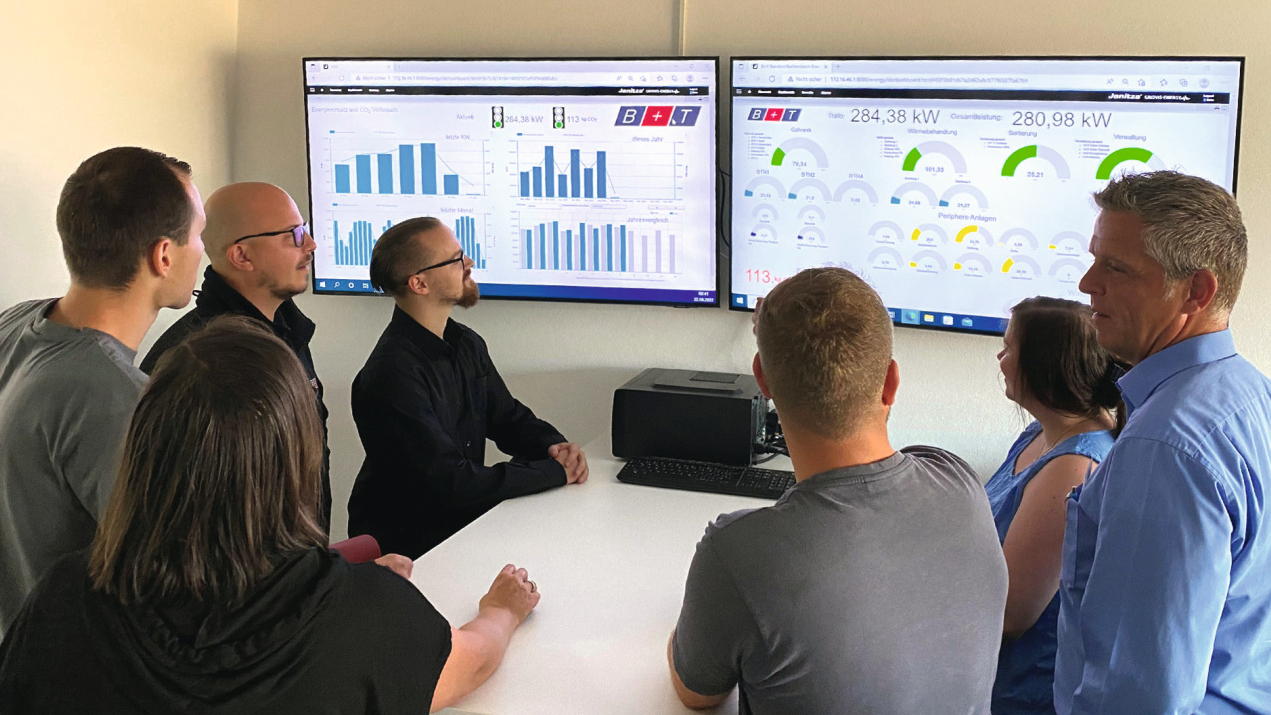

Fig 2: "Best pretzel" means the best possible resultAt thehands-on workshop "Electroplating 4.1",Frank Benner, CEO of the B+T Group and BAG Analytics GmbH, first presented solutions for saving energy and other resources using the example of his coating company. One of the main pillars on the road to climate neutrality continues to be digitalization. Consistent networking throughout the entire production chain is the key to success. To this end, sensors are installed at all individual stations of the production process, right through to the periphery, data is recorded and passed on to the ERP system via interfaces. In the Information Center, the data recorded at a defined time interval on the inflows and outflows of raw materials, consumables and supplies is visualized and evaluated across departments.

Fig 2: "Best pretzel" means the best possible resultAt thehands-on workshop "Electroplating 4.1",Frank Benner, CEO of the B+T Group and BAG Analytics GmbH, first presented solutions for saving energy and other resources using the example of his coating company. One of the main pillars on the road to climate neutrality continues to be digitalization. Consistent networking throughout the entire production chain is the key to success. To this end, sensors are installed at all individual stations of the production process, right through to the periphery, data is recorded and passed on to the ERP system via interfaces. In the Information Center, the data recorded at a defined time interval on the inflows and outflows of raw materials, consumables and supplies is visualized and evaluated across departments.

Following the presentations, B+T Managing Director Norbert Kaufmann gave the workshop participants a lively and illustrative tour of these key figures. Potential savings can be identified at a glance and decisions on optimization can be made as quickly as possible. B+T is involved in various forward-looking research projects that focus on sustainability as well as process efficiency.

What does analytics have to do with sustainability?

Dr. Elke Spahn, Managing Director of Gravitech GmbH and BAG Analytics GmbH, explored this question in her presentation. The classic goals of a company, such as safe and stable processes, optimum quality and effective production with low material and personnel input, can be summarized under the phrase "AAM - All about Money". However, the current supply bottlenecks, energy shortages, rising energy prices and changes to the legal framework are bringing the issue of sustainability in all its facets to the fore: climate neutrality,CO2 footprint, emissions reduction, product passport, environmental compatibility and resource savings.

Fig 3: Agile production requires new tracking systems: The reader at the barrier recognizes the specific RFID of the tag on the tub and passes the information on to the software for further processing

Fig 3: Agile production requires new tracking systems: The reader at the barrier recognizes the specific RFID of the tag on the tub and passes the information on to the software for further processing

This goal can be achieved with the help of analytics, i.e. the systematic examination of processes. In addition to analyzing the operating processes, surface technology also always involves chemical analysis. "As precise as possible and as precise as necessary," is how Dr. Elke Spahn defines the requirements. The accuracy and frequency of the operational and laboratory analysis, monitored manually or automatically, must be adapted to the qualifications of the personnel and the available budget and must be reproducible under real conditions.

Fig 4: The vision and implementation of ASAP originate from Gravitech Managing Director Dr. Elke Spahn and B+T CEO Frank BennerWhenconsidering the possible analysis methods for the entire coating process, photometry for trace analysis in waste water and gravimetric titration for bath monitoring emerged as suitable methods. Users do not need any laboratory knowledge to carry out gravimetric titration and it offers potential savings in terms of time and chemical consumption (Fig. 1).

Fig 4: The vision and implementation of ASAP originate from Gravitech Managing Director Dr. Elke Spahn and B+T CEO Frank BennerWhenconsidering the possible analysis methods for the entire coating process, photometry for trace analysis in waste water and gravimetric titration for bath monitoring emerged as suitable methods. Users do not need any laboratory knowledge to carry out gravimetric titration and it offers potential savings in terms of time and chemical consumption (Fig. 1).

This makes it possible to stabilize and optimize the bath control within narrow limits, so that the process chemicals for each electroplating bath can be reduced and specifically monitored during operation.

Another major potential for saving chemicals in order to reduce theCO2 footprint is offered by looking at the "waste water systems" in the plants. To this end, it is essential to analyze the process water before it enters the "waste water cycle" and to separate the different process waters in separate containers. Analysis and separation of the process water guarantee the correct qualitative and quantitative use of precipitation and neutralization chemicals and prevent the permitted parameter concentrations from being exceeded in accordance with the Waste Water Act.

In the end, it was agreed that analysis is the right way to go, starting with the various intermediate steps before discharge into the wastewater treatment plant. If the interaction of analytics in production, the laboratory and wastewater with the digitalization of processes produces the best possible result, i.e. "Best Pretzel in Town" (Fig. 2) or "Best Coating in Town", the environment is protected as well as the wallet.

Agile production with RFID tracking

Everyone knows them, everyone uses them: RFID codes. What/who is in which place at which time? When people or objects equipped with a battery-free tag pass through a barrier, the change in location is recorded. Well-known examples of this are access control for vehicles and people, time recording at the time clock or tracking objects in warehouse management. If the data is recorded and merged via interfaces, this information can be visualized and thus form the basis for gaining insights and providing decision-making support. Connection to existing ERP systems is also possible (Fig. 3).

However, the potential of smart tags is far from exhausted in many places. Using the example of B+T Galvanik, Fabian Herbst, CDO of the B+T Group, showed how processes can be made more flexible, faster and therefore more agile with the help of RFID technology.

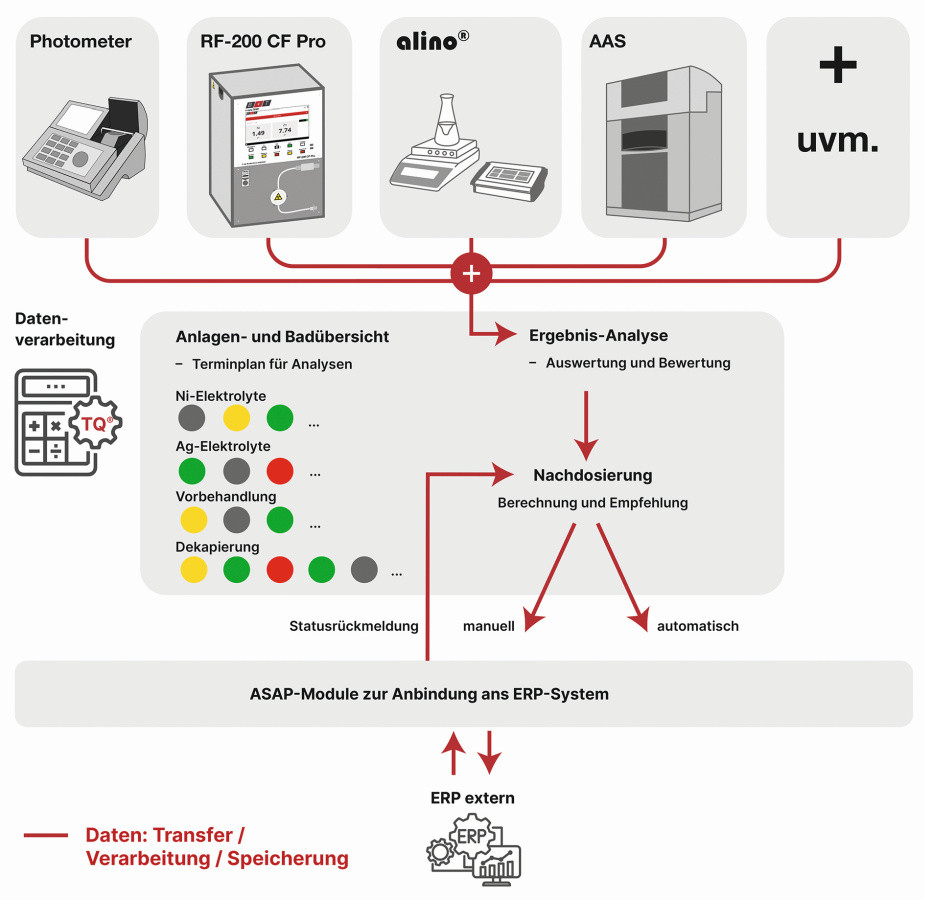

Fig 5: The intelligent, modular ASAP software for analyzing and correcting the bath chemistry and analytics of all operating processes in the company provides information and recommendations for action asap, as soon as possible (Photos: BAG Analytics )

Fig 5: The intelligent, modular ASAP software for analyzing and correcting the bath chemistry and analytics of all operating processes in the company provides information and recommendations for action asap, as soon as possible (Photos: BAG Analytics )

In the Lube Center, the new system for lubricant coating and sealing has a modular design so that individual tanks can be replaced if necessary. If a tub is changed, the RFID sensor sends the information to the system, which then compares it with the order planning software and performs a plausibility check. The production process only restarts after approval.

In addition, the status of the respective contents is also monitored for use, analysis data, throughput and expiry date via the database developed in-house. If baths are not used for a longer period of time, the database informs the laboratory about the performance of necessary, specific analyses, movement, etc. before they are released for reuse.

Handling is simple, standardized and independent of the "human" factor, i.e. his or her qualifications or language skills. The processes are automatically documented and can be traced at any time. A pleasant side effect is that there is no need for routing slips, printing them or filling out forms. RFID also helps to streamline workflows and bring transparency to the process when managing chemicals in the warehouse.

Further examples: Tracking critical spare parts, inventory controls with predictive material reordering or even - a smart farming example from organic farming - tracking cows. As simple as this technology is to use, it is complex to plan and design. The basic question must be: Which processes should be recorded and mapped? What insights should be gained? The experts from B+T ID Solutions offer support during implementation.

Why ASAP - the analysis system for automated processes?

Isolated solutions consisting of PDB (Production Database), LIMS (Laboratory Information and Management System) and ERP (Enterprise Resource Planning) were yesterday, tomorrow it will be ASAP (Analyzing System for Automated Processes).

The founders of BAG Analytics, Frank Benner and Dr. Elke Spahn, share a common vision and passion for innovation and optimized processes in surface technology and beyond. This was the driving force behind the development of ASAP (Fig. 4). Decades of experience in the fields of analysis, surface technology, automation and IT come together here.

Fabian Herbst began by presenting the analysis system for automated processes. ASAP is a platform that connects all sub-areas - production, laboratory, corporate planning.

What does ASAP do? ASAP ...

- records and evaluates analysis results and data

- structures process and operating sequences

- enables tracking and tracing

- increases the efficiency of all processes in production and energy consumption

- documents data from all operational areas and

- standardizes 100% product quality as a standard. Every parameter that has led to this is saved.

As a result, ASAP guarantees process reliability and the defined quality standard, the optimum product, i.e. the "best pretzel". ASAP thus helps to monitor and save energy, chemicals and materials. Ultimately, ASAP enables theCO2 footprint of the products to be verified, monitored and therefore also controlled, i.e. reduced.

ASAP has a modular structure. Each building block, each individual module must first be equipped with master data before it can be used for work. The modules are linked to each other, interact to map the aforementioned key figures and automate the processes.

Possible modules will be: laboratory analysis, calculation/evaluation of analyses, definition of product quality, dosing/peripherals, production, orders, customer management, logistics, warehouse management, KPI, audits, quality and environmental management, data cloud and many more. (Fig. 5).

Fig 6: It should be possible to see at a glance which baths require action

Fig 6: It should be possible to see at a glance which baths require action

The developers have set themselves the goal of making the software simple and intuitive to use. Each user should only see the information that is interesting and relevant to them. The dashboards are configured individually and the tasks are prioritized according to the traffic light system (Fig. 6).

In a further development stage, the plan is to implement AI that supports people in making decisions. However, humans will always define the goal and will ultimately have all decision-making powers.

The workshop participants listened to the speakers with great interest, questioned their statements and engaged with the topics. The exchange with the expert audience took place on an equal footing in a pleasant atmosphere. The participants were keen to identify starting points for optimizing processes for their respective companies and to find solutions.

Action time

In two groups, led by Frank Benner and Edgar Kaufmann, the guests had the opportunity to experience the processes described in the presentation live and in practice during a tour of the electroplating shop.

The small number of operators for the systems at the Hüttenberg site caught the eye. In fact, this phenomenon is due to the stringent digitalization of the entire production process, so that computers and machines relieve people of the sometimes physically demanding and unpleasant tasks. The pending tasks and any error messages are displayed directly on the hall monitors so that the employees can carry out their work in a targeted manner.

Back at the Event Center, the workshop participants were able to lend a hand at the stations set up. The patented alino titrator from Gravitech was met with great interest. Johannes Spahn, partner at BAG, presented the gravimetric titrator and showed interested parties how easy it is to use.

Monika Hofmann-Rinker, Key Account Manager at B+T K-Alpha GmbH, presented the online X-ray analyzer RF-200 CF Pro, which can help with up to four lines of analysis where the alino is limited, namely in the analysis of metals and metal alloys in electrolytes. If required, sample analysis can also be carried out here in one-minute cycles and sharpening can take place immediately afterwards - such direct intervention in the production process is not possible with any other method.

However, ASAP aroused the greatest interest. Here, interested parties had the opportunity to try out some modules themselves and even control the model pump via the software.

Conclusion:

If the programming of the ASAP platform continues to be driven forward so vigorously and can be put into operation with the envisaged functions or modules, it will be a powerful tool for recording theCO2 footprint and can be used to create the product passport. All other approaches to reducing costs, materials used or analysis methods are also important steps towards decarbonizing our industry and achieving climate targets. However, one of the most important steps with the greatest effect will be the conversion of energy-intensive production from gas, oil and otherCO2 emitters to a climate-friendly energy supplier, namely hydrogen.

In the discussions during the workshops, it also became clear that in addition to the existing awareness of costs and efficiency, people also need to be made aware of sustainability: From "AAM - All about Money" to "AAS - All about Sustainability". At the same time, we must not lose sight of the most important players - the people.

Full of impressions and equipped with a snack package for the way home, which of course included Spahn's "Best Pretzel in Town", the participants left much later than planned. Everyone agreed that the workshop had been productive and that they would like to stay in touch.