Many a hot air or blower system has failed when it comes to drying bulk goods. Drying very small parts directly in the container is a tricky business. The coater ODU has reduced the cycle time by 75 % with a suitable drying system

The significant increase in drying efficiency was achieved at Otto Dunkel GmbH & Co KG, ODU for short, from Mühldorf in Bavaria. What previously took 20 minutes now took less than 5 minutes - and with a very good quality result. This special project was realized by the leading international supplier of plug-in connection systems together with the drying system manufacturer Harter from Stiefenhofen in the Allgäu region.

The two companies have known each other for some time, as ODU has been using a sludge dryer from Harter for years. ODU pre-dewaters its electroplating sludge in a chamber filter press and then dehumidifies it homogeneously in the dryer to a dry matter content of 85%. This reduces the weight and volume of the sludge by up to 60 %. Transport and disposal costs are also reduced.

Now that the drying of pins and connectors in the coating plant is well utilized, ODU decided to switch to Harter technology in its production as well. Tests were to show whether condensation drying with a heat pump could deliver the desired result here. "We were very surprised when we saw that our sensitive pins were completely dry in a very short time," reports Michael Antholzner, who is responsible for production in surface technology at ODU. Harter tested several of the baskets with vibration unit in use. These have different diameters and therefore also different quantities of bulk material. In total, ODU produces around 100 million pins and connectors per year. The results in the test series were always the same and equally good for all basket variants. It was therefore an easy step for ODU to invest in the alternative type of drying, which is both efficient and energy-saving.

Fast and flexible

Harter has now implemented a drying system at ODU that consists of several components. Firstly, the Airgenex 9500 dehumidification module, which prepares the required process air. Secondly, two dryers, which are connected to the dehumidification module via insulated pipes. One dryer holds the product carriers with one basket, the other dryer holds the product carriers with two baskets. In the first dryer, the diameters of the round vibration units vary from 180 to 300 mm. In the second dryer, the double baskets are always identical at 120 mm. The respective product carrier is inserted into the dryer, the automatic lid system closes and drying begins. After just a few minutes, the bulk goods are completely and homogeneously dry. This is continuously confirmed by the strict quality control. The drying temperature is 50 °C. This is gentle on both people and materials - products and baskets alike. The dehumidification module, which was installed next to the line at ODU, can also be installed on other floors or on a platform. This is often necessary for space reasons. In this project, the dehumidification system was dimensioned so that additional drying chambers can be connected in the future. ODU is also planning to integrate two additional drum dryers. But how can the complete drying of bulk materials be achieved? And then in several basket sizes?

In baskets with vibration units, pins and connectors are dried completely and homogeneously at 50 °C in 5 minutes. The cycle time has been reduced by 75 % thanks to the efficient heat pump technology

In baskets with vibration units, pins and connectors are dried completely and homogeneously at 50 °C in 5 minutes. The cycle time has been reduced by 75 % thanks to the efficient heat pump technology

Dehumidify and guide air

Harter systems work with extremely dry process air. If air is very dry, it is unsaturated and, for physical reasons, absorbs moisture very quickly. The drying system manufacturer has been taking advantage of this fact for over 30 years. "We pass the dry air over or through the products and can therefore dehumidify them extremely quickly," explains Reinhold Specht, Managing Partner at Harter. He adds: "However, the air must be directed precisely, otherwise it will follow the path of least resistance. Only in this combination do we achieve our successes." This means that every drying chamber is equipped with a special sealing system to ensure that the process air follows exactly the specified path. "A lot of experience and expertise goes into the right air routing," adds Specht. With a technical trick, Harter has succeeded in designing the sealing system of the single-basket dryer in such a way that the bulk materials of all basket diameters used are de facto dry. In turn, ODU can convert the two-basket dryer for use with just one basket in a few simple steps. In this way, the specialist for plug-in connections has the maximum possible flexibility.

There are systems that work in a similar way, but blow the process air outwards. The systems from Harter work in a closed air system. This not only saves a great deal of energy, but also reduces the burden on the production environment, employees and, of course, the environment.

Balance sheet and vision

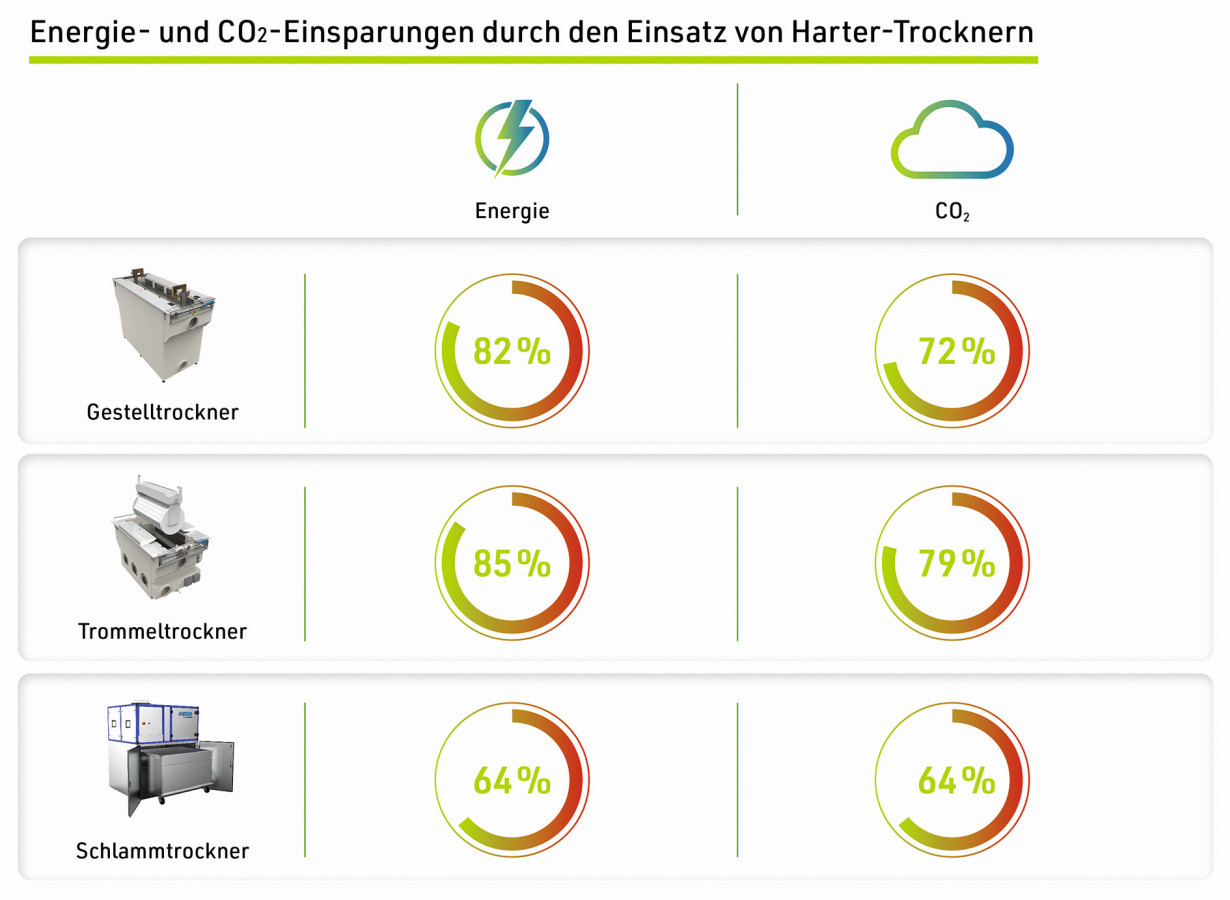

The new system also scores highly in terms of energy compared to the old hot air technology. The two drying chambers each have two fans with a connected load of just 1.6 kW. The entire system has a nominal output of 8.9 kW in production mode. The energy-efficient heat pump system - the heart of the dehumidification module and therefore of every drying system - is responsible for this balance. Customers can save up to 85% on energy costs by purchasing a new system. At ODU, the energy savings amount to 65 % compared to the costs before the new investment. These are figures that were determined as part of a funding application that ODU submitted with the help of a specialist energy consultant. In 2017, the Harter drying technology was classified by the government as a future technology and therefore eligible for funding. The 75% cycle time saving now opens the door for ODU to expand its capacities and drive the company forward. "This is an additional, very big win for us," concludes Antholzner.

www.odu-connectors.com

www.harter-gmbh.de