How the huge aquadome in Berlin suddenly burst at the end of last year remains a mystery. The author of a corrosion protection book published by Leuze Verlag contacted the Galvanotechnik editorial team with an exciting theory. He blames the accident on an effect that also occurs with galvanized surfaces.

Shortly before Christmas 2022, the news spread that the large Berlin aquarium "Aquadom" had burst. Images of the destruction from the lobby of the Radisson Collection hotel were seen on TV screens and the front pages of daily newspapers after it was flooded by 1 million liters of water. Most of the 1500 fish that had lived in the "world's largest cylindrical aquarium" with an integrated real coral reef suffocated in the debris of the burst marine habitat. The aquarium construction had a height of 25 meters. An elevator through the freestanding structure carried visitors from the lobby up to the Sea Life underwater world, which is located in the same building complex as the hotel.

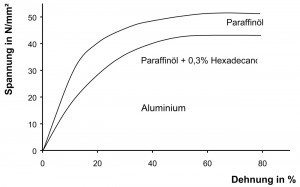

Fig. 1: Stress-strain diagrams of aluminum in an inactive medium and in an active medium (alcohol)Since the accident on December 16, which fortunately resulted in no fatalities and only two injuries, speculation has been rife as to the cause. Investigations are in full swing. The aquarium has been home to a colorful world of fish in 26 degree saltwater since 2003, admired by hundreds of visitors every day. The 14-metre-high water column with 1 million liters of water was surrounded by centimetre-thick acrylic glass. This meant that the glass was under enormous pressure. Initial reports spoke of material fatigue. However, Prof. Karl-Helmut Tostmann, reader of electroplating technology and author of the textbook "Corrosion Protection in Theory and Practice" published by Leuze Verlag, is convinced of a different cause.

Fig. 1: Stress-strain diagrams of aluminum in an inactive medium and in an active medium (alcohol)Since the accident on December 16, which fortunately resulted in no fatalities and only two injuries, speculation has been rife as to the cause. Investigations are in full swing. The aquarium has been home to a colorful world of fish in 26 degree saltwater since 2003, admired by hundreds of visitors every day. The 14-metre-high water column with 1 million liters of water was surrounded by centimetre-thick acrylic glass. This meant that the glass was under enormous pressure. Initial reports spoke of material fatigue. However, Prof. Karl-Helmut Tostmann, reader of electroplating technology and author of the textbook "Corrosion Protection in Theory and Practice" published by Leuze Verlag, is convinced of a different cause.

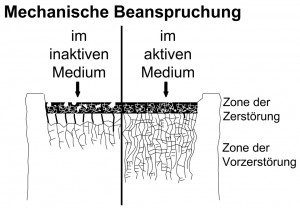

According to Prof. Tostmann, the Rehbinder effect is responsible for the damage to the aquarium. According to this effect, "liquid media containing surface-active substances can influence the strength of a material in the surface area" [1]. This facilitated deformability due to interfacially active substances is called the Rehbinder effect. For the corrosion protection book published in 2017, Prof. Tostmann drew on sources in old GDR reference works about the material technology phenomenon that leads in particular to the deformability and "surface disintegration" of acrylic glass, but also of metals (Fig. 1). The book contains an interesting diagram showing the mechanical stress in active and inactive media for crystalline materials such as acrylic glass (Fig. 2).

While the Rehbinder effect only leads to a change in strength in metallic materials, which can, however, lead to deeper intercrystalline cracks, materials such as glass, ceramic materials and plastics are significantly more affected. Prof. Tostmann writes in his book that damage caused by stress corrosion cracking has become known in these materials. "When I used to go to the glassblower in the laboratory and a tube was cut there, he would scratch it, then wet a finger with saliva and apply it to the glass tube. The tube then broke unusually easily," said Prof. Tostmann, describing the practical effects of the Rehbinder effect in an interview with Galvanotechnik.

Fig. 2: Influence of surface-active media on the mechanical disintegration of crystalline materialsThesurface disintegration in this case is caused by the surfactants contained in saliva, which are also a component of normal household cleaning agents such as Pril. Even a small crack can be the trigger. And in the example, it was "only" glass. According to Tostmann, acrylic glass is much more susceptible to the Rehbinder effect (Fig. 3). However, the Rehbinder effect is insignificant if there is no tension - which was not the case in the aquadome.

Fig. 2: Influence of surface-active media on the mechanical disintegration of crystalline materialsThesurface disintegration in this case is caused by the surfactants contained in saliva, which are also a component of normal household cleaning agents such as Pril. Even a small crack can be the trigger. And in the example, it was "only" glass. According to Tostmann, acrylic glass is much more susceptible to the Rehbinder effect (Fig. 3). However, the Rehbinder effect is insignificant if there is no tension - which was not the case in the aquadome.

The Rehbinder effect is also known in electroplating technology, according to Prof. Tostmann: "We know this in electroplating with mercury on brass or with brass embrittlement". Prof. Tostmann is certain that, because the stresses in the aquadome are applied to the entire container and there is hydrostatic pressure everywhere, a small crack somewhere, which is later run over with a washcloth, is enough to trigger an accident in the long term.

There have also been cases of acrylic breakage caused by detergents, he recalls. These concerned underfloor heating systems in which acrylic glass was used. After installation, these floors were cleaned with normal household detergents, which is said to have led to numerous cases of damage.

The acrylic pane in the car, on the other hand, is not at risk, he says, giving the all-clear. It is not under tension, which is why contact with cleaning agents containing surfactants is not dangerous. The investigation into the cause of the Berlin aquadome therefore remains exciting. Prof. Tostmann is very sure of himself - but whether stress corrosion cracking will one day actually be admitted as an official cause is written in the stars.

Fig. 3: Stress corrosion cracking of acrylic glass caused by a surface-active contact adhesive (Images and graphics: K. H. Tostmann: Corrosion protection in theory and practice)

Fig. 3: Stress corrosion cracking of acrylic glass caused by a surface-active contact adhesive (Images and graphics: K. H. Tostmann: Corrosion protection in theory and practice)

For comprehensive information on corrosion protection, we recommend the specialist book by Prof. Karl-Helmut Tostmann.

INFO

Prof. Karl-Helmut Tostmann

is now retired and most recently taught surface technology at Aalen University of Applied Sciences. He has worked at DECHEMA Gesellschaft für Chemische Technik und Biotechnologie and also at the Steinbeis Foundation in Stuttgart, where he was an industrial consultant for damage and wastewater issues. This often involved damage analyses, mainly for pipes.

Literature

[1] K. H. Tostmann: Corrosion protection in theory and practice, Leuze Verlag, 1st edition, Bad Saulgau (2017), pp. 132-134