Around 1840, a commission of five scientists was formed at the Académie des Sciences in France under the leadership of the respected Jean Baptiste Dumas [1] to report on the methods proposed in the remarks of Professor de la Rive in Geneva in the quote: "long ago gave me the idea of whether it might not be possible to dissolve gold by means of an electric current in such a way that the gold is deposited molecule by molecule on the object to be gilded" [2] for gilding silver and platinum wires using the immersion process.

Auguste Arthur de la Rive was a Swiss physicist (1801-1873)The French Ministry of Finance was also very interested in this topic, as there were fears that the purity of the metals gold and silver used in French coins would decrease. The ministry also hoped to be able to prevent potential fraud with the new and unknown processes of the time. Gilding from aqueous solutions was particularly promising and therefore worthy of investigation, as this technique did not negatively affect the minting of the coin [3].

Auguste Arthur de la Rive was a Swiss physicist (1801-1873)The French Ministry of Finance was also very interested in this topic, as there were fears that the purity of the metals gold and silver used in French coins would decrease. The ministry also hoped to be able to prevent potential fraud with the new and unknown processes of the time. Gilding from aqueous solutions was particularly promising and therefore worthy of investigation, as this technique did not negatively affect the minting of the coin [3].

If we look back today at what developed in the field of plating with gold and other metals at that time, this era can be described as a breakthrough for galvanic plating for industrial applications.

Until then, the classic process used for gilding metals such as iron was the amalgam process, in which the object to be coated was immersed in mercury containing the dissolved gold and then coated with gold after the mercury had been evaporated by a subsequent heat treatment. By repeating the process, the thickness of the gold layer could be increased accordingly. The toxic effect on human health was correspondingly great, so that the workers in this environment fell ill after a short time and died early, which is why "in 1816 Mr. Ravrio, driven by a noble sense of humanity, awarded a prize to anyone who made this art, which he himself practiced with distinction for a long time, less unhealthy" [4]. Thus, in the early years of the 19th century, much experimentation was carried out to enable gilding on the basis of aqueous solutions, which, however, were based on the dipping reaction of the precipitation of the precious gold on a base material. As we know from our experience today, these gold coatings are not corrosion-resistant and had to be repainted at the time.

Interest therefore grew in developing an aqueous alternative to the amalgam process with a gold coating of comparable thickness. This drove researchers to experiment with electroplating using Voltaic columns [1].

At this time, Michael Faraday was working on electricity and the effect of electric current. There were still no units such as electrical current and voltage or electrical resistance. These were not defined until 1882 at the "Electrical Conference" in Paris. This was also the time when people began to agree on terms such as electrodes, anode or cathode or electrolyte. The current flowed from the zinc pole to the copper pole or later from the positive pole to the negative pole and resulted in a galvanic accumulation (deposition) in this direction. Electrons were later discovered to flow in exactly the opposite direction, which still causes us technicians occasional problems with reversal today. Faraday [5, 6] suggested the following on this subject:

"Instead of the name ... the author (Faraday, editor's note) suggests the expression electrod. The surfaces of the decomposing body, at which the positive current of electricity enters and leaves, are called the Eisod, these the Exod. Bodies which are decomposable by the electric current are called electrolytes, and when they are electrochemically decomposed they are said to be electrolyzed; the substances themselves, which in such cases are set at liberty, are called cetodes, and the terms zeteisode and zetexode are used according as the substance passes in one or the other direction" [sic!]

George Richards Elkington, authoritative founder of electroplating in England (1801-1865) One of the main problems in the development of gilding solutions was to find suitable gold salts that could be dissolved stably in water. The most frequently documented experiments were concerned with dissolving gold in aqua regia and transferring it to an alkaline solution. Following this approach, the far-sighted and tenacious industrialist George Richards Elkington engaged in experiments, the results of which he quickly turned into usable processes. His business acumen was accompanied by a strategy of patenting the newly developed processes and buying up all relevant patent rights in France and England. In 1838, he filed his patent 8447 in several countries (US741A [7]), which made technical gold plating without external current possible.

George Richards Elkington, authoritative founder of electroplating in England (1801-1865) One of the main problems in the development of gilding solutions was to find suitable gold salts that could be dissolved stably in water. The most frequently documented experiments were concerned with dissolving gold in aqua regia and transferring it to an alkaline solution. Following this approach, the far-sighted and tenacious industrialist George Richards Elkington engaged in experiments, the results of which he quickly turned into usable processes. His business acumen was accompanied by a strategy of patenting the newly developed processes and buying up all relevant patent rights in France and England. In 1838, he filed his patent 8447 in several countries (US741A [7]), which made technical gold plating without external current possible.

Almost simultaneously around 1840, the composer and chemist Henri-Catherine-Camille comte de Ruolz in France and the surgeon John Wright in England were working on the dissolution of gold in cyanide media, which the Swedish chemist Carl Wilhelm Scheele had previously published in his "Dissertation on Prussian Blue" in 1783 with his observation that the insoluble gold cyanide can be dissolved in a potassium cyanide solution [1, 8]. With the realization that gold could be electrolytically deposited on metals from such aqueous gold solutions using Volta's columns, von Ruolz and Wright developed the first processes for the galvanic deposition of gold and other metals based on cyanide electrolytes. Wright met Elkington in 1840 and sold him his development, which he immediately included as an addition in a previously submitted improved patent specification for plating with the aid of galvanic current and promptly filed in several countries such as England, France, Prussia and others. As a result, Elkington's invention was published on December 8, 1840, and Ruolz's on December 19 in France - with the same subject matter - only 11 days apart [3].

But let us return to the above-mentioned work of the commission of the French Ministry of Finance, which dealt with the potentially suitable processes for coin gilding [3]. The commission was already familiar with the methods of electroless gilding that Elkington was already practicing in France and England at the time. Elkington therefore sent an agent to Paris to present his patent to the Commission, which was comparable to the Ruolz process already known to the Commission, although it had been filed in France a few days earlier than Ruolz's patent. The patent specification and the products presented aroused sufficient interest on the part of the Commission to now also take a closer look at the processes according to Elkington's patents. It was not so much a question of clarifying the patent law issues, but of providing proof of scientific and technical functionality. Demonstrations of the processes took place before the commission, and John Wright, the actual inventor of Elkington's patent, also traveled to Paris for the tests.

The testing of all these processes was carried out in great detail. The report of the test commission was divided into three parts; the first part dealt with the wet process as used by Elkington on a "large scale" (Elkington I), the second part with the galvanic process of the same (Elkington II) and the third part with the process of von Ruolz (Ruolz). The power supply was a Volta column with "a dissolution of sulphuric acid copper and common salt of 10° Baumé; 6 pairs of plates were used, each with a side length of 2 decimeters."

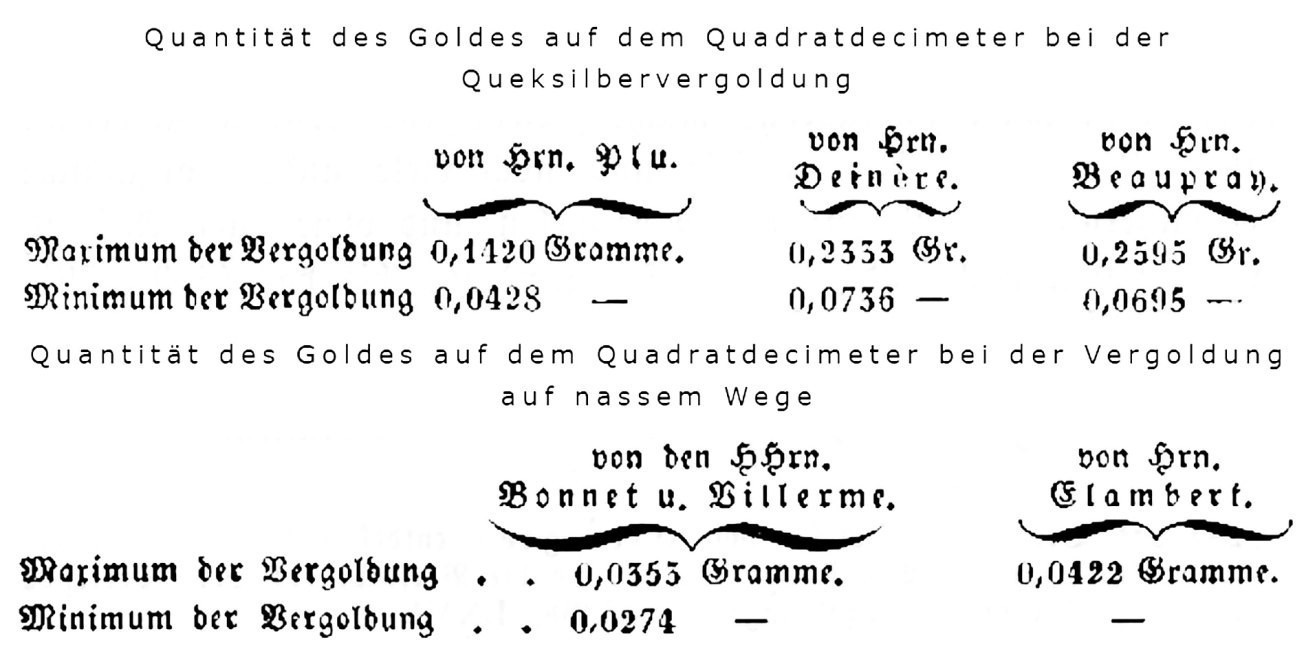

Comparison of fire gilding and wet chemical gilding

Comparison of fire gilding and wet chemical gilding

In December 1841, the commission reported on the results of the comparison of the processes, not only with regard to the gilding experiments, but also the deposition of other metals. Particular attention was paid to the layer thicknesses achieved. The report came to the following conclusions:

ElkingtonI: The electroless process could not replace mercury gilding in most cases, as the best gilding by this method, at 0.0422 g/cm2 gold, was not as good as that of the worst mercury gilding at 0.0428 g/cm2.

Elkington II: According to the report on the process: "Mr. Elkington takes 31.25 grams of gold converted into oxide, 500 grams of hydrocyanic potash and 4 liters of water, boils the whole for half an hour, after which the liquid is ready for use. It gilds very quickly when boiling and more slowly when cold." Brass, copper and silver were gilded in the experiments. It turned out that approximately 0.05g of gold was deposited every minute. After six consecutive weighings, it was found that the quantity was always the same in the same amount of time, so the experiment was no longer continued. The thickness of the gold layer could therefore be increased at will and measured according to the duration of immersion. The fact that potassium cyanide was very rare and expensive at the time and that the process was therefore assumed to be more expensive than mercury gilding was a negative factor in the assessment.

The Commission devoted more time to von Ruolz's many processes and more comprehensive series of measurements were also published, which suggests a national preference for the work of its own citizen von Ruolz.

From the Commission report on von Ruolz: Here are all the tests:

"l) cyan gold dissolved in simple cyan potassium; 2) cyan gold dissolved in yellow cyan iron potassium; 3) cyan gold dissolved in red cyan iron potassium; 4) chlorine gold dissolved in the same cyan compounds; 5) gold chloride chlorine sodium dissolved in carbonic acid sodium bicarbonate; 6) sulphur gold dissolved in neutral sulphur potassium" were well done and were also better documented. Very good results were achieved with all common substrates such as silver, copper, brass and bronze [sic!]

In addition, tests were also carried out on localized covering with simple varnish, whereby the layer thickness could be increased in the uncovered areas. A brass bowl could be gilded in such a way that it could withstand "boiling nitric acid to perfection".

Tabular representation of the series of measurements

Tabular representation of the series of measurements

As an example of a series of measurements, the sample was weighed 12 times at intervals of 2 minutes at 35 °C and an average deposition quantity of 0.0296 g was determined. It was concluded that these deposited quantities were quite regular and, with regard to the influence of temperature, it was clearly evident that the deposition rate increases with the temperature of the electrolyte.

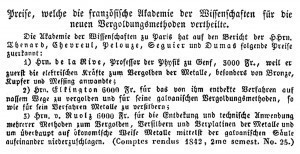

Publication of the award Further, similar experiments were devoted to the deposition of silver, platinum, copper, lead, tin, cobalt, nickel and zinc in this treatise.

Publication of the award Further, similar experiments were devoted to the deposition of silver, platinum, copper, lead, tin, cobalt, nickel and zinc in this treatise.

Six months later, in mid-1842, the commission of the French Academy of Sciences in Paris awarded the prize of 3000 francs to de la Rive for the application of Volta's column for the gilding of metals, 6000 francs to Elkington for his galvanic gilding method and also 6000 francs to von Ruolz for "the industrial application of a variety of gilding and silvering agents" [9].

The treatise and publication of the commission met with international approval and was taken up by many well-known discoverers such as Becquerel, Fehling and Jacobi in order to optimize their processes accordingly. Elsner carried out many of the experiments described at the Königliches Gewerbe Institut in Berlin and published the results in his comprehensive book "Die galvanische Vergoldung und Versilberung, sowohl matt als glänzend, so wie die Verkupferung, Zinnung, Verbleiung, Verzinkung, Bronzierung, Verplatinierung und Vernickelung metallener Gegenstände auf demselben Weg" [10], which is freely available to view online via Google. The Elkingtons, George Richards Elkington and his cousin Henry, eagerly acquired further rights to patents, including the gilding process developed by Werner von Siemens, and fought long-lasting patent disputes in lawsuits. The Elkington company in Birmigham made a name for itself that was known well into the 20th century. Goods from this company are still highly traded on eBay, for example.

Literature

[1] Hunt, L.B.: The Early History of Gold Plating, Gold Bulletin, V6, 1973, 16-27

[2] Rive, de la, A.A.: Ueber ein elektrochemisches Verfahren zum Vergolden des Silbers und Messings, Polytechnisches Journal, Vol. 76, 1840, 297-301

[3] Dumas, J.B.: Elkington's u. v. Ruolz's Verfahrungsarten zum Vergolden etc., Polytechnisches Journal, vol. 83, 1842, 125-145

[4] NN.: Péligot, on Elkington's gilding by the wet method, Polytechnisches Journal, vol. 82, 1841, 371-375

[5] NN: Faraday's investigations on electricity, Polytechnisches Journal, Vol. 52, 1834, 354-359

[6] NN.: Supplement to Faraday's experimental investigations on electricity, Polytechnisches Journal, Vol. 54, 1834, 223-224

[7] US patent US741A, Espacenet, available online

[8] Williams, G.: The Cyanides of Gold, Gold Bulletin, V11, 1978, 56-59

[9] NN: Prizes awarded by the French Academy of Sciences for the new methods of gilding, Polytechnisches Journal, Vol. 87, 1843, 154-155

[10] Elsner, L.: Die galvanische Vergoldung und Versilberung, sowohl matt als glänzend, so wie die Verkupferung, Zinnung, Verbleiung, Verzinkung, Bronzierung, Verplatinierung und Vernickelung metallener Gegenstände auf demselben Weg, Verlag Carl Friedrich Amelang, Berlin, 1843, 279