Electroplating is a cross-sectional technology of great importance for numerous industries, but it also involves special risks. Industrial insurance broker Funk, headquartered in Hamburg, works with hardware and software specialists to use the intelligent e.Guard sensor solution based on residual current analysis. This can detect anomalies and degradation in system operation at an early stage - and thus helps to prevent damage before it occurs.

Can sensors warn of safety risks before an accident occurs? Funk's e.Guard should make early detection possible

Electroplating and surface technology is one of the most important cross-sectional technologies across numerous industries and is responsible for the wear resistance, corrosion protection and optical properties of products. Depending on the type of operation, electroplating plants combine numerous ignition sources with high currents, a corrosive process atmosphere, flammable and/or toxic liquids and flammable system components. The list of possible risk factors is therefore long, and experience has shown that the number of process malfunctions and fire incidents around electroplating systems is high. Typical causes of fire include

- Drying out and subsequent overheating of baths with electric bath heaters or the start of direct bath heating with empty/unfilled baths due to a lack of fill level monitoring

- Electrical defects in system-related switching and control equipment or units such as pumps and motors

- Corrosion of connection contacts and electrical connections on the DC side

- Incorrectly aligned and unclean contact blocks

- Explosive atmospheres due to hydrogen formation

Necessary basis: effective concept

Fire incidents not only lead to high damage to property and business interruption, but also pose a particular risk to people and the environment. In order to minimize the probability and extent of such damage, the right fire protection is essential.

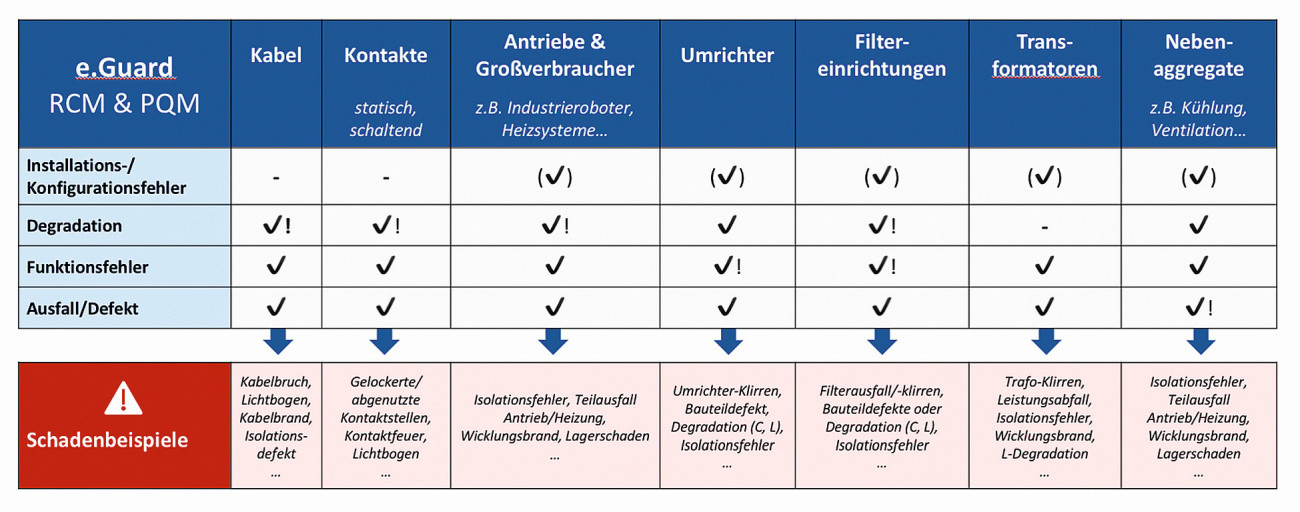

Fault types that can be monitored by the e.Guard system on various parts of the electrical infrastructure. Legend: ⎷ = prompt alerting and predictive warning; (⎷) = prompt alerting; ⎷! = particularly high relevance in customer dialog

Fault types that can be monitored by the e.Guard system on various parts of the electrical infrastructure. Legend: ⎷ = prompt alerting and predictive warning; (⎷) = prompt alerting; ⎷! = particularly high relevance in customer dialog

"A combination of close monitoring and automated shutdown of the electroplating systems is particularly effective here," explains Viktor Geracik, fire protection engineer at Funk. "However, many electroplating plants have a lot of catching up to do when it comes to the corresponding measures - be it the fire-resistant separation of production areas or the installation of fire detection and suppression systems." However, basic fire protection is essential in order to remain adequately insurable. Funk's fire protection engineers therefore also provide comprehensive support to electroplating companies in implementing suitable protection concepts.

Intelligent sensor monitoring from the control cabinet

Electroplating processes therefore have a particular risk potential on the one hand, but are also highly relevant for business value creation on the other. For this reason, companies in the industry are also looking for ways to monitor their systems automatically, proactively prevent damage and minimize downtimes in the interests of economic efficiency, beyond conventional fire protection. In the Beyond Insurance division, Funk is therefore offering an innovative solution for damage prevention in cooperation with technology partners: 'The industrial monitoring solution e.Guard from our partners Doepke (North) and twingz (Vienna) detects electrical anomalies and other risk-relevant status changes early and automatically - on systems with electrochemical processes and also on auxiliary units,' says Manuel Zimmermann, Business Development Manager at Funk and responsible for the Beyond Insurance division, in which the expertise relating to IIoT-based damage prevention is bundled.

Installation situations of the residual current monitors: on the left in the control cabinet and on the right in a separate industrial housing

For this purpose, sensors in the form of special residual current monitors are installed in the control cabinet at supply points of systems that are to be monitored. The sensors continuously record residual current data as the sum of residual currents and (possibly operational) leakage currents. This data is evaluated using artificial intelligence (AI) methods in the cloud and in near real time, where possible together with data that is often already available from power quality monitoring (PQM). "In contrast to conventional residual current monitoring, we don't just limit ourselves to simple threshold values relevant to fire protection. Instead, the system dynamically identifies anomalies, creeping degradation and typical risk conditions during operation, based on patterns from the earliest stages of development," says Zimmermann. These scenarios include, for example, insulation faults, contact corrosion or electric arcs, but also anomalies such as foreign objects in the bath or blocked exhaust air systems.

Damage prevention meets process optimization

In the event of relevant anomalies or deterioration in condition, the system notifies a defined group of people in the company via a browser-based dashboard, email or text message. Depending on how critical the scenario is, specific measures can be set up until automatic shutdown. After the training phase of the e.Guard system, this also includes condition-based, predictive maintenance recommendations, which operators can use to optimize maintenance costs and increase system availability. In addition, the system can replace recurring tests such as insulation resistance measurements.

Current practical example from a surface technology company

A current project example provides insights into the design, functionality and benefits of the e.Guard system: the user is a company specializing in the cleaning and coating of metallic surfaces by means of passivation, anodizing, chrome plating as well as galvanic nickel plating and zinc plating. Following its own experience of damage in the past, the company decided to additionally monitor a production site in terms of the electrical safety and reliability of the systems. Specifically, the internal and external anode lines as well as the transformers and rectifiers of the existing baths were placed under continuous monitoring by the e.Guard system. In addition to the bath systems, the heart of production, subsystems essential to the value creation process were also included in the monitoring - in particular the drives of the exhaust air systems.

Hardware, software and installation

Within the existing control cabinets, the relevant cable lines were retrofitted with smart residual current monitors of the Doepke DCTR model. The AC/DC-sensitive sensors continuously record the level of the current leakage and residual currents in the frequency range from 0 Hz (DC) to 100 kHz. Integration into the sensitive production network is not necessary; instead, networking takes place in secure stand-alone operation via an LTE gateway. This provides the communication interface between the sensors and the cloud-based e.Guard software, including AI-based analysis. A central network cabinet contains the entire network connection as well as the redundant cloud connection of 30 sensors for monitoring 30 load circuits.

The e.Guard reports an anomaly and issues an alarm on a bathroom system: foreign object has fallen into the bathroom, unwanted additional contact between the internal and external anode supply

The e.Guard reports an anomaly and issues an alarm on a bathroom system: foreign object has fallen into the bathroom, unwanted additional contact between the internal and external anode supply

Functions and benefits Using deep learning, the e.Guard system continuously analyzes the residual current data recorded in near real time in combination with PQM (process-oriented quality management) data for anomalies during actual electroplating operation. The system checks whether the anomalies correspond to risk-relevant operating patterns of the monitored systems. The so-called state estimator continuously assesses the current operating state in comparison to previous states - both across all frequency channels of each individual sensor and by aggregating all sensors for the entire covered part of the campus. In the case of the surface technology company, these were the bath systems including subsystems. After sufficient training, the intelligent software can now detect various changes as patterns at an early stage: both short-term anomalies such as electric arcs, foreign objects in the bath or poor contacting, as well as longer-term, creeping changes, e.g. insulation faults and contact surface corrosion.

Dynamic damage prevention thanks to validation and retraining

The e.Guard system is constantly learning: its stock of fault and degradation patterns, which is available on delivery and is individually adapted to the specific installation site during commissioning, is regularly expanded. This expansion occurs when an incident is recognized as an anomaly that has never occurred in this form before. In such a case, a validation loop was carried out in cooperation with the employees of the electroplating company and the operating pattern, which may be very customer-specific, was named. This then becomes part of the system's wealth of experience in the customer-specific application.

Manuel Zimmermann: "However, the measuring principle of the e.Guard solution is not just limited to electroplating bath systems. A large number of electrically operated industrial systems, especially those with frequency converters or inverters, can be equipped. In this way, we offer a scalable solution for monitoring production and storage that not only ensures greater safety, but also combines damage prevention and cost optimization."