Using a special roll-to-roll production process, the Fraunhofer FEP has developed a technology for the precise application of copper and aluminum layers to polymer films for the manufacture of current collectors. The conductivity and thickness of the layers are comparable to conventional current collectors based on metal foils. The new current collectors for lithium-ion batteries are lighter and less flammable than conventional ones.

It is hard to imagine our modern world without lithium-ion batteries. They enable us to use mobile devices such as smartphones, tablets and robot vacuum cleaners as well as electromobility. However, the many advantages such as high energy density, compact design and long service life are offset by a decisive disadvantage: Due to the properties of lithium (highly flammable and fast reacting), there is always a certain risk of fire. Overcharging, damage or overheating can lead to an uncontrolled release of the stored energy. This is called "thermal runaway".

Polymer films coated on both sides

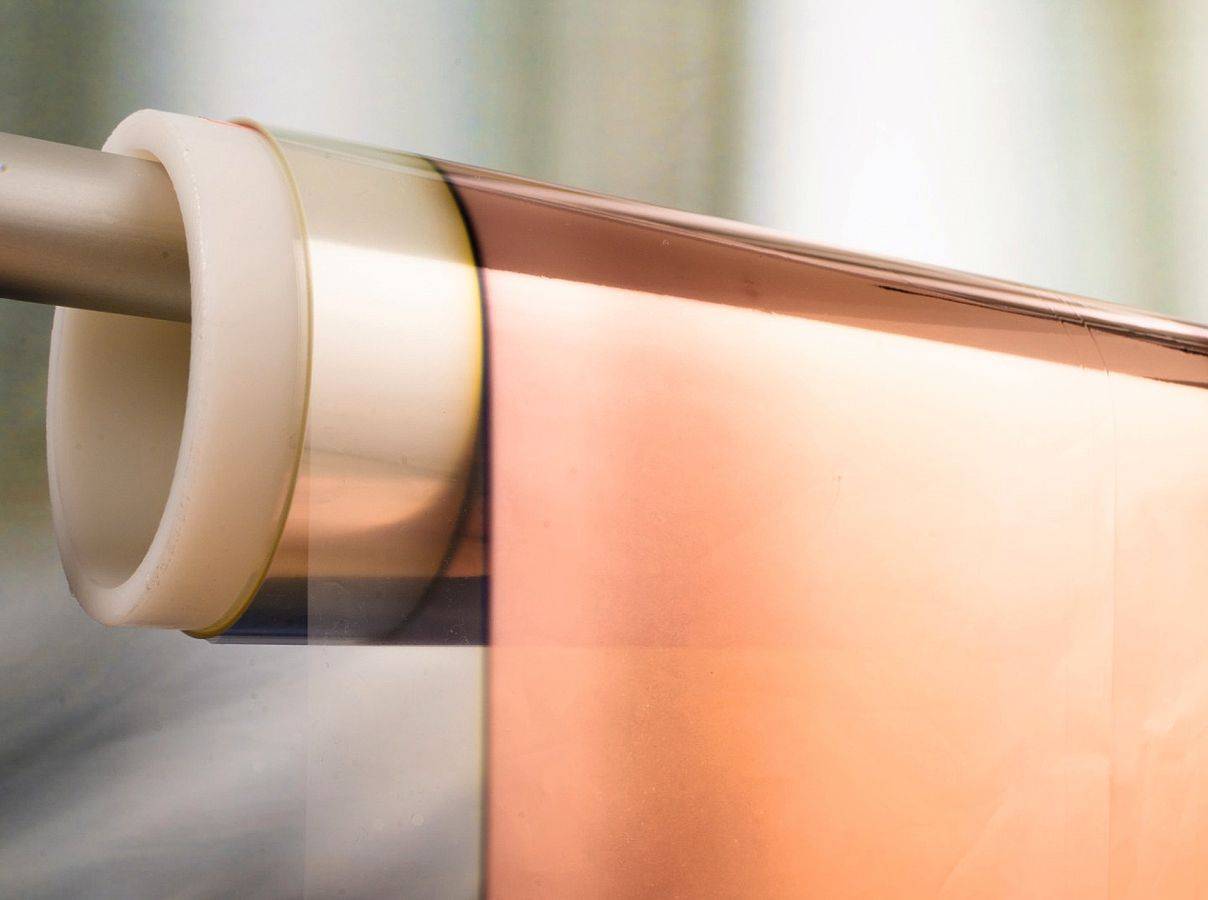

Plastic film coated with copper using electron beam evaporation for use as a metal-polymer current collector for battery cellsTheFraunhofer Institute for Electron Beam and Plasma Technology FEP is working on innovative solutions for vacuum coating and the treatment of surfaces, liquids and gases. The process developed makes it possible to replace conventional current collectors, usually metal foils, with so-called metal-on-polymer current collectors. These consist of polymer foils coated on both sides with a thin layer of aluminum or copper. These current collectors offer several advantages: they reduce the weight of the collector, which leads to a higher energy density of the cell. Even more important, however, is the safety aspect: should a short circuit occur in the cell, the polymer substrate melts and interrupts the current path. This prevents further heat build-up and thermal runaway.

Plastic film coated with copper using electron beam evaporation for use as a metal-polymer current collector for battery cellsTheFraunhofer Institute for Electron Beam and Plasma Technology FEP is working on innovative solutions for vacuum coating and the treatment of surfaces, liquids and gases. The process developed makes it possible to replace conventional current collectors, usually metal foils, with so-called metal-on-polymer current collectors. These consist of polymer foils coated on both sides with a thin layer of aluminum or copper. These current collectors offer several advantages: they reduce the weight of the collector, which leads to a higher energy density of the cell. Even more important, however, is the safety aspect: should a short circuit occur in the cell, the polymer substrate melts and interrupts the current path. This prevents further heat build-up and thermal runaway.

Coating by metal evaporation

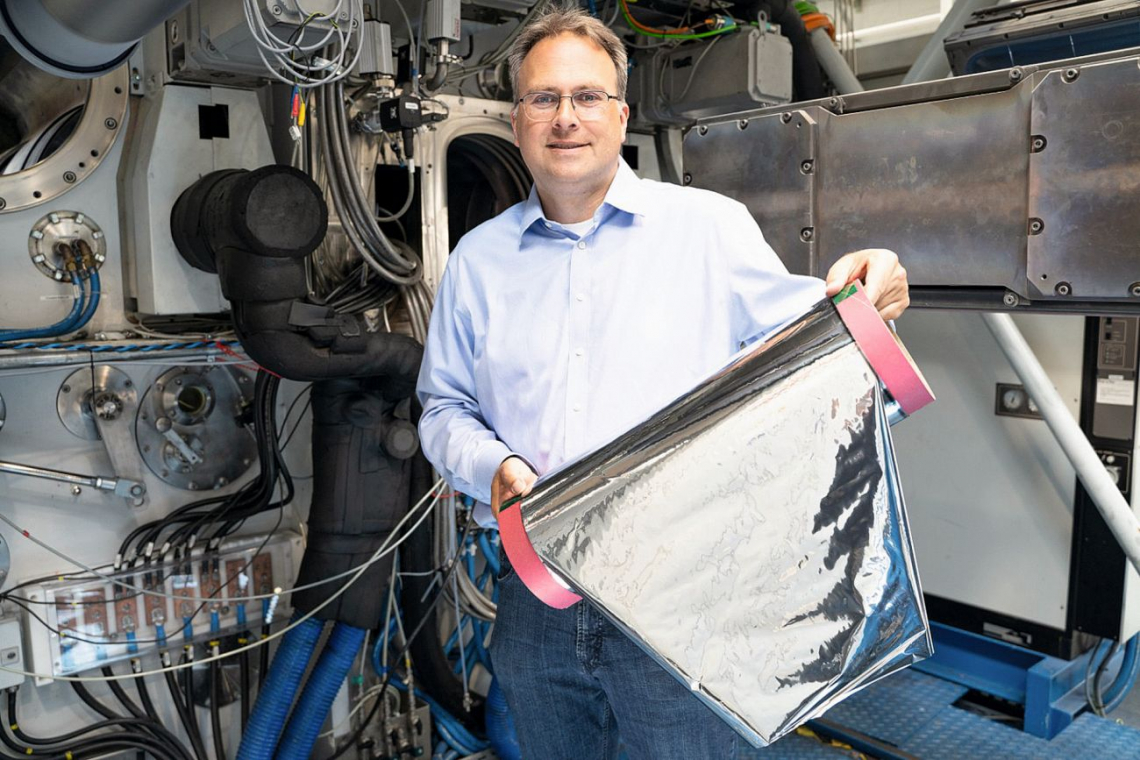

The process was developed as part of the PolySafe project funded by the German Federal Ministry of Education and Research (BMBF). The metal layers are applied to the polymer films by electron beam evaporation. Claus Luber, technical project manager, explains: "The challenge was to design the polymer films and the coating process in such a way that a thickness of the current collector comparable to current metal films and optimum electrical conductivity of the metal layer can be guaranteed." The aim was to gain a holistic understanding of the influence of the parameters of the belt run, substrate pre-treatment and metal evaporation and to develop optimum process settings to achieve the technological and economic requirements. Another challenge was to minimize the heat load during the deposition process, which was achieved by using a special cooling method - a gas cooling roller from Von Ardenne GmbH. This solution ensures high film quality and high productivity.

Results of the process development

The research team was able to successfully demonstrate the deposition of thick copper and aluminum layers on 12 µm thick PET films. The deposition was carried out in a roll-to-roll process on a roll width of up to 60 cm. The results include:

Copper:

Coated on both sides using a two-step process with copper layers up to 1 µm thick on each side;the copper layer appeared compact and the film remained

without significant wrinkling - ideal for further processing in battery production.

Aluminum:

Coating on both sides using a two-stage process with aluminum layers up to 1 µm thick on each side. Here too, the film was wrinkle-free, confirming its suitability for further processing for electrode coating.

Successful production of pouch cells

The metal-polymer current collectors produced using the new technology were successfully integrated into pouch cells by the project partner TU Braunschweig. These cells were tested for their electrochemical properties and compared with conventional reference cells. In these tests, the cells with the metal-polymer current collectors demonstrated similar performance and cycle stability to the reference cells at different charging and discharging rates.

Conclusion and outlook

With the new roll-to-roll process, metal-polymer collectors can be successfully produced using semi-industrial processes. The research results prove that these processes are suitable for producing current collectors that have the potential to increase the energy density of battery cells while minimizing safety risks. The new production process provides the industry with the basis for the further development of lithium-ion batteries with improved properties.

INFO

PolySafe project

Research project to increase the safety of lithium-ion batteries using metal-polymer composite current collectors

Funding body: Federal Ministry of Education and Research

Duration: 01.08.2021 - 30.04.2025

Project partner:

- Von Ardenne GmbH

- Brückner Maschinenbau GmbH & Co. KG

- Fraunhofer Institute for Electron Beam and Plasma Technology FEP

- Fraunhofer Institute for Surface Engineering and Thin Films IST

- Battery LabFactory Braunschweig (BLB) of the TU Braunschweig

- VARTA Microbattery GmbH