DeburringEXPO will be held from October 12 to 14, 2021 as an in-person event at Messe Karlsruhe. Precision surfaces you can touch.

The integrated specialist forum with simultaneously translated presentations (German <> English) also enables the important transfer of knowledge on current developments and trends in these manufacturing sectors.

The integrated specialist forum with simultaneously translated presentations (German <> English) also enables the important transfer of knowledge on current developments and trends in these manufacturing sectors.

Whether automotive and supplier industry, mechanical and plant engineering, medical and pharmaceutical technology, measurement, precision engineering and sensor technology, tool and mold making or energy and environmental technology - demand is booming again in many industrial sectors. However, component manufacturing is facing new and changing challenges due to transformation processes, changes in manufacturing technologies such as additive manufacturing, optimized and new materials, the trend towards automation and digitalization of production processes and regulatory requirements. As different as these may be in the various industries, burr-free and optimally machined surfaces for specific products are playing an increasingly important role. "On the one hand, the aim is to meet higher requirements in terms of quality, precision and energy efficiency when deburring and surface finishing. On the other hand, costs need to be reduced," says Hartmut Herdin, Managing Director of fairXperts GmbH & Co. KG and organizer of DeburringEXPO, describing some of the fields of action for companies.

As an information and communication platform clearly focused on deburring technologies and the production of precision surfaces, the leading trade fair enables a targeted and efficient comparison of technologies and services that is not possible at any other trade fair. This is also demonstrated by the fact that almost all market and technology leaders are represented at DeburringEXPO.

Cross-industry and cross-technology offering

The exhibitors' wide range of solutions is designed to efficiently meet current and future requirements. For manufacturers of medical technology products, one of the key issues is meeting the requirements of the new Medical Device Regulation (MDR), which has been mandatory since May 26, 2021. For sterile products, the MDR also considers particles for the first time. They can be caused by burrs, for example, which must therefore be removed reliably and traceably. In the automotive and supplier industry, the significant increase in demand for electric and hybrid vehicles is leading to an expansion in component production capacities. Burr-free surfaces and high-precision surface machining are required for numerous workpieces, including housings and rotor shafts. In the case of combustion engines, the primary focus is on further developments and optimization that can further reduce fuel consumption and emissions. The quality of the relevant surfaces plays just as important a role as burr-free precision machining, for example using ECM processes or laser technology. The increasingly stringent cleanliness requirements for precision parts, for example for measurement technology, the optical and sensor industry and production equipment for PCB manufacturing, also require reliable deburring. Similarly, the quality of subsequent processes such as joining, sealing, coating or assembly can only be ensured by burr-free and appropriately machined surfaces. These tasks will also be addressed at this year's leading trade fair in the "Cleaning after deburring" theme park.

The "AM Parts Finishing" theme park is dedicated to the post-processing of additively manufactured components. Solutions for removing support structures and residual powder, for smoothing and polishing surfaces and for preparing components for subsequent heat treatment or coating will be presented.

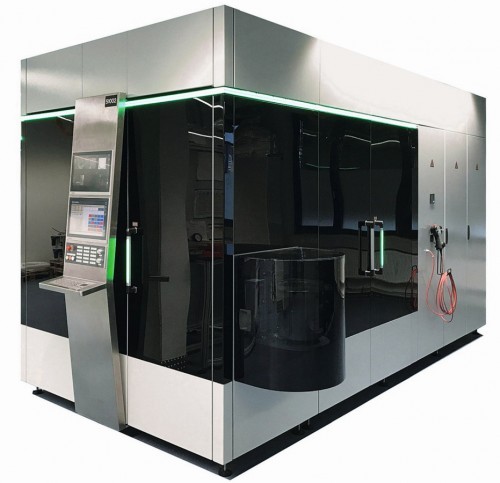

In order to produce faster, better and more economically, the automation and digitalization of deburring and surface finishing processes is becoming increasingly important across all industries. DeburringEXPO presents innovative and practical solutions for this with the theme park "Automated deburring with industrial robots". For example, a compact robot cell will be used to demonstrate all steps live, from component feeding, position detection, handling, burr detection by camera or sensor technology and the deburring process with integrated tool change to quality assurance and final storage of the component in product carriers.

Bilingual specialist forum - knowledge transfer as added value

The quality of the presentations and their high practical orientation ensure a valuable transfer of knowledge at the three-day specialist forum integrated into DeburringEXPO. Simultaneously translated (German <> English), the presentations provide information on basic principles, ways to optimize processes and costs, best-practice applications and trends as well as the content of the theme parks.

Image source: fairXperts, Image source: Stoba Sondermaschinen