Systems for electroplating components in a closed system are developed at the Lake Constance Surface Technology Institute in Buchheim. This so-called gram selective technology (GST) was also used to coat key components of the LHC particle accelerator around 40 years ago. GST technology is now in demand worldwide.

It is known as a world machine. Built with enormous technical effort and billions of euros from 23 countries, it is used to research elementary particles, the smallest components of matter. The aim is to gain new insights into the laws of nature. We are talking about the Large Hadron Collider (LHC) particle accelerator at the Cern research center in Geneva, a huge 30-kilometer-long tube construction that is surrounded by superconducting electromagnetic coils, among other things, to keep the particles on course with a strong magnetic field and keep them there. Due to its enormous dimensions, the particle accelerator is located on both Swiss and French territory.

Aluminum profiles that keep out interference radiation

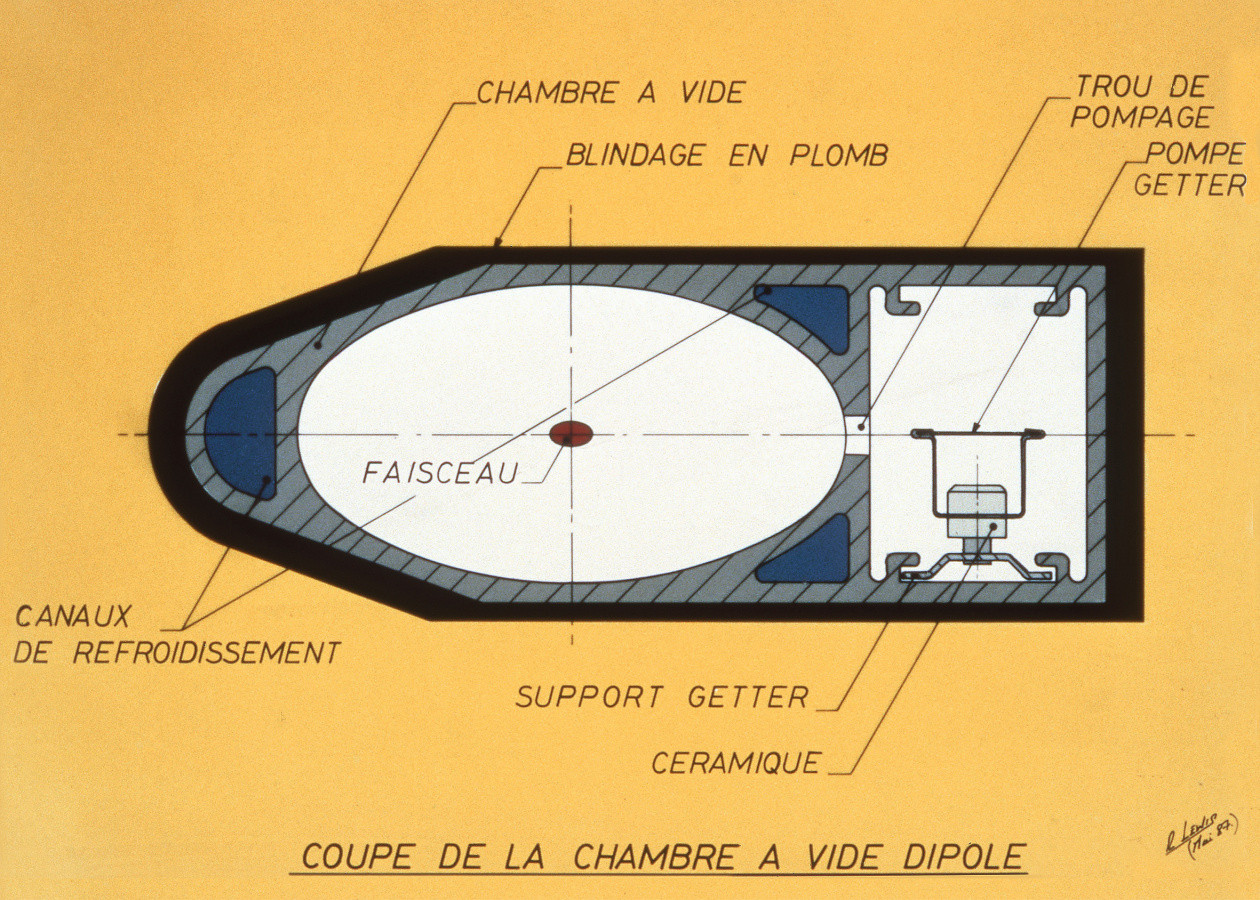

Lake Constance Surface Technology Institute in Buchheim. The focus of the research: the further development of GST technology and, in the long term, the production of small series The high-vacuum tube highway is made up of twelve-metre-long aluminum profiles that have been selectively coated with nickel and tin. They also have a lead coating to prevent interference radiation. This is because the facility uses huge amounts of energy to accelerate particles almost to the speed of light and then cause them to collide. What happens during this collision is the subject of research and must be measured without interference - with the help of the coated aluminum profiles. Electroplating technology is therefore an indispensable technological building block for clarifying essential questions of our existence and, if necessary, for further developing technologies. The research objectives of the particle accelerator include investigating the Higgs boson particle, the last particle of the standard model of particle physics that has not yet been detected, as well as tracking down possibly undiscovered spatial dimensions. At times, there was public concern that the accelerator could create black holes and thus endanger the existence of the earth.

Lake Constance Surface Technology Institute in Buchheim. The focus of the research: the further development of GST technology and, in the long term, the production of small series The high-vacuum tube highway is made up of twelve-metre-long aluminum profiles that have been selectively coated with nickel and tin. They also have a lead coating to prevent interference radiation. This is because the facility uses huge amounts of energy to accelerate particles almost to the speed of light and then cause them to collide. What happens during this collision is the subject of research and must be measured without interference - with the help of the coated aluminum profiles. Electroplating technology is therefore an indispensable technological building block for clarifying essential questions of our existence and, if necessary, for further developing technologies. The research objectives of the particle accelerator include investigating the Higgs boson particle, the last particle of the standard model of particle physics that has not yet been detected, as well as tracking down possibly undiscovered spatial dimensions. At times, there was public concern that the accelerator could create black holes and thus endanger the existence of the earth.

Coating and soldering in the lead plant

A modern electroplating process was used for the coating process: GST technology from Gramm Technik GmbH in Ditzingen. "The entrances and exits of the aluminum profiles were masked with our GST technology. We first coated the main surfaces with a nickel layer and later with a tin layer," says Gerhard Gramm, Managing Director of Gramm Technik GmbH, recalling the coating phase of the profiles in the run-up to the commissioning of the world machine in 2008. "Tin because the whole thing was later soldered with lead plates," he adds. The 85-year-old is sitting at a large conference table at his company's development center, the Oberflächentechnisches Institut Bodensee (OIB) in Buchheim, while he talks about the project. Through the wide glass window behind him, a corner of Lake Constance can be glimpsed in the distance beyond the rolling green fields.

Sketch of the particle accelerator with integrated high-vacuum chamber

Sketch of the particle accelerator with integrated high-vacuum chamber

In addition to many other research activities, GST technology is constantly being further developed here in the far south of Germany. It reverses conventional electroplating technology: the component is not coated in chemical baths, instead the chemistry is applied to the component. Introduced in 1980, the technology is now used successfully all over the world. Various process media can be used in a coating cell in which negative pressure prevails. The component can be cleaned, rinsed, pickled and coated there, depending on the requirements. The advantages are low emissions and waste water as well as integration into the production line. The technology is suitable for series production, but cannot be used as flexibly as open electroplating baths in contract electroplating shops, for example.

"We implemented the Cern project in a lead plant in Goslar," continues Gerhard Gramm. "We had enough space there. There was an anodizing plant next door, which was closed but owned by the lead works," the entrepreneur recalls. The profiles were then coated as required using the GST system set up in the factory and then soldered in the neighboring lead works.

Cross-section of the 12-metre-long aluminium vacuum chambers, which were electroplated with a nickel-tin coating

Cross-section of the 12-metre-long aluminium vacuum chambers, which were electroplated with a nickel-tin coating

OIB workforce to increase

GST linear system at OIBThecoated aluminum profiles for the particle accelerator had long since been delivered and installed when the OIB research center opened in 2014. Today, nine scientists work here. Together with the extension added in 2020, 15-20 employees will be working in Buchheim in the near future. Their task is to develop GST systems for numerous processes - from anodizing and coating with precious metals or the patented CERAMductile® material to hard chrome, nickel, tin, zinc, gold and silver, etc. The machines are also of interest for technical cleaning and pickling of components. Once the development of the system technology for a component has been completed in Buchheim, the order is usually carried out in the plants in Ditzingen, Ilmenau or Poland.

GST linear system at OIBThecoated aluminum profiles for the particle accelerator had long since been delivered and installed when the OIB research center opened in 2014. Today, nine scientists work here. Together with the extension added in 2020, 15-20 employees will be working in Buchheim in the near future. Their task is to develop GST systems for numerous processes - from anodizing and coating with precious metals or the patented CERAMductile® material to hard chrome, nickel, tin, zinc, gold and silver, etc. The machines are also of interest for technical cleaning and pickling of components. Once the development of the system technology for a component has been completed in Buchheim, the order is usually carried out in the plants in Ditzingen, Ilmenau or Poland.

In the OIB laboratory in Buchheim, there are numerous systems in which process cells can be seen behind glass. The components are placed in tightly sealed reactors, which are usually adapted to the substrate, explains Gerhard Gramm. Both the deposition electrolyte and all other chemicals for coating as well as pre- and post-treatment are located in closed tanks and are pumped into the process chamber under computer control. This saves on process solutions and also increases process reliability thanks to the repeat accuracy. The parts enter the GST system in baskets, he explains. Another advantage of the systems is that they require less space than electroplating baths.

In addition to the further development of GST technology, Gramm Technik also wants to get more involved in the fields of medical and watch technology with the help of the research facility. To this end, additional employees are to be hired in Buchheim to produce small series. The proximity to the "medical technology capital" of Tuttlingen should help to expand the business in this area, as will the experience gained in the past. After all, Gramm Technik was already active in this profitable sector: The thriving dental technology business, more specifically electroformed dental prostheses made of gold, was sold off just two years ago. The reason: global sales and the associated consulting no longer fitted Gramm Technik's business model. However, GST devices continue to be supplied to the former partner and current owner of the former division, Heimerle + Meule GmbH in Pforzheim. According to Gerhard Gramm, around 5000 systems for the production of dentures are in use worldwide.

Wide range of applications

Employees at the so-called GST tableThe field of applicationof GST systems is, for example, the hard anodizing of engine pistons. Every year, 170 million pistons are now fully coated using this technology. One such piston can be seen on a shelf with product examples in the OIB, which Gerhard Gramm is visibly proud to hold in his hands. Hard anodizing requires very high currents and cooling of the electrolyte so that it does not overheat. However, GST coating with nickel and tin is also used for busbars, from which the electricity is drawn in buildings before it reaches the sockets. Partial coating is also possible with the system technology, for example on modern braking systems for conventional and electric vehicles. "This braking system is partially coated with an oxide layer in three places," Gerhard Gramm demonstrates on a complex metal component in which small valves are integrated. Two Gramm systems for this purpose are in service in the USA. Numerous other GST machines are in use in automotive engineering, household and electrical engineering and heating technology.

Employees at the so-called GST tableThe field of applicationof GST systems is, for example, the hard anodizing of engine pistons. Every year, 170 million pistons are now fully coated using this technology. One such piston can be seen on a shelf with product examples in the OIB, which Gerhard Gramm is visibly proud to hold in his hands. Hard anodizing requires very high currents and cooling of the electrolyte so that it does not overheat. However, GST coating with nickel and tin is also used for busbars, from which the electricity is drawn in buildings before it reaches the sockets. Partial coating is also possible with the system technology, for example on modern braking systems for conventional and electric vehicles. "This braking system is partially coated with an oxide layer in three places," Gerhard Gramm demonstrates on a complex metal component in which small valves are integrated. Two Gramm systems for this purpose are in service in the USA. Numerous other GST machines are in use in automotive engineering, household and electrical engineering and heating technology.

Two systems for the hard chrome plating of valves and piston rods are currently under construction. "They are hard chrome plated in a closed system without waste water containing chromium and exhaust air," emphasizes the entrepreneur. "This happens ten times faster than in a normal open system," he says, promoting his technology.

INFO

Gramm Technik GmbH

Number of employees: between 230-250

Business areas: Plant engineering and contract electroplating for aluminium substrates

Locations: 8 in total - Ditzingen, Ilmenau, Illingen/Saar, Buchheim; Poland, USA, Mexico, China.

From a craft business to a small global player

A Gramm employee in the physics laboratory in BuchheimGerhardGramm has now reached an advanced age of 85. He originally took over the company - at that time still a small craft business founded in 1930 - from his father. Before that, he completed a commercial apprenticeship, attended the electroplating college in Solingen and gained experience in an industry company. His expertise was soon in demand and he lectured in Aachen, where his wife is from, while managing the company. When plastic electroplating became fashionable in the industry in the 1970s, Gramm Technik moved into aluminium coating and subsequently developed the company to its current size with branches in several regions of the world. Today, business is going well, partly due to the broad customer base. When the automotive industry weakened in 2009, for example, demand for medical technology increased. This gave rise to the idea of setting up the research center in Buchheim near Tuttlingen. Even if the entrepreneur Gerhard Gramm cannot really let go yet. His successor at Gramm Technik is already in place: Peter Schilderoth is already Managing Director at his side. A Technical Managing Director is to be added in 2023. A son and a daughter also work at the company. There could also be a successor to the flagship project for the particle accelerator in Geneva. So things remain exciting at Gramm. Who knows to what extent Galvanotechnik can continue to support the further development of the world machine - after all, the scope of the particle accelerator is even to be extended to 100 kilometers one day.

A Gramm employee in the physics laboratory in BuchheimGerhardGramm has now reached an advanced age of 85. He originally took over the company - at that time still a small craft business founded in 1930 - from his father. Before that, he completed a commercial apprenticeship, attended the electroplating college in Solingen and gained experience in an industry company. His expertise was soon in demand and he lectured in Aachen, where his wife is from, while managing the company. When plastic electroplating became fashionable in the industry in the 1970s, Gramm Technik moved into aluminium coating and subsequently developed the company to its current size with branches in several regions of the world. Today, business is going well, partly due to the broad customer base. When the automotive industry weakened in 2009, for example, demand for medical technology increased. This gave rise to the idea of setting up the research center in Buchheim near Tuttlingen. Even if the entrepreneur Gerhard Gramm cannot really let go yet. His successor at Gramm Technik is already in place: Peter Schilderoth is already Managing Director at his side. A Technical Managing Director is to be added in 2023. A son and a daughter also work at the company. There could also be a successor to the flagship project for the particle accelerator in Geneva. So things remain exciting at Gramm. Who knows to what extent Galvanotechnik can continue to support the further development of the world machine - after all, the scope of the particle accelerator is even to be extended to 100 kilometers one day.