Are we facing a difficult winter?

Our thoughts in the coming winter should be with us, our companies and also with the brave people in Ukraine. Last February, when Vladimir Putin began his so-called "Special Military Operations", we soon realized that his goal was - quite simply - to conquer the country militarily. But in recent weeks, that seems to have changed. Now Putin seems to realize that he will not be able to conquer Ukraine, now he apparently just wants to destroy it. He is not targeting military facilities with missiles and "kamikaze drones", but power stations, power lines, waterworks, schools, residential buildings, etc. With missiles and drones launched hundreds of kilometers away, his soldiers are not exposed to any danger. An Iranian Shahed 136 kamikaze drone costs perhaps 20,000 euros. It carries a warhead of up to 50 kg of explosives and Russia has apparently bought or ordered around 3000 units. However, the Ukrainian military appears to shoot down at least 50%, and in some cases up to 80%, of incoming drones, which travel at 180 km/h. The drones are controlled by GPS (Global Positioning Satellite) - the Ukrainian military is learning to jam this signal.

Winter is approaching

Military experts are well aware that winter slows down military operations - in some cases even brings them to a standstill. This is reportedly already the case in Ukraine. They also know that in winter, the "home team" - in this case Ukraine - has the advantage. They have also not forgotten that two of the greatest military defeats in history took place not far from where the battles are being fought today. Napoleon's greatest defeat was his disastrous retreat from Moscow in 1812, in which his army was reduced from around 600,000 men to around 100,000. Half a million French soldiers died or were taken prisoner. Figure 1 is a depiction of Napoleon's disastrous retreat (we can be sure that the painter was thousands of miles away and only using his imagination). History repeated itself in 1941/1942 when Nazi Germany failed to capture Moscow as part of "Operation Barbarossa". Perhaps a million German and Russian soldiers died in this failed operation. History is repeating itself today in that - just as with the German soldiers in 1941/1942 - there are many reports of Russian soldiers lacking winter clothing.

Energy future

Fig. 2: A floating natural gas storage regasification unit (FSRU) in Klaipeda (Lithuania)We still don't know who caused the massive damage to the Nordstream pipelines and what they hoped to achieve. Europe is currently massively expanding its ability to import liquefied natural gas (LNG) from the Middle East and the USA. Germany and the UK are among the countries building new LNG terminals or reopening those that were previously closed. At the end of October, over 60 large LNG tankers were waiting near the European LNG terminals to unload their gas cargoes. Like all commercial ships, these tankers automatically transmit their location. At the LNG terminals, the liquefied natural gas is heated to room temperature so that it can be fed into the natural gas network. In some cases, this is done at onshore facilities. However, the fastest way to expand capacity is to use ships moored in a port to do this. These are known as FSRUs (Floating Storage Regasification Units). Figure 2 shows an FSRU in Klaipeda, Lithuania. A fifth German FSRU in Wilhelmshaven is almost complete and another is still in the planning stage. Sooner or later, the war in Ukraine will end. But by then we will have established a new natural gas supply chain in Europe based on LNG imports, and I don't think we will ever go back to importing Russian natural gas. Will the Russians find other customers for their natural gas? Almost certainly - yes. But because their new customers in Asia and China are less affluent and because there will be no more competition from Europe, the price of Russian natural gas is likely to be lower than in the past. The war will cause great and lasting damage to the Russian economy. If we get our energy supply under control for the coming winter, we should be more or less back to normal next winter and Russian gas imports will be history.

Fig. 2: A floating natural gas storage regasification unit (FSRU) in Klaipeda (Lithuania)We still don't know who caused the massive damage to the Nordstream pipelines and what they hoped to achieve. Europe is currently massively expanding its ability to import liquefied natural gas (LNG) from the Middle East and the USA. Germany and the UK are among the countries building new LNG terminals or reopening those that were previously closed. At the end of October, over 60 large LNG tankers were waiting near the European LNG terminals to unload their gas cargoes. Like all commercial ships, these tankers automatically transmit their location. At the LNG terminals, the liquefied natural gas is heated to room temperature so that it can be fed into the natural gas network. In some cases, this is done at onshore facilities. However, the fastest way to expand capacity is to use ships moored in a port to do this. These are known as FSRUs (Floating Storage Regasification Units). Figure 2 shows an FSRU in Klaipeda, Lithuania. A fifth German FSRU in Wilhelmshaven is almost complete and another is still in the planning stage. Sooner or later, the war in Ukraine will end. But by then we will have established a new natural gas supply chain in Europe based on LNG imports, and I don't think we will ever go back to importing Russian natural gas. Will the Russians find other customers for their natural gas? Almost certainly - yes. But because their new customers in Asia and China are less affluent and because there will be no more competition from Europe, the price of Russian natural gas is likely to be lower than in the past. The war will cause great and lasting damage to the Russian economy. If we get our energy supply under control for the coming winter, we should be more or less back to normal next winter and Russian gas imports will be history.

A new material

Most of us are familiar with plasticine, which is mainly used by children. There is "plasticine" and, more recently, "play-doh" (doh = dough). These materials behave like plasticine in many respects, but they are not watery and not electrically conductive. Now a new modeling material has been developed that is electrically conductive.

The molecular structure of the material, discovered by researchers at the University of Chicago, is jumbled and disordered, suggesting that it is a poor conductor. Good conductors generally consist of straight, tightly packed rows of atoms or molecules, allowing electrons to flow easily through the material. A conductive material without these properties calls into question a fundamental principle of conductivity and could represent a paradigm shift in materials science.

The new material is an amorphous coordination polymer, NiTetrathiafulvalene tetrathiolate, which exhibits extremely high electronic conductivity (up to 1,200 S cm-1) and intrinsic glassy-metallic behavior. Theory shows that these properties are enabled by a molecular overlap that is robust to structural perturbations. This unusual combination of features results in a high conductivity that is stable for weeks in humid air, at pH 0-14 and at temperatures up to 140 °C. These results show that molecular design can enable metallic conductivity even in highly disordered materials. The new material forces scientists to rethink the whole concept of electrical conductivity, while on the practical side it is not difficult to imagine many new applications for such materials.

Source: Intrinsic glassy-metallic transport in an amorphous coordination polymer - Jiaze Xie, et al. Nature (2022) Vol 4956 (Oct) https://doi.org/10.1038/s41586-022-05261-4

Further progress in green energy

I am always happy to report on new developments in the field of "green energy". Wind turbines are either on land or at sea. Until recently, offshore wind turbines, which are anchored to the seabed, could only be installed in relatively shallow waters. The new Scottish wind farm "SeaGreen" now holds a new record. The approximately 1 GW wind farm with 10 MW turbines from Vestas is located 27 km off the Scottish coast at a water depth of 59 m - a world record. The wind farm has started supplying electricity and will be fully operational in a few months. And the wind turbines are slowly getting bigger and bigger. The Spanish-German wind power giant Siemens Gamesa has received an order for 60 of its SG 14-222 DD offshore wind turbines to be installed at the 882 MW Moray West offshore wind farm in Scotland. This is the first installation of the world's most powerful wind turbine with a capacity of 14.7 megawatts (MW). Each SG 14-222 DD offshore wind turbine will have a rotor diameter of 222 meters. But it is likely that Siemens Gamesa's 14.7 MW turbines will not remain the most powerful turbines for long. In February 2021, Danish wind turbine manufacturer Vestas announced the market launch of its new V236-15.0MW offshore wind turbine. In June, Vestas announced that the company is expected to receive an order for the supply of 64 V235-15.0MW wind turbines for EnBW's 900MW He Dreiht offshore wind farm in Germany in 2025.

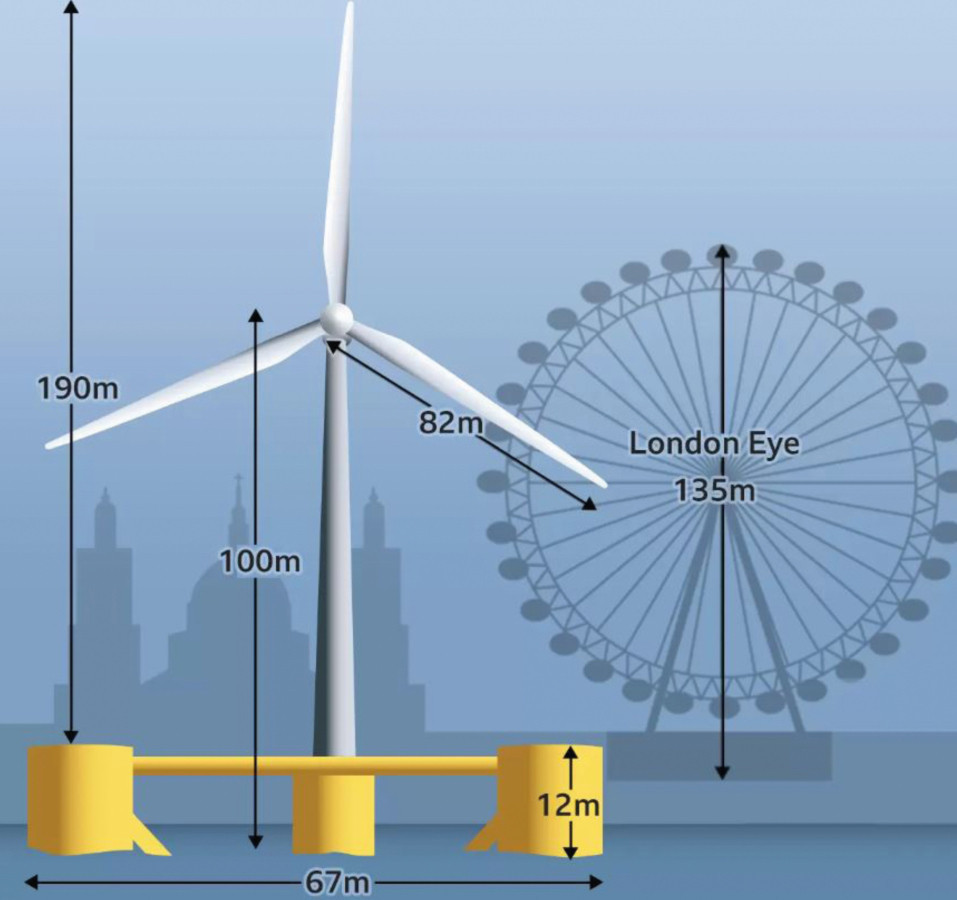

Fig. 3: A floating wind turbine in Kincardine, Scotland

Fig. 3: A floating wind turbine in Kincardine, Scotland

Nevertheless, it is clear that such fixed offshore turbines will not be sufficient to meet future demand - the only solution is floating wind turbines. One such project is WindFloat Atlantic, which is located 20 km off the coast of Viana do Castelo, Portugal, and generates 25 MW. Another turbine of this type is now in operation in Kincardine off the Scottish coast (Fig. 3).

Each tower sits on three huge cylindrical floats. They are painted bright yellow and welded together to form a triangular platform, each side of which is 67 m long. The system is not "passive" - the floats have to adapt to changes in wind and sea conditions. A network of pumps and valves shifts liquid ballast between the three floating cylinders to rebalance the platform and adjust the turbine to the ideal angle for the wind. Below the surface, weighted underwater cables attached to giant anchors ensure that the platform is firmly anchored to the seabed. And for the future? Around two thirds of the offshore wind potential in the US is thought to be in deep waters, 80% of the European seabed is only accessible by floating technology, and much of the sea off Japan is also deep. According to RenewableUK, the total global pipeline of floating wind power projects has doubled in the last year alone and now totals 180 GW. According to calculations by the Offshore Renewable Energy Catapult, a British research center for offshore wind technology, floating wind energy will represent a global market of 400-5000 billion euros by 2050. The big challenge now is the cost. This new technology is expensive. Kilowatt hour for kilowatt hour, floating wind power costs about as much as new nuclear power - around 90-100 euros/MWh.

Progress in nuclear power - the dream of fusion is getting closer

Fig. 4: Interior view of the Tokamak ST40 fusion reactorTokamakEnergy has unveiled plans for its latest prototype fusion reactor, claiming that nuclear fusion is only a decade away. According to the Oxford-based company, the ST80-HTS will be the world's first spherical high-field tokamak to use superconducting high-temperature magnets (HTS). The new reactor, due for completion in 2026, is the company's latest step towards commercial fusion power and will form the basis for the design of the ST-E1 fusion pilot plant, which is expected to deliver up to 200MW of net fusion power in the early 2030s. According to Tokamak Energy, the ST80-HTS is expected to deliver a higher triple product than any previous fusion plant. The triple product (nTττE) is a widely recognized measure of progress towards commercial fusion and combines measurements of plasma density, temperature and confinement. A dense plasma ensures better chances for particle collisions, a high temperature plasma enables fusion reactions, while a longer confinement time provides a larger window for sustained reactions. Tokamak Energy has already achieved plasma temperatures of over 100 million degrees with its spherical Tokamak ST40. The ST80-HTS will attempt to reach these temperatures, but the pulse duration will be significantly extended to achieve pulses of up to 15 minutes. Combined with sufficient plasma density, this should result in a triple product that comes close to the requirements of a commercial fusion power plant. Tokamak Energy reported that its ST40 spherical tokamak achieved a triple product of 6×1018 keV.s.m-3. This result was achieved earlier this year at a plasma temperature of 100 million degrees, the threshold required for commercial fusion power, in a spherical tokamak with a plasma volume of less than one cubic meter; this is 15 times less volume than any other tokamak that has reached this temperature.

Fig. 4: Interior view of the Tokamak ST40 fusion reactorTokamakEnergy has unveiled plans for its latest prototype fusion reactor, claiming that nuclear fusion is only a decade away. According to the Oxford-based company, the ST80-HTS will be the world's first spherical high-field tokamak to use superconducting high-temperature magnets (HTS). The new reactor, due for completion in 2026, is the company's latest step towards commercial fusion power and will form the basis for the design of the ST-E1 fusion pilot plant, which is expected to deliver up to 200MW of net fusion power in the early 2030s. According to Tokamak Energy, the ST80-HTS is expected to deliver a higher triple product than any previous fusion plant. The triple product (nTττE) is a widely recognized measure of progress towards commercial fusion and combines measurements of plasma density, temperature and confinement. A dense plasma ensures better chances for particle collisions, a high temperature plasma enables fusion reactions, while a longer confinement time provides a larger window for sustained reactions. Tokamak Energy has already achieved plasma temperatures of over 100 million degrees with its spherical Tokamak ST40. The ST80-HTS will attempt to reach these temperatures, but the pulse duration will be significantly extended to achieve pulses of up to 15 minutes. Combined with sufficient plasma density, this should result in a triple product that comes close to the requirements of a commercial fusion power plant. Tokamak Energy reported that its ST40 spherical tokamak achieved a triple product of 6×1018 keV.s.m-3. This result was achieved earlier this year at a plasma temperature of 100 million degrees, the threshold required for commercial fusion power, in a spherical tokamak with a plasma volume of less than one cubic meter; this is 15 times less volume than any other tokamak that has reached this temperature.

The triple product achieved is the highest ever achieved by a private fusion energy company. It is a widely recognized measure in the fusion industry for plasma density, temperature and confinement, which together provide a key measure of progress towards achieving commercial fusion conditions. Chris Kelsall, CEO of Tokamak Energy, said: "High performance in smaller spherical tokamaks is the key to commercial fusion power. Our latest achievement is further evidence of this optimal pathway to clean, safe, cost-effective, scalable and globally deployable commercial fusion power. We are proud to have achieved this result in collaboration with Princeton and Oak Ridge National Laboratories."

The ST40 spherical tokamak (Fig. 4) is currently being upgraded to develop further operational experience and efficient technologies for future devices, which the company will announce shortly.

A silent revolution?

Electric bikes have been around for some time, but they are expensive. Now we're seeing a revolution, with conversion kits that can be fitted to almost any bike and cost just 500 euros, maybe even less. I'll name just one, but I'm sure there are others that are just as good. The Swytch conversion kit consists of a new front wheel with a 250W electric motor on the hub and a handlebar-mounted battery pack (Fig. 5). The range is around 30 km. Germany leads the world with an estimated 2.1 million e-bikes, but most of them were bought as e-bikes and not converted from pedal bikes. Swytch claims that almost any bike (including folding models) can be converted at home in about 15 minutes. Will Germany quickly reach the 3 million mark?

Fig. 5: The Swytch kit turns any bike into an e-bike

Fig. 5: The Swytch kit turns any bike into an e-bike

Diamonds are good business

Fig. 6: The Opsydia laser device makes it possible to write inside a diamond Diamonds are good business - and unfortunately, although not surprisingly, criminals are also involved. In the Congo, criminal gangs are forcing children to work in diamond mines for low pay and in highly dangerous conditions. On the other hand, the technology for producing artificial diamonds is constantly being improved so that ever larger and better diamonds can be produced at ever lower costs. Artificial diamonds cost less than "real" diamonds - and criminals are tempting customers to buy artificial diamonds, mistaking them for "real" diamonds. The diamond industry has been trying to solve this problem for many years with "certificates of origin" and other means. But the criminals are clever. Now a new technology may offer a solution. A new company, Opsydia Ltd, based in Oxford, UK, has developed a laser-based technology that can describe the inside of a diamond. Its devices are the only ones on the market that can penetrate the surface of a diamond and manipulate its atoms to form an identity marker. Figure 6 shows one of the new machines.

Fig. 6: The Opsydia laser device makes it possible to write inside a diamond Diamonds are good business - and unfortunately, although not surprisingly, criminals are also involved. In the Congo, criminal gangs are forcing children to work in diamond mines for low pay and in highly dangerous conditions. On the other hand, the technology for producing artificial diamonds is constantly being improved so that ever larger and better diamonds can be produced at ever lower costs. Artificial diamonds cost less than "real" diamonds - and criminals are tempting customers to buy artificial diamonds, mistaking them for "real" diamonds. The diamond industry has been trying to solve this problem for many years with "certificates of origin" and other means. But the criminals are clever. Now a new technology may offer a solution. A new company, Opsydia Ltd, based in Oxford, UK, has developed a laser-based technology that can describe the inside of a diamond. Its devices are the only ones on the market that can penetrate the surface of a diamond and manipulate its atoms to form an identity marker. Figure 6 shows one of the new machines.

During a trial run for the BBC, the machine created the BBC logo approximately 0.5mm in size in a diamond. The laser can make changes at an atomic level to create electronic circuits inside the diamond. This could be useful for making radiation detection instruments, where the durability of the diamond is also an advantage. Potentially, such circuits could also be used in quantum computers, which are seen as the next big breakthrough in computer technology. Diamonds have unique electronic properties.

Green concrete?

A magnesium-based cement made with seawater could absorb carbon instead of expelling it like conventional cement. Although its properties make it unsuitable for reinforced concrete, the "carbon-negative" cement could be used in non-reinforced materials, including concrete blocks, which account for about 15% of all concrete applications. Billions of tons of Portland cement are produced each year, accounting for about 8% of global carbon dioxide emissions, from heating carbonaceous limestone with fossil fuels to produce calcium oxide. In the face of climate change, efforts to find more sustainable alternatives are urgently needed.

Reactive magnesium oxide cements are one such low-carbon alternative, especially as they solidify by absorbing carbon dioxide. However, such cements are usually extracted from the carbonaceous mineral magnesite, which is not available everywhere and releases CO2 during calcination to extract magnesium oxide.

Now, Dr. Shiho Kawashima and Dr. Daniel Esposito, who work at Columbia University in New York, have combined their respective expertise in cement processing and electrochemistry to develop a magnesium cement that uses magnesium hydroxide extracted from seawater instead of magnesium oxide. This eliminates the need for a carbon-releasing calcination step and could potentially remove more carbon than is released during production.

The process relies on membraneless electrolyzers developed by Esposito's lab, which generate an acidic and an alkaline current when seawater is passed through them. This allows precise control of the pH so that magnesium hydroxide can be precipitated. The team showed how this can be used to produce a cement that absorbs carbon dioxide during the curing process and forms solid carbonates that gain strength over time.

"Seawater is a carbon-free raw material, and in conjunction with carbonate curing, it is possible to achieve carbon negativity if the electrochemical harvesting process is powered by renewable energy and the carbon dioxide is sourced from the atmosphere through direct air capture or from the ocean through direct ocean capture technologies," explains Kawashima. However, there are also doubts about the feasibility of the new development.

P Batjatya et al. Proc. Nat, Acad. Sci. USA (2022) vol 119 e2114680119 DOI 10.1073/pnas2114680119