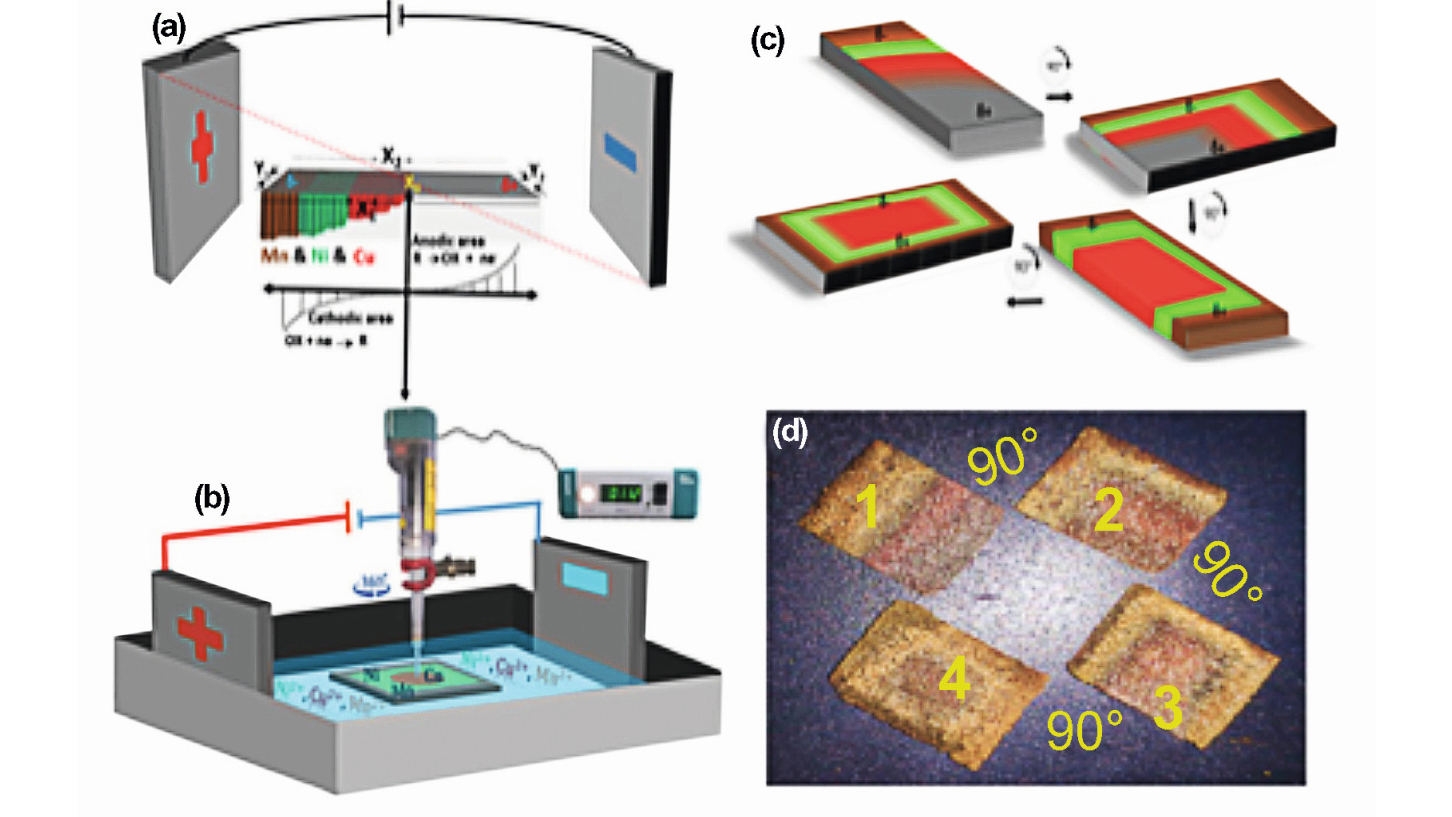

Persian carpets have been around for at least 2500 years and are world famous. Interestingly, scientists at Razi University in Kermanshah, Iran, have now described a scientific process in which concentric, multi-element metal carpets are fabricated by what is known as one-pot electroplating. A floating piece of nickel foam as a bipolar electrode (BPE) is rotated in an aqueous solution containing a ternary mixture of metal ions. A sufficient direct current potential is applied to the drive electrodes. The parameters potential gradient, rotation and concentration/kinetic polarization are varied to achieve the desired result. The generation of the radial multi-element gradient was tested in a "one-pot" electroplating process for art jewelry (Fig. 1).

Fig. 2: One-pot carpet-like bipolar electrotechnique that could be used in future jewelry piecesByadjusting the bipolar gradient potential as a function of the applied DC potential, the rotation speed of the BPE, the inherent kinetic polarization of the metal ions (standard reduction potentials) and the concentration polarization (concentration of the base materials), a combined gradient potential was generated that is captured by the rotated BPE. This results in a concentric, isolated alloy across the center to the edges of the BPEs. In an artistic one-pot electro-engineering of two typical ternary mixtures of Cu-Ni-Mn and Cu-Co-Mn on nickel foam (NF) as a bipolar electrode, a typical example was described (Fig. 2).

Fig. 2: One-pot carpet-like bipolar electrotechnique that could be used in future jewelry piecesByadjusting the bipolar gradient potential as a function of the applied DC potential, the rotation speed of the BPE, the inherent kinetic polarization of the metal ions (standard reduction potentials) and the concentration polarization (concentration of the base materials), a combined gradient potential was generated that is captured by the rotated BPE. This results in a concentric, isolated alloy across the center to the edges of the BPEs. In an artistic one-pot electro-engineering of two typical ternary mixtures of Cu-Ni-Mn and Cu-Co-Mn on nickel foam (NF) as a bipolar electrode, a typical example was described (Fig. 2).

Nature Scientific Reports Vol. 12, Article number: 16537 (2022); https://doi.org/10.1038/s41598-022-20929-7

Zn-Mn/Al2O3 composite coatings

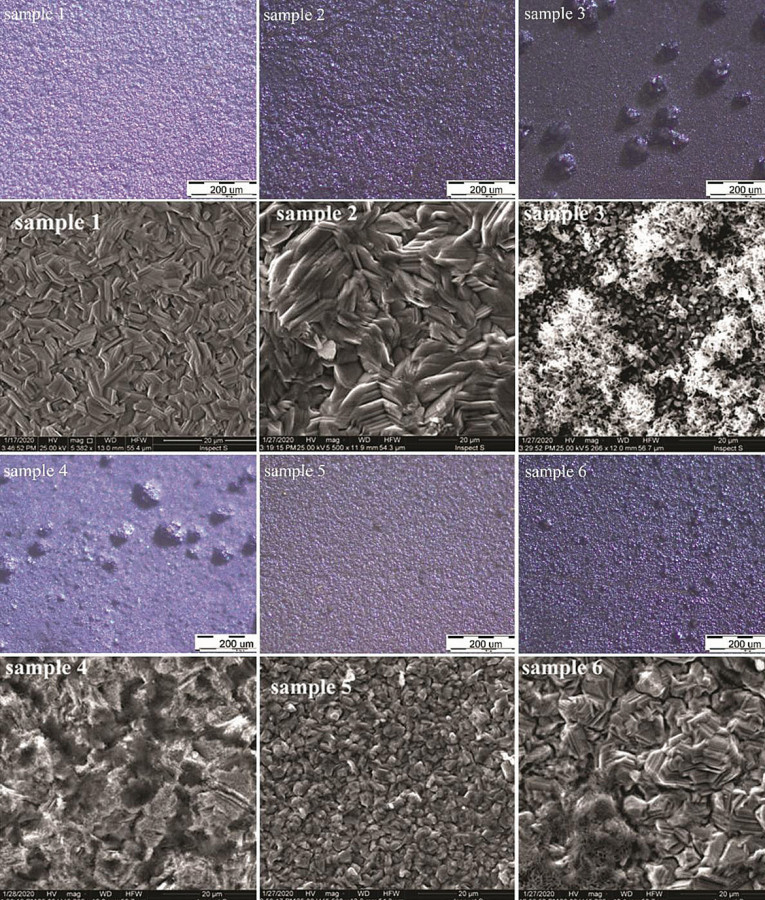

In a joint study, scientists from Belgrade and Zvornik have investigated the corrosion resistance and mechanical properties of novel Zn-Mn/Al2O3 composite coatings. The coatings were electrodeposited at constant current density on steel from a chloride bath at room temperature. Aluminum oxide particles with a particle size of 0.3 μm were incorporated into the Zn-Mn matrix at a concentration of 1.0 g dm-3 in the bath and the hardness and corrosion resistance of the resulting composite coatings were tested.

In order to achieve a good dispersion of the coating solution and a homogeneous deposition of the second phase, the coatings were stirred mechanically and with the aid of ultrasound. The incorporation of Al2O3 particles was improved by the mechanical movement of the solution. However, agglomeration of the aluminum oxide particles occurred. In contrast, when the coating solution was stirred with ultrasound, a uniform distribution of the aluminum oxide particles was achieved. The presence of particles in the matrix, together with the use of ultrasound, led to grain refinement and a homogeneous microstructure. The Al2O3 nanoparticles incorporated into the Zn-Mn alloy matrix led to a significant increase in the indentation hardness and an increase in the corrosion resistance of the coating. However, the coating hardness only increased with the addition of aluminum oxide when the electrodeposition solution was stirred ultrasonically (Fig. 3).

Fig. 3: Optical images of the surface morphology of the Zn-Mn and Zn-Mn/Al2O3 coatings deposited under different parameters

Fig. 3: Optical images of the surface morphology of the Zn-Mn and Zn-Mn/Al2O3 coatings deposited under different parameters

The Zn-Mn alloy coatings, which exhibit high corrosion resistance, could be used as an alternative to cadmium coatings in the future.

Indian J. Eng. Mater. Sci. 2022, 29, pp. 540-549

Maintenance, repair and overhaul of aircraft

It is well known that electroplating plays an important role in the maintenance, repair and overhaul (MRO) of aircraft.

ExecuJet Malaysia, a Dassault Aviation Company in Subang Airport, Selangor, Malaysia has expanded its in-house airframe and engine MRO capabilities to include zinc-nickel and cadmium electroplating. The removal and installation of engine fan casings has also been added.

With the ability to offer zinc-nickel and cadmium electroplating, the company no longer needs to outsource this work. With this technology in-house, ExecuJet also has better control over the workflow of heavy airframe maintenance work and can ultimately offer better turnaround times.