Quantum technologies and high-speed computers with superconductors are among the current trends in electronics. However, the structures that can be used to control qubits on chips and read them out in real time are still larger than the qubits themselves. Researchers at Fraunhofer IZM have now developed a process that doubles the connection density with indium bumps compared to previous solutions. They now want to use this technology to optimize the control electronics. They have also set up a cryogenic laboratory in Berlin to test the performance of their electronic assemblies.

Quantum processor with which Boehringer Ingelheim wants to optimize calculations for research and development in the pharmaceutical sector together with Google (Photo: Boehringer Ingelheim)Fans of science fiction are familiar with the process: the main character is frozen with the help of cryostasis and can be awakened from cryogenic sleep a few centuries later unharmed. Such utopias are based on very real science: cryogenics. This involves liquefying gases by exposing them to cryogenic temperatures of -160°C and even colder. While the findings of cryogenics were gained experimentally at the end of the 19th century, many industries have now recognized the benefits of extreme cold: In space travel, for example, cryo-sensors are used for gravity measurement or low-noise amplifiers for very weak signals. In cryosurgery, it is used to treat diseased tissue. Cryogenics is particularly relevant in the field of quantum technology. In order to realize the spectrum of quantum technologies from computing to sensor technology to quantum communication, the development of suitable and, above all, scalable production technologies is necessary. In order for a quantum computer to solve real calculations and thus accelerate applications, additional, controllable qubits are required - with hundreds of thousands to even millions of physical units, not exactly a few. These qubits are connected to each other by superconducting circuits, i.e. lines that have a barely measurable electrical resistance at certain temperatures.

Quantum processor with which Boehringer Ingelheim wants to optimize calculations for research and development in the pharmaceutical sector together with Google (Photo: Boehringer Ingelheim)Fans of science fiction are familiar with the process: the main character is frozen with the help of cryostasis and can be awakened from cryogenic sleep a few centuries later unharmed. Such utopias are based on very real science: cryogenics. This involves liquefying gases by exposing them to cryogenic temperatures of -160°C and even colder. While the findings of cryogenics were gained experimentally at the end of the 19th century, many industries have now recognized the benefits of extreme cold: In space travel, for example, cryo-sensors are used for gravity measurement or low-noise amplifiers for very weak signals. In cryosurgery, it is used to treat diseased tissue. Cryogenics is particularly relevant in the field of quantum technology. In order to realize the spectrum of quantum technologies from computing to sensor technology to quantum communication, the development of suitable and, above all, scalable production technologies is necessary. In order for a quantum computer to solve real calculations and thus accelerate applications, additional, controllable qubits are required - with hundreds of thousands to even millions of physical units, not exactly a few. These qubits are connected to each other by superconducting circuits, i.e. lines that have a barely measurable electrical resistance at certain temperatures.

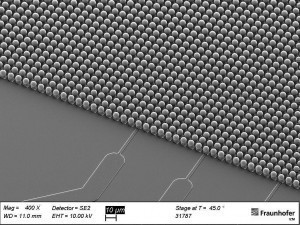

In order to be able to read and manipulate the qubits, an electrical circuit with the highest possible connection density is required. It must also be thermally decoupled so that the cooled qubits do not lose their entanglement due to their self-heating during operation. The so-called quantum superiority is only achieved with high qubit numbers, currently assumed to be 100,000 or even a million qubits. In many cases, the achievable qubit density on a semiconductor chip is limited by the contact density. With current technologies, it has not been possible for years to fall below the value of 15 micrometers for the connection pitch.

INFO

Impact of quantum mechanics

Quantum mechanics is one of the best-proven physical theories, without which our modern world would not be possible. Its fathers include Max Planck (Planck's quantum of action), Albert Einstein (photoelectric effect), Werner Heisenberg, Erwin Schrödinger, Max Born and others.

The word "quantum leap" in common parlance denotes the opposite of its actual physical meaning. In fact, it refers to the smallest possible energy conversion. How small such a change is can be recognized by the SI unit of Planck's quantum of action: 6.62607015∙10-34 J s.

The theory of quantum mechanics led to inventions such as lasers, electron microscopes, diodes, transistors and thus to modern electronics. It revolutionized atomic physics, chemistry (quantum chemistry) and astronomy.

For some years now, intensive research has been carried out on quantum computers. These are designed to calculate tasks that take classical computers a very long time much faster. The basis of such computers are qubits. A qubit is a system that is only correctly described by quantum mechanics and only has two states that can be reliably distinguished by measurement. It is analogous to the bit of a classical computer. Several qubits are combined to form quantum registers. One of the reasons for the efficiency of quantum computers lies in quantum entanglement.

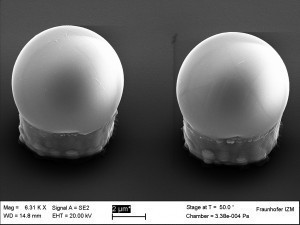

Hermann Oppermann from the Fraunhofer Institute for Reliability and Microintegration IZM have now succeeded in achieving a pitch of less than 7.5 µm by electrodepositing indium (read the interview with Dr. Hermann Oppermann and Morten Brink at the end of this issue). With ambient temperatures of 20 milli-Kelvin required during operation, the self-heating of the electrical cables must be extremely low. Superconducting materials are ideally suited for this. The researchers led by Hermann Oppermann have succeeded in depositing and structuring superconducting niobium and niobium alloys, which are used for wiring circuit carriers in several layers, so-called interposers, with vias. The result is extremely low-loss circuit carriers that can be used to control qubit arrays in real time and integrate them into high-density, scalable systems for quantum computers.

INFO

Indium electrolyte offers optimum properties

The experts at the Fraunhofer Institute for Reliability and Microintegration (Fraunhofer IZM) developed the electrolyte themselves to create the 7.5 µm thin indium bump (bump: contacting hill). The experts Brink and Dr. Oppermann did not want to say anything about the composition itself in the interview. However, they revealed that indium is used as an electrolyte because of its superconducting properties near absolute zero (approx. 270 degrees below zero) and its low-temperature toughness. Silver, for example, would tend to become brittle in these temperature ranges. The pH value of the electrolyte is approx. 1 and it is stable over the long term. The deposition itself takes place at around 30 °C, but room temperature is also possible. The Fraunhofer experts trim the bath so that the efficiency is almost 100 %. Indium-indium also has the advantage that it can be bonded down to room temperature. Gold and silver require higher temperatures for bonding. The current density in the electrolyte is 2-3 amperes per dm2. In order for the control of the qubits in the quantum computer to work, the galvanically deposited contacts between the bumps must be etched away. "We always work with a seat layer to create the contact over the entire process. However, we have to remove it afterwards, otherwise we have short circuits everywhere," says Morten Brink from Fraunhofer IZM.

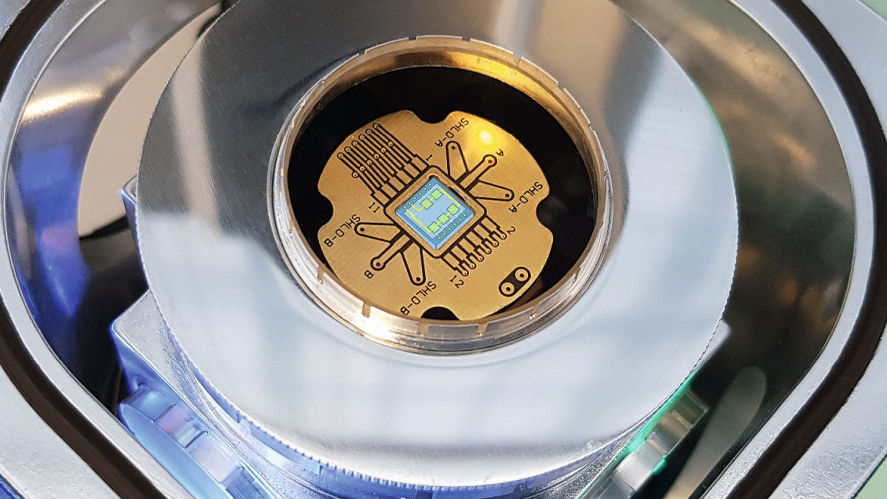

The cryomess laboratory was set up at Fraunhofer IZM in Berlin to create this technological basis, investigate materials, optimize integration concepts and develop superconducting assembly and connection technology for cryogenic applications. In the newly established test laboratory, researchers can characterize and evaluate electrical circuits and thus advance integration technologies for applications at ultra-low temperatures. By analyzing the resistance behavior of individual circuit components, which are cooled down to 3 Kelvin with a cooling finger under vacuum, the electrical behavior and reliability of the vias, rewiring levels and line systems can be evaluated at cryogenic temperatures.

In ongoing projects, initial measurements have already been taken and assembly and connection techniques as well as integration under cryogenic conditions have been advanced. "As one of the next steps, we see the expansion of cryogenic assembly and connection technology in the direction of high-frequency millimeter wave technology." Hermann Oppermann is confident: "Our growing expertise in this field offers broad market potential that extends beyond quantum technologies into classic application areas such as high-performance computing and cryo-sensor technology. We are open to further projects in which we take cryogenic applications to the next level with our packaging technologies."

Interview

Quantum computers, which work on the basis of quantum mechanical states rather than electrical states like PCs, promise a huge boost in computing power. Searches in huge databases could be accelerated, as could calculations of many mathematical and physical questions. A galvanically generated indium pitch developed by Fraunhofer IZM, i.e. a connection of component connections, now significantly increases the connection density of these computers - and thus increases their performance.

Dr. Oppermann, electroplating makes quantum computers more powerful. Why is that?

Morten Brink and Dr. Hermann Oppermann (from left to right)

Morten Brink and Dr. Hermann Oppermann (from left to right)

Oppermann: Because quantum computers need a very high connection density. Qubits have to be connected to other qubits, circuits and control electronics. Because the number of qubits increases the performance of the computer, it is necessary to become more compact. This is why our Feinpitchs are so important.

You have succeeded in producing 7.5 µm thin indium bumps using electroplating ...

Oppermann: Exactly, and the special thing is that indium bumps (contacting hills) are normally vapor-deposited, but pitches of less than 15 µm are hardly possible. The galvanic process is different - it is superior to vapor deposition. And the 7.5 µm that we have achieved is certainly an interesting milestone.

What system technology do you work with?

Brink: For wafer electroplating from 100 to 300 mm, there are semi-automatic or fully automatic fountain platers or copper platers in which the wafer is held upside down in the electrolyte. Rotation and a certain bath flow ensure homogeneity. The flow comes from below, while the anode sits under the wafer. When the current is switched on, deposition takes place. However, there is also the rack plating tool, which we use more frequently, in which the wafer is inserted vertically into the electrolyte. Using electrolyte and a fully automatic machine over 8 meters long, the wafers are handled and moved through the individual processes. There are no special requirements for the electrolyte.

How did you come to use electroplating?

Brink: We come from the field of high-energy physics and have a lot to do with infrared detectors and detectors of all kinds. They have to be connected and it was for these systems that we considered indium as a low-temperature connection and developed an electrolyte and a technology. The standard pitch was originally 55 µm. We have worked our way down from the top, partly because of requests from many customers who would prefer pitches below 7.5 µm.

How do you work with the industry?

Oppermann: As an institute, we use standard equipment as in industry. We use it flexibly for hundreds of projects every year. However, only in development and for small series. When it comes to commercial projects, we provide the know-how and offer process transfer for industry.

Interview: Robert Piterek

ABOUT THE PEOPLE

Dr. Hermann Oppermann

Is a materials scientist with a doctorate in metal physics and has been at Fraunhofer IZM since 1999. He heads a group for assembly technology and assembly.

Morten Brink

Is a chemist and graduated from Fraunhofer IZM in Berlin with a degree in metal deposition. He supervises infrared projects, among others.