Not a happy country

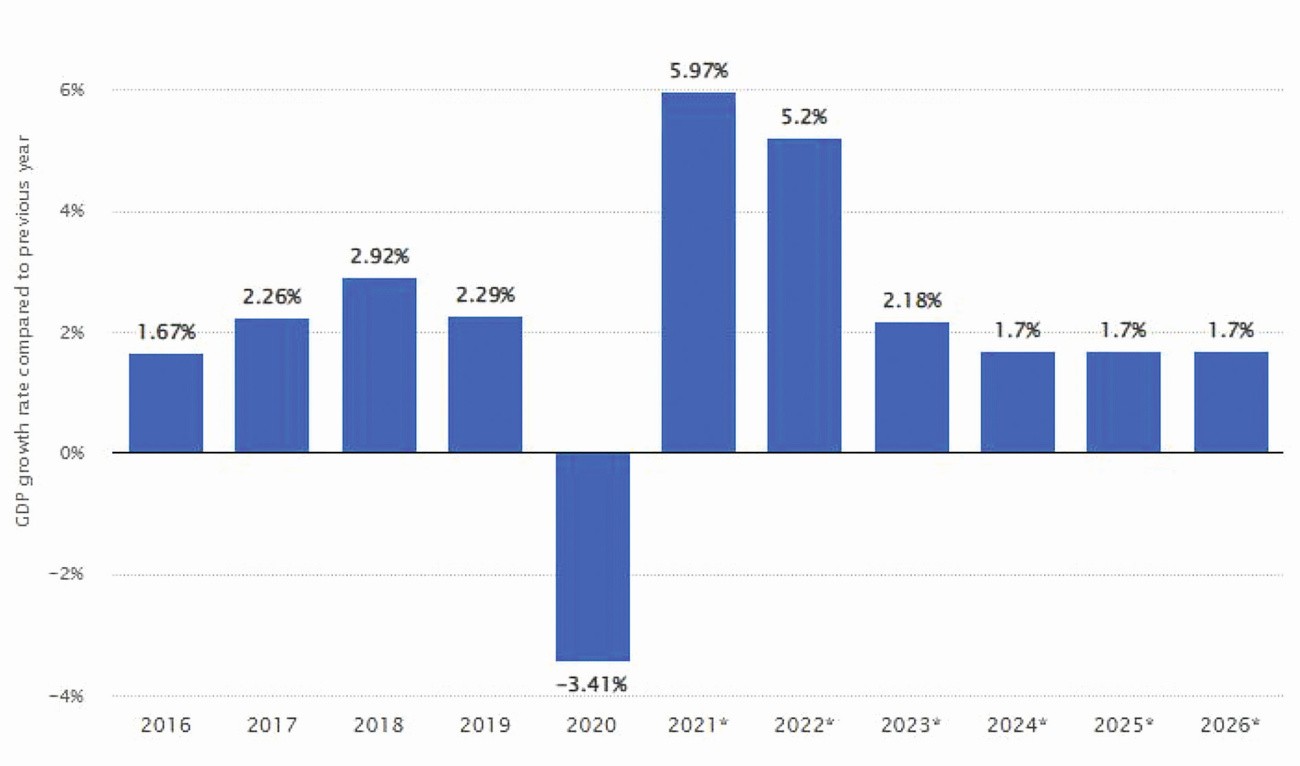

The US may be some 5000 km away from Europe, but it is still our most important ally, a major trading partner and a military shield that was important in the past and is vital today in the face of Russia's increasing aggression. So it is in our interest that America does well in general. Today, the US economy seems to be thriving. Unemployment is low and the economy is growing well (Fig. 1). We shouldn't be too concerned with projections for 2024 and beyond - it's simply impossible to see that far into the future.

But behind these statistics, all is not well. The US infrastructure - roads, railroads and bridges - is largely in poor condition and needs many billions of dollars in repairs. Medical care is the best in the world, but only for those who can afford it. We in Europe are concerned about illegal immigrants from Africa and other countries. But in the U.S., about 2 million migrants simply walked across the border from Mexico or waded through a shallow river in 2021 - a huge number. Former President Trump started building a wall, but only a small portion of the wall was ever completed, and President Biden offers no solution.

Fig. 1: USA economic growth, past, present and future

Fig. 1: USA economic growth, past, present and future

But perhaps the biggest fracture in the US is a political one. About a third of all American voters (mostly Republican voters) believe that the last election in 2020 was stolen and that President Trump should - rightly - be re-elected. He himself continues to claim this. There is not a scintilla of evidence to support this belief. Countless courts have investigated these claims and found nothing wrong. In many US states, Republicans are planning to make voting more difficult, which will discourage poorer people and black Americans from voting, thus favoring a future Republican victory. President Biden will soon be 80 years old, and many wonder if the burden of the presidency is not too heavy for such a man. The withdrawal of US forces from Afghanistan has been disastrous. Some have even speculated that there could be a second American civil war.

There are many other deep-rooted internal conflicts. In 1973, the US Supreme Court finally laid down the rules on abortion. Now the whole issue is back on the table as some states have enacted a de facto ban. The Democratic Party itself is deeply divided, with quasi-socialists like Senator Bernie Sanders and Congresswoman Ocasio- Cortez on one side and centrist Democrats like Biden himself on the other. Climate change has divided Americans much more deeply than Europeans, and when it comes to Covid, there are many more people than here who refuse vaccinations and refuse to wear a mask. There is so much more that could be added, but I will only mention the crazy theory of QAnon (readers can google it) which has many millions of American believers. There is very little we can do here in Europe to help the US and we have to resign ourselves to the fact that ex-President Trump (who will soon be 76 years old) could return to the Washington White House in 2024. Ora pro nobis?

The green road has its dangers

Fig. 2: A 220-ton mining truck needs 130 liters of diesel per hour The "green lobby" is powerful, and many politicians are desperately trying to win its support. In Germany, the Greens are strongly against coal, but also against other fossil fuels and also against nuclear power. It is easy to be against these technologies. But when it comes to alternatives, the Greens are less specific, wind and solar, yes, but they rarely offer concrete plans. All this the reader will know. As consumers, we are becoming more and more environmentally aware: more electric cars are being sold every year, and we are heating our homes and offices with heat pumps instead of natural gas. But it's time to ask a question. If the demand for electricity increases, will enough electricity be generated to meet this growing demand? We are in a strange situation where there seems to be no correlation between the growing demand for electricity on the one hand and the growth of green energy sources on the other. At least in theory, we could use more coal-fired power plants to meet the growing demand for electricity. What's more, Germany, like some other European countries, gets about 40% of its energy from Uncle Vladimir. And if we do anything that displeases him, he can simply turn off the tap, or at least turn it halfway off. Let's be honest: we are not in a strong position. I sometimes get the feeling that the Greens are not prepared to accept this truth. We are seeing some amazing developments in technology, and I'll talk about some of them below. But most of these advances relate to devices that consume electricity, while there is less to report in terms of electricity generation.

Fig. 2: A 220-ton mining truck needs 130 liters of diesel per hour The "green lobby" is powerful, and many politicians are desperately trying to win its support. In Germany, the Greens are strongly against coal, but also against other fossil fuels and also against nuclear power. It is easy to be against these technologies. But when it comes to alternatives, the Greens are less specific, wind and solar, yes, but they rarely offer concrete plans. All this the reader will know. As consumers, we are becoming more and more environmentally aware: more electric cars are being sold every year, and we are heating our homes and offices with heat pumps instead of natural gas. But it's time to ask a question. If the demand for electricity increases, will enough electricity be generated to meet this growing demand? We are in a strange situation where there seems to be no correlation between the growing demand for electricity on the one hand and the growth of green energy sources on the other. At least in theory, we could use more coal-fired power plants to meet the growing demand for electricity. What's more, Germany, like some other European countries, gets about 40% of its energy from Uncle Vladimir. And if we do anything that displeases him, he can simply turn off the tap, or at least turn it halfway off. Let's be honest: we are not in a strong position. I sometimes get the feeling that the Greens are not prepared to accept this truth. We are seeing some amazing developments in technology, and I'll talk about some of them below. But most of these advances relate to devices that consume electricity, while there is less to report in terms of electricity generation.

Going electric

Australia is a paradox. The country is the second largest exporter of coal in the world. However, as this coal is burned overseas (mainly in India), the country is only classified as a moderateCO2 emitter. However, the country's mining industry is working hard to reduce emissions. Mining trucks (Fig. 2) are among the largest wheeled vehicles in the world, weighing 220 tons and consuming over 130 liters of diesel per hour.

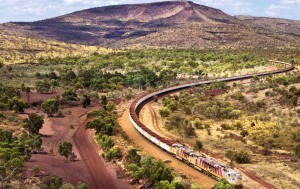

Fig. 3: Iron ore trains more than 2 km long will be battery-powered The international mining giant Anglo American is working with several partners to retrofit one of these behemoths with hydrogen technology. The vehicle is the first of its kind and is being tested at the Mogalakwena platinum mine in Limpopo, South Africa. The truck, which is due to be launched early this year, will be a hybrid vehicle, with a hydrogen fuel cell providing around half of the electricity and a battery pack providing the other half. Instead of a diesel tank powering the engine, a hydrogen-oxygen fuel cell will provide the electricity to drive the wheels. According to the company, this can reduce diesel emissions on site by up to 80%. By introducing this technology into its global truck fleet, particularly in Australia and Africa, Anglo American says it will "take the equivalent of half a million diesel cars off the road".

Fig. 3: Iron ore trains more than 2 km long will be battery-powered The international mining giant Anglo American is working with several partners to retrofit one of these behemoths with hydrogen technology. The vehicle is the first of its kind and is being tested at the Mogalakwena platinum mine in Limpopo, South Africa. The truck, which is due to be launched early this year, will be a hybrid vehicle, with a hydrogen fuel cell providing around half of the electricity and a battery pack providing the other half. Instead of a diesel tank powering the engine, a hydrogen-oxygen fuel cell will provide the electricity to drive the wheels. According to the company, this can reduce diesel emissions on site by up to 80%. By introducing this technology into its global truck fleet, particularly in Australia and Africa, Anglo American says it will "take the equivalent of half a million diesel cars off the road".

Another international mining giant, Rio Tinto, has ordered four battery-powered trains to transport its iron ore wagons in Australia in a bid to reduce its carbon emissions. The Anglo-Australian mining company announced that it will test the locomotives in the Pilbara region from 2024 in order to halve its operational emissions by 2030. Rio Tinto currently operates 220 diesel locomotives on a 1500 km rail network in the Pilbara, where they transport the company's iron ore over distances of up to 450 km from the mines to the port. The huge iron ore trains are usually 2.4 km long and require three diesel locomotives to transport the freight (Fig. 3).

Rio has ordered four battery-electric locomotives from the American Wabtec Corporation, which are to be produced from 2023. They will be charged at new charging stations in the ports and mines and "will be able to generate additional energy during the journey through a regenerative braking system that extracts energy from the train and uses it to recharge the on-board batteries". Rio Tinto is one of the largest mining companies in the world and recorded a net profit of 12.3 billion dollars in the first half of last year. The company makes most of its profits from mining iron ore in the Pilbara region of Australia, most of which is then shipped to China, where it is used to make steel in a highly emissions-intensive process using coking coal.

Hydrogen - Background

Fig. 4: Hydrogen pump for cars and trucks at highway filling stations I have written here and previously about hydrogen-powered cars, trucks, trains and airplanes. Most of these are powered by fuel cells, but we have seen that fuel engines can also run on hydrogen. But behind all these applications is the common technology of storing hydrogen (as compressed gas or liquefied) and the associated pipelines. Metallurgists have long been aware of the embrittlement of metals by hydrogen, and thanks to its smaller molecules, hydrogen can escape more easily through small pores. Industries have now developed that specialize in the storage and handling of hydrogen, making it easier for end product developers to create new products. One such company is Haskel (www.haskel.com), based in Sunderland, UK. It manufactures a wide range of hydrogen storage and handling equipment and also offers testing facilities for such items. The company has recently signed a contract with aircraft manufacturer ZeroAvia (www.zeroavia.com) to act as a subcontractor for the development of hydrogen-powered aircraft. In addition, Haskel is now supplying hydrogen refueling stations on highways (Fig. 4), and there are a growing number of similar companies, all facilitating the development of hydrogen technologies.

Fig. 4: Hydrogen pump for cars and trucks at highway filling stations I have written here and previously about hydrogen-powered cars, trucks, trains and airplanes. Most of these are powered by fuel cells, but we have seen that fuel engines can also run on hydrogen. But behind all these applications is the common technology of storing hydrogen (as compressed gas or liquefied) and the associated pipelines. Metallurgists have long been aware of the embrittlement of metals by hydrogen, and thanks to its smaller molecules, hydrogen can escape more easily through small pores. Industries have now developed that specialize in the storage and handling of hydrogen, making it easier for end product developers to create new products. One such company is Haskel (www.haskel.com), based in Sunderland, UK. It manufactures a wide range of hydrogen storage and handling equipment and also offers testing facilities for such items. The company has recently signed a contract with aircraft manufacturer ZeroAvia (www.zeroavia.com) to act as a subcontractor for the development of hydrogen-powered aircraft. In addition, Haskel is now supplying hydrogen refueling stations on highways (Fig. 4), and there are a growing number of similar companies, all facilitating the development of hydrogen technologies.

Major hydrogen supply contract

Construction equipment manufacturer JCB has signed a multi-billion dollar contract to import and supply hydrogen produced from renewable energy. The company announced an agreement with Australia's Fortescue Future Industries (FFI) that will enable it to sell 'green' gas in the UK through a specialist division, Ryze Hydrogen (www.ryzehydrogen.com), from early next year. The website reports on the latest developments in the use of hydrogen as an energy source.

Hydrogen already powers buses in many countries, including the UK, and could power trucks, trains and other high energy-consuming vehicles, including aircraft. Areas that are currently considered difficult to decarbonize. FFI's green hydrogen is produced from 100% renewable sources.

JCB CEO Anthony Bamford, whose company Wrightbus built the world's first hydrogen double-decker bus, described the agreement as an important step towards a greener energy supply for commercial customers.

FFI chairman Andrew Forrest said the agreement would help the UK meet its net zero targets, particularly in hard-to-electrify sectors. The reduction in greenhouse gas emissions associated with replacing fossil fuels with just 2 million tons of green hydrogen is equivalent to taking over 8 million cars off the road - almost a quarter of the UK's entire fleet.

Going green - at home

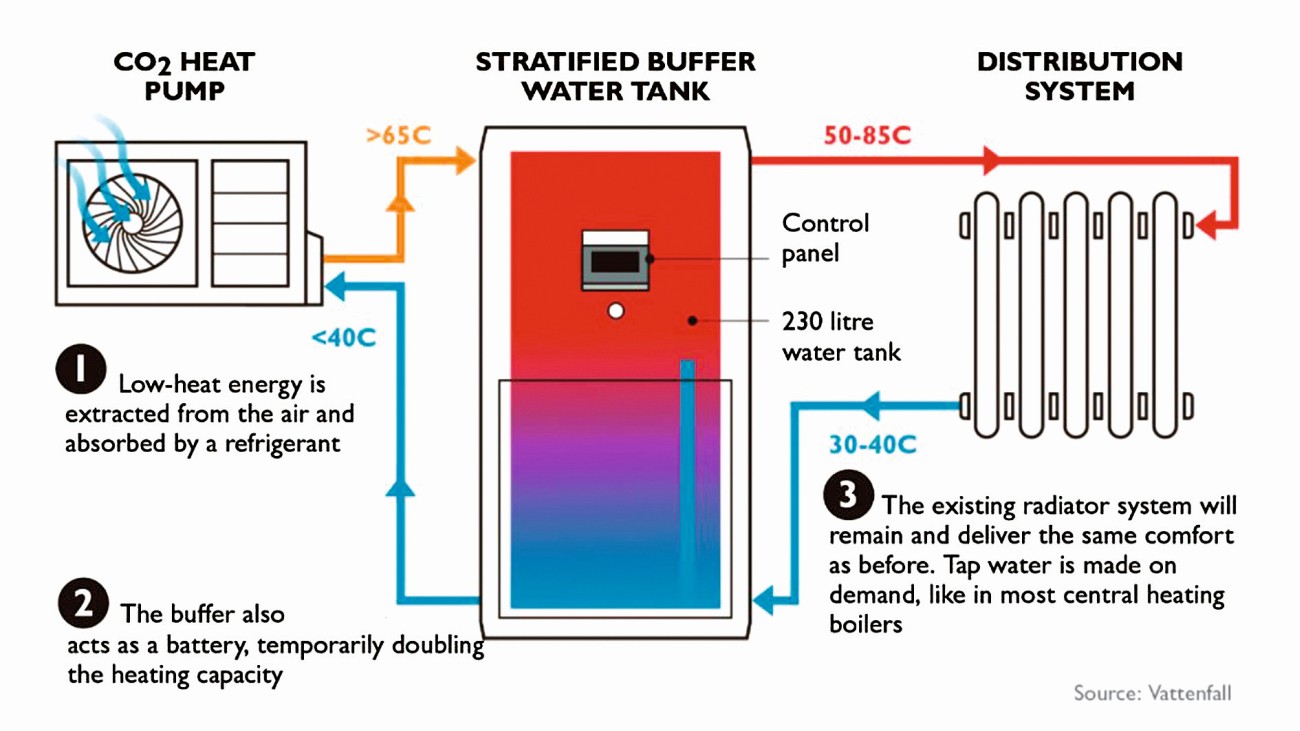

Will we be heating our homes and offices with hydrogen delivered via the gas grid, or with electricity powered by heat pumps? I have never come across a discussion about this. Heat pumps have been around for many years, but until recently they had the problem that they could not easily raise the hot water temperature above about 50 °C. For this reason, additional insulation or a larger radiator may be required when installing them in existing buildings (so-called retrofit). A new type of heat pump system that can supply hot water at the same temperature as gas boilers could make it easier and cheaper for households to switch to low-carbon heating. Vattenfall, the Swedish state-owned energy company, is promoting this technology (Fig. 5).

Fig. 5: The new high-temperature heat pump from Vattenfall

Fig. 5: The new high-temperature heat pump from Vattenfall

The company is launching the system in the Netherlands in the next few months and says it could then be rolled out in other European countries. The new technology enables a "direct replacement" of the existing gas boiler with the heat pump without the need for further modifications, with the exception that the new system requires the installation of a large hot water tank in the house to work with the heat pump. This is larger and heavier than hot water tanks used with other heat pump systems or gas boilers, although Vattenfall says that most rural and suburban homes should have enough space to accommodate this larger tank. Vattenfall states that the price of its system "will be comparable to current low and medium temperature heat pumps, but without the additional cost of retrofitting insulation and/or underfloor heating".

Unlike most conventional heat pump systems, Vattenfall's technology uses carbon dioxide as a refrigerant instead of hydrofluorocarbons or similar gases. Other systems that use carbon dioxide cannot work with most existing central heating systems because the water that flows back into the heat pump from the radiators is still too hot, so the heat pump cannot work properly as it needs cold water for cooling.

The Vattenfall pump is combined with a 230-liter stratified buffer tank. This allows the water that flows back to the heat pump to be cooled and stores enough hot water to heat a house quickly, even with poor insulation. The tank is about 1.5 m high, weighs more than 300 kg and requires a solid floor area of about 1.5 m x 1 m for installation.

See it, touch it and now: taste it!

Fig. 6: Interior view of the new taste machine A Japanese professor has invented a "tasting machine". Soon, shoppers will be able to taste what's on offer before they buy by using a TV with a lickable screen. The professor from Meiji University in Tokyo has unveiled a new prototype called Taste the TV (TTTV), which is equipped with ten flavor containers that create the taste of different foods and drinks. The flavors are transferred to the screen on a roll of disposable film and can be licked by viewers. "The aim is to give people the experience of eating at a restaurant on the other side of the world, even if they stay at home," Homei Miyashita, assistant professor at Meiji University, told reporters at a demonstration. Figure 6 shows the inside of the device, which has 10 canisters, each with a specific flavor.

Fig. 6: Interior view of the new taste machine A Japanese professor has invented a "tasting machine". Soon, shoppers will be able to taste what's on offer before they buy by using a TV with a lickable screen. The professor from Meiji University in Tokyo has unveiled a new prototype called Taste the TV (TTTV), which is equipped with ten flavor containers that create the taste of different foods and drinks. The flavors are transferred to the screen on a roll of disposable film and can be licked by viewers. "The aim is to give people the experience of eating at a restaurant on the other side of the world, even if they stay at home," Homei Miyashita, assistant professor at Meiji University, told reporters at a demonstration. Figure 6 shows the inside of the device, which has 10 canisters, each with a specific flavor.

The professor envisions that TTTV could be used for sommelier training, quiz games and digital menus in restaurants, among other applications. He is in talks with companies about using the technology for devices that can spray flavors on toast and other foods.

At the demonstration, Yuki Ho, 22, a Meiji University student, told the screen that she wanted to taste sweet chocolate. After a few tries, the machine confirmed the order and sprayed the flavor onto a foil. "It's a kind of milk chocolate. It's sweet like a chocolate sauce," the machine told the test subject.

Miyashita and the 30 students in his lab have also developed other flavor-related technologies, such as a fork that enhances the taste of food eaten with it. The inventor said he hopes such technologies could strengthen connections and interactions between people during the pandemic. The TTTV was awarded bronze in the creative innovation category at the 61st ACC Tokyo Creativity Awards last month.

Miyashita built the prototype himself and estimates that it could come onto the market at a price of around 100,000 yen (about 700 euros). Can we take this seriously? Is it really possible to mimic the hundreds or thousands of different flavors of our everyday food and drink by mixing the contents of just ten flavor containers?

At home

Fig. 7: The Oxwash plant What do we make at home, and what do we commission by buying it in a store or using a service? For hundreds of years we have bought our bread from the baker or, more recently, from the supermarket. Then, about 20 years ago, the bread baking machine came onto the market. My impression is that many housewives put it back in the cupboard after their initial enthusiasm and returned to the bakery. A similar story applies to our laundry. In the past, every housewife did her own laundry. Then, in the late 19th century, commercial laundries would collect the laundry from the house and bring it back a few days later. This system was used, but only by those families who could afford it. In the 1960s, the "Laundromat", a business with coin-operated washing machines for self-service, arrived from the USA. But a decade later, more and more households owned their own washing machine, and this is still the case today. In parts of England, brave entrepreneurs are now trying to reverse this trend. Most domestic washing machines consume large amounts of energy and water, typically 10 liters of water per kilogram of laundry. Oxwash technology can reduce this consumption by saving up to 32 liters on a standard 8 kg wash load thanks to its water filtration and recovery techniques. In addition, an enormous 14,000 tons of microfibers are released into the oceans every year through global laundry use - meaning that a third of all plastic found in the ocean is microfibers from clothing. We now know that such fibers are ingested by fish and other marine life and can eventually end up in humans. Oxwash's proprietary microfiber filtration technology also removes more than 95% of the fibers that come loose during washing, preventing plastic pollution from entering waterways and drinking water. With their filtration technology, Oxwash machines prevent more than 1 million plastic microfibers per kilogram of laundry from entering water systems.Figure 7 shows the system.

Fig. 7: The Oxwash plant What do we make at home, and what do we commission by buying it in a store or using a service? For hundreds of years we have bought our bread from the baker or, more recently, from the supermarket. Then, about 20 years ago, the bread baking machine came onto the market. My impression is that many housewives put it back in the cupboard after their initial enthusiasm and returned to the bakery. A similar story applies to our laundry. In the past, every housewife did her own laundry. Then, in the late 19th century, commercial laundries would collect the laundry from the house and bring it back a few days later. This system was used, but only by those families who could afford it. In the 1960s, the "Laundromat", a business with coin-operated washing machines for self-service, arrived from the USA. But a decade later, more and more households owned their own washing machine, and this is still the case today. In parts of England, brave entrepreneurs are now trying to reverse this trend. Most domestic washing machines consume large amounts of energy and water, typically 10 liters of water per kilogram of laundry. Oxwash technology can reduce this consumption by saving up to 32 liters on a standard 8 kg wash load thanks to its water filtration and recovery techniques. In addition, an enormous 14,000 tons of microfibers are released into the oceans every year through global laundry use - meaning that a third of all plastic found in the ocean is microfibers from clothing. We now know that such fibers are ingested by fish and other marine life and can eventually end up in humans. Oxwash's proprietary microfiber filtration technology also removes more than 95% of the fibers that come loose during washing, preventing plastic pollution from entering waterways and drinking water. With their filtration technology, Oxwash machines prevent more than 1 million plastic microfibers per kilogram of laundry from entering water systems.Figure 7 shows the system.

Fig. 8: Laundry transportation with electrically powered vehicles

Fig. 8: Laundry transportation with electrically powered vehicles

The Oxwash process also kills bacteria through a three-stage cycle (ozone disinfection, chemical sterilization and thermal decontamination) that is so advanced that it reduces 99.99999% of infections - 100 times better than the standard required in most hospitals. The company claims to reduceCO2 emissions per kg of linen by 45% and, in most cases, collects and returns linen to customers using electric delivery vehicles (Fig. 8).