A changed landscape: shopping

As England, like other nations, struggles to emerge from a year of pandemic and lockdowns, we are finding that there have been significant changes. We all know that bars, restaurants, hotels and airlines have had a very difficult year. But the real battle seems to have been in the fashion and clothing stores for men and women. In the UK, most of the big fashion chains - Debenhams, Miss Selfridge, Topshop, Oasis, Cath Kidston and many others - have gone bankrupt. It is estimated that almost 500,000 retail workers will have lost their jobs in 2020 and 2021.

The good news is that every single one of these chains has been bought out of bankruptcy. But the less good news is that in each case, the buyer only bought the brand name and the inventory of clothing - but not a single actual store. Thousands of fashion stores in the city center will soon be empty. We are told that England is the European country that has made the biggest transition to internet shopping. In England, around 55% of all non-food purchases are now made online, as are around 16% of food and drink purchases, up from 8% in 2019. The experts tell us that these percentages will increase in the coming years.

Let's take a moment to think about the traditional store in the city center. How much has it changed over the last 200 years or so? If our great-grandparents were to visit such a store, I think they would feel very comfortable there. Could you say that the "technology" of the Stadtmitte store hasn't changed in over 100 years? That wouldn't be entirely true. The biggest single change, especially after the world war, was the introduction of self-service. That was indeed a major revolution. But since then? Very little has changed. There was a plan for every single item in the store to be tagged with an RFID (radio frequency identification) chip, so that an entire shopping basket could be scanned instantly at the checkout. However, this does not seem to have happened. In recent years, Amazon has opened a very small number of stores with multiple cameras that record every item the customer puts in their basket and automatically deduct payment so that the customer can simply walk out of the store with no checkout (Fig. 1).

We don't know how successful this technology is, and in any case there is no recent news. In contrast, the whole technology of online shopping is evolving almost every month, with more and more highly automated warehouses (Germany is the world leader in this technology) and many new ideas for delivering purchases to the customer's doorstep. If online shopping is in itself a more cost-effective way of shopping, it's hard to see a bright future for the traditional store. If I can sit at home or in the office and "visit" several different suppliers within a few minutes while comparing their products and prices, why should I make another physical trip? Yes, I hear voices telling me that the family trip on Saturday was a pleasure, and I accept that. But if England has one lesson for its European neighbors, it's that online will be the winner.

A changed landscape: WFH

In the English-speaking world, the new acronym WFH needs no explanation. It stands for "Working from Home" and is on everyone's lips. The pandemic has shown that WFH is entirely possible for many employees. But is it a good thing? WFH saves money and time, both for the employer and the employee. Both the time and the cost of commuting to work are saved. For the employer, a smaller office with fewer desks means savings on rent, heating etc. But there can also be disadvantages, such as a lack of team spirit or interaction between colleagues. Some studies have shown that working from home increases or at least does not decrease productivity. There are many jokes, e.g. men who meet via Zoom wear fine shirts and ties - but below the belt only their underpants!

But the biggest single issue is that of trust. Can the manager trust his WFH employees to work honestly and not waste their time surfing the internet or playing with their cat? There is a new generation of software packages that allow managers to monitor their employees remotely. Some would call it spying on their employees. Prodoscore (www.prodoscore.com) allows management to monitor employees' daily activities, how many emails they have sent, how long they have spent on the internet etc. A similar product is Transparent Business (www.transparentbusiness.com). Two others are Hubstaff (www.hubstaff.com) and Time Doctor (www.timedoctor.com). I am sure there are many others. These programs allow managers to look over the shoulders of their employees. Some will argue that this implies a lack of trust in remote workers. In all of this, I don't want to pass judgment. It's clear that WFH can bring big savings for givers and takers. In the last 12 months, many English rail services have had less than 25% of normal passenger numbers. Some are advocating the so-called hybrid model, where staff might go into the office two days a week. There are so many issues. If an employee saves two hours a day in travel time by working from home, should they share that benefit with their employer? And finally, is WFH "greener" than traveling to the office? So many questions and managers and their employees will have to work out their own solutions. For now, it seems that modern tech companies like Microsoft, Google and Apple are mostly happy to have at least some WFH, while older companies like banks, Goldman Sachs and others, mostly want a return to the ways of the past.

Thanks to WFH, rail ridership is currently only 30% of normal. And the cost of office space (to buy or rent) has fallen by around 20%. We have an interesting year ahead of us!

Progress on the railroads

Trains have become faster and faster over the last few decades, but currently they seem to be stuck at around 320 km/h top speed. True, a French TGV has reached a speed of 575 km/h - and that was in 2007. A Japanese maglev train reached a speed of 600 km/h in 2015, and Elon Musk's Hyperloop (which is not a train) has ambitions to reach 1000 km/h or more.

And so to China! A train being developed in China will be able to travel the equivalent of London to Edinburgh in just over an hour. Researchers at Southwest Jiaotong University in Chengdu say the 21-meter-long locomotive can reach a top speed of 600 km/h, almost twice as fast as the Japanese bullet train. The new train was recently spotted for the first time on a 165-meter test track. It uses high-temperature superconducting maglev technology, which scientists hope will eventually reach speeds of more than 1000 km/h when combined with vacuum tube technology(Figs. 2 and 3).

Experts hailed the test as a milestone, according to the official Xinhua news agency. "In the past, everyone saw it as a laboratory toy without testing in a real situation," said Deng Zigang of the university's research program.

Xinhua reported: "The next step is to combine the vacuum tube technology and lay the foundation to reach the speed of more than 1000kmh."

China has about 38,000 kilometers of high-speed rail lines where trains can travel at speeds of up to 350kmh. Beijing has the ambition to develop the fastest trains in the world. The first maglev train, which connects downtown Shanghai with Pudong International Airport at 430 km/h, is based on German technology. It was opened in 2003. Two years ago, the prototype of a 600 km/h maglev train was unveiled in a city in eastern China.

CRRC Corp, a state-owned rolling stock manufacturer that is now the largest train manufacturer in the world, began research on the maglev train in 2016. Mr. Deng said the high-temperature superconductor technology is more suitable for the futuristic concept of super-fast transportation in vacuum tubes. "The technology can levitate the train without electricity, and it can be moved with just one hand," he explained. The advance of Chinese technology seems relentless - and I think we should all be rather frightened.

China: Not just railroads, but cars too

Fig. 4: The Wuling, a Chinese VolkswagenAbudget electric car that sells for around 4200 euros in China is now outselling Tesla's more expensive cars.

Fig. 4: The Wuling, a Chinese VolkswagenAbudget electric car that sells for around 4200 euros in China is now outselling Tesla's more expensive cars.

The compact car is proving to be a big hit for state-owned SAIC Motor, China's top carmaker. The Hong Guang Mini EV is being built as part of a joint venture with US auto giant General Motors (GM). Last month, sales of the low-cost electric car in China were about double that of Tesla, which has been questioned this month over safety issues. While the affordable Hong Guang Mini is the most popular model, there is an upgraded model with air conditioning for around 5000 euros. The cars are marketed as "the people's commuting tool". The Wuling shown in Figure 4 is seen as "the people's car", like the original German Volkswagen in the 1930s.

The joint venture partnership, SAIC-GM-Wuling, is known locally as the Wuling. Auto experts say that while it lags well behind Tesla when it comes to battery, range and performance, its convenience and low price have made it one of the best-selling new-energy vehicles in China. The basic model, which was launched last year, has a top speed of 100 km/h and offers space for four people in a very small area. According to experts, China's government is serious about reducing pollution and wants to become a world leader in introducing and promoting innovation in electric vehicles.

To promote e-vehicles, the Chinese government is offering fast and free delivery of license plates. In contrast, in many cities it can take months, if not years, to get a license plate for a petrol car through various auction systems. Could such a car have a market here in Europe? As a second car, with perhaps a range of 100 km, for shopping or commuting to work without question. And its batteries would be manufactured in Chinese plants located here in Europe. There are rumors that the Wuling could be produced by a Latvian car manufacturer who could sell a version of the car in Europe. However, the price would probably be twice as high due to European environmental regulations.

China and Russia - no comparison

Only a fool would deny the advance of Chinese power. With its huge population of 1.4 billion and astonishing technological progress, one has to conclude that China will soon be the world's number one power. I report on technological progress with admiration - but also with fear. But what about Russia, like China a huge country, a socialist dictatorship, but with a population of 144 million, almost 10 times smaller than China? I can't remember the last time I read about a significant new technology coming out of Russia - except in the area of military weapons. So the latest news is the (apparently successful) test of their new Sarmat RS-28 missile. 35 m high, 3 m in diameter, range 10 000 km, weight 208 tons with up to 16 nuclear warheads, it is indeed a most formidable weapon, and it may indeed be true that this missile is unstoppable with current technology. But suppose the Russians were to launch one or even half a dozen of these fearsome missiles, what would be the response? Most likely, Western submarines would launch their own nuclear missiles against Russian targets. And so the world would find itself in the so-called MAD (mad) situation, Mutually Assured Destruction. That Russia is apparently investing so much of its limited but valuable intellectual capital in military R&D seems a terrible waste of national resources.

Which leads me to thoughts about global warming. This is already damaging parts of Africa and perhaps soon southern Europe. But for Russia, at least so far, global warming hasn't been bad. The Arctic seas are now navigable most of the year and one would expect harvests in Siberia to improve. On the other hand, the melting of the so-called. In contrast, the melting of the so-called permafrost could release large quantities of methane - which would then pose a problem not only for Russia, but for us all. Global warming will affect us all, but some more than others, and this is a discussion we have heard very little about.

Spectacles - 700 years of progress

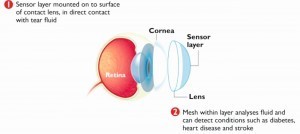

Fig. 5: The new smart contact lens It is thought that the first spectacles were developed in Italy around the year 1290. Since then, there has been an amazing stream of progress. Bifocal lenses, glasses with a high refractive index (the German company Schott led the way here), contact lenses, photochromic lenses, glasses with a built-in hearing aid - and the progress continues to this day. A contact lens that can improve vision while monitoring diseases such as diabetes and stroke has been developed. The device, designed by British, American and Chinese scientists, can also check the risk of heart disease by measuring chemicals in the tear fluid, according to researchers. It contains an electronic network equipped with light, temperature and glucose detectors. Figure 5 shows the principle of the new device.

Fig. 5: The new smart contact lens It is thought that the first spectacles were developed in Italy around the year 1290. Since then, there has been an amazing stream of progress. Bifocal lenses, glasses with a high refractive index (the German company Schott led the way here), contact lenses, photochromic lenses, glasses with a built-in hearing aid - and the progress continues to this day. A contact lens that can improve vision while monitoring diseases such as diabetes and stroke has been developed. The device, designed by British, American and Chinese scientists, can also check the risk of heart disease by measuring chemicals in the tear fluid, according to researchers. It contains an electronic network equipped with light, temperature and glucose detectors. Figure 5 shows the principle of the new device.

The researchers hope the invention could help combat medical emergencies. They are confident that devices using the new sensor layer system could be used as non-invasive methods for monitoring and diagnosing people's health. The project involved the National Physical Laboratory in London, Harvard University, George Washington University and the University of Science and Technology of China. The results were published in the journal Matter. Dr. Shiqi Guo, a researcher at Harvard, said: "Our ultrathin sensing layer is different from the conventional smart contact lenses with their rigid or massive sensors and circuit chips sandwiched between two contact lens layers and in contact with the tear fluid through microfluidic sensing channels. This new layer could instead be mounted on a contact lens and have direct contact with the tears thanks to its easy mounting, high detection sensitivity, good biocompatibility and mechanical robustness. In addition, it does not interfere with blinking or vision." This is not the first attempt to develop a smart contact lens. Mojo Vision, a Californian start-up company, has invested more than 100 million dollars in the development of a lens with an LED display. It uses a processor from the British chip designer Arm, which, according to Mojo, controls the world's smallest LED display with 300 pixels on half a millimeter. The display is integrated with a thin-film battery and an antenna inside the lens, which communicates with a computing and battery pack. This connects wirelessly to a smartphone, which streams content to the display. Steve Sinclair, Head of Product Development at Mojo, said: "We need to build something that shows you information that doesn't distract you, that helps you, that goes away when you don't need it and that stays away when you don't want it."

Source: "Integrated Contact Lens Sensor Sysyem Based on Multifunctional Ultrathing MoS2¬ Transistors". Shiqi Guo et al. booklet. Matter". Dec, 30 2020. https://doi.org/10.1016/j.matt.2020.12.002

Adjustable glasses

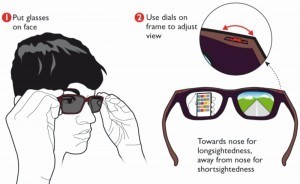

Fig. 6: How the new Voy glasses work"Where did I put these damn glasses?" The days of frantically searching the house for a missing pair of reading glasses could soon be over. A company has unveiled tunable glasses that can change their strength by turning a knob, depending on what the wearer is using them for. Voy(www.voyglasses.com), an American company, describes them as "nano-precision glasses" that allow the user to adjust their focus in seconds for different activities, from reading to driving, with a knob embedded in the temple of the glasses. The optical performance of the glasses covers a range from -5 for short-sighted people to +2 for long-sighted activities (Fig. 6). It is based on a technology developed in the 1960s by Nobel Prize-winning physicist Luis Walter Alvarez, which is based on two polycarbonate plates on each side that slide over each other when the dial is turned. The position of the plates determines the thickness of the lenses. A company in Oxford called Adlens developed a similar product in 2015, but has since moved on to designing lenses for virtual reality headsets. The Voy goggles were nominated for an innovation award at CES, the world's largest technology conference, which is only taking place online this year due to the pandemic.

Fig. 6: How the new Voy glasses work"Where did I put these damn glasses?" The days of frantically searching the house for a missing pair of reading glasses could soon be over. A company has unveiled tunable glasses that can change their strength by turning a knob, depending on what the wearer is using them for. Voy(www.voyglasses.com), an American company, describes them as "nano-precision glasses" that allow the user to adjust their focus in seconds for different activities, from reading to driving, with a knob embedded in the temple of the glasses. The optical performance of the glasses covers a range from -5 for short-sighted people to +2 for long-sighted activities (Fig. 6). It is based on a technology developed in the 1960s by Nobel Prize-winning physicist Luis Walter Alvarez, which is based on two polycarbonate plates on each side that slide over each other when the dial is turned. The position of the plates determines the thickness of the lenses. A company in Oxford called Adlens developed a similar product in 2015, but has since moved on to designing lenses for virtual reality headsets. The Voy goggles were nominated for an innovation award at CES, the world's largest technology conference, which is only taking place online this year due to the pandemic.

On the way to "green" steel

Steel production, on which our entire society depends, remains one of the biggest emitters ofCO2, accounting for 15% of industrial emissions in the UK and 9% of global emissions. There have been many proposals to solve this problem, such as using hydrogen or plastic waste as fuel. However, an Indian scientist working in Australia has come up with two ideas. One already seems to be working well, but I don't see the other being successful. Professor Sahajwalla's first idea is to use used tires, and this is already working well in Australian steel production. Figure 7 shows Professor Sahajwalla in her laboratory at the University of New South Wales, Australia.

Fig. 7: Professor Sahajwalla in her labProfessorVeena Sahajwalla from the University of New South Wales in Sydney has developed a technique that eliminates the need for coal in steel production. She is in talks with Molycop, a company that is already using a version of her technology. Molycop (molycop.com) is in talks with interested UK manufacturers.

Fig. 7: Professor Sahajwalla in her labProfessorVeena Sahajwalla from the University of New South Wales in Sydney has developed a technique that eliminates the need for coal in steel production. She is in talks with Molycop, a company that is already using a version of her technology. Molycop (molycop.com) is in talks with interested UK manufacturers.

Coal - or its purified form, coke - is an essential part of steel production, as it serves as a fuel and also provides the carbon needed for the process. Sahajwalla has found that she can use the rubber in tires and the carbon in spent coffee grounds to the same effect. Professor Sahajwalla, who recently presented her ideas to the Royal Society in London at the Commonwealth Science Conference, said: "Think of ... all the coffee grounds that are produced. That's waste that's left over. And the only thing you do with it is compost it. I thought we could do something better." Steelmakers in Australia are already using an early version of her technique, polymer injection technology, which has reduced the need for coke by 50 percent by using tires.CO2 emissions fell by 80%

But now Sahajwalla has published a paper in the journal "Resources, Conservation & Recycling" showing that it is possible to completely eliminate coke by using coffee grounds. In their original technique, tires were placed in a high-temperature arc furnace at 1550 degrees Celsius. The tires contributed carbon and hydrogen to the process.

"The hydrogen allows us to convert the iron oxide into iron, which then becomes steel," she said. "But we found that we still needed quite a lot of coke. We could only reduce it by about 50% because we still needed the solid carbon for the whole reaction, which rubber couldn't provide by any means."

Professor Sahajwalla, who grew up in Mumbai where every bit of trash and waste is seen as a commodity, said this inspires her approach. When labor is cheap, as it is in India, it may make economic sense. After 100 years of cars, no real solution has yet been found for the disposal or recycling of old car tires. In this respect, the professor's ideas are very welcome. But coffee grounds? There are already uses for them to improve soil quality. And unlike tires, they decompose by themselves after about a year.

"It's about making money, but also about sustainability. Why recycle a tire to bring it back as a tire? Why not reduce it at a molecular level and turn it back into something useful?"

Source: Biswal et al. https://doi.org/10.1016/j.resconrec.2020.105067

Address of the author

Dr. Anselm T. Kuhn,

c/o Metal Finishing Service Ltd,

105 Whitney Drive,

Stevange, Herts,

SG14BL/England;

E-mail:

Editor's note: The political content printed in the "Letter from England" does not necessarily reflect the views of the publisher and editors, but is the personal opinion of the author.