FROC coatings

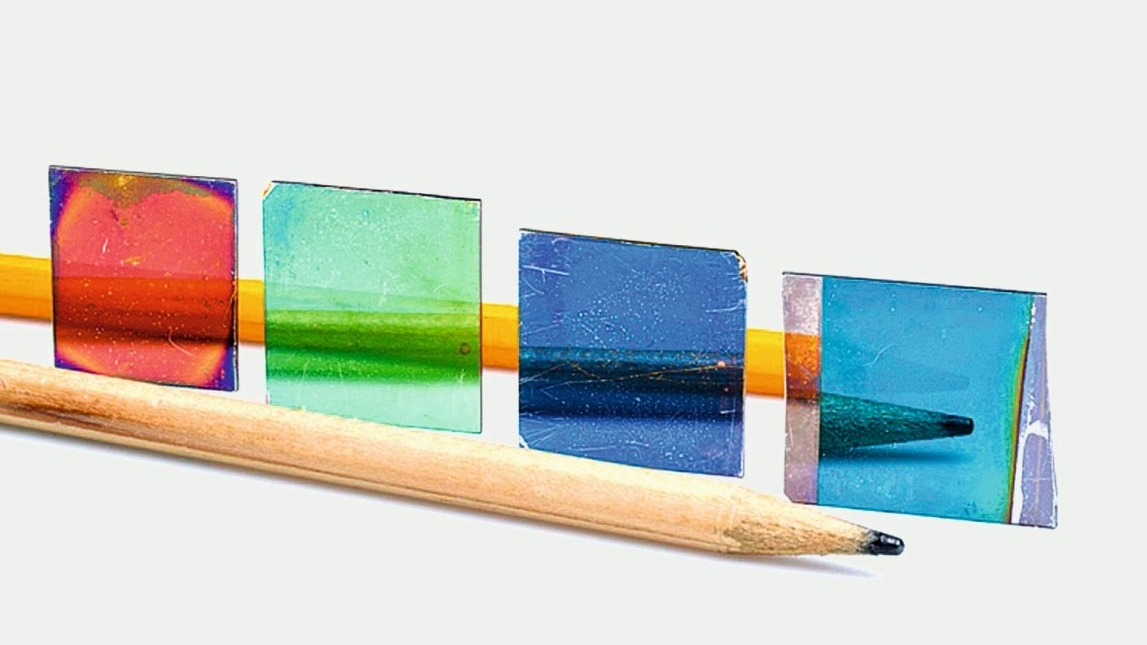

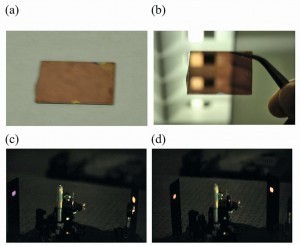

We are all familiar with anti-reflective lenses. Normally, anti-reflective coatings consist of several nanometer-thin layers of magnesium fluoride vapor-deposited onto the lens. The superimposition of several layers practically blocks out certain light waves, for example blue light and UV light. Until now, it has not been possible to develop an optical coating capable of simultaneously reflecting and transmitting the same wavelength or color.

FROC as a beam-splitter filter Scientists from the Universities of Rochester and Case Western Reserve in the USA, led by Prof. Chunlei Guo, have jointly developed a new class of optical coatings that can both reflect and transmit wavelengths of very high purity. A 15 nanometer thick film of germanium was deposited on a metal surface. This film was able to absorb different wavelengths. Special cavities were created to support the resonance. The coupled cavities are able to exhibit Fano resonance in a very narrow wavelength range.

FROC as a beam-splitter filter Scientists from the Universities of Rochester and Case Western Reserve in the USA, led by Prof. Chunlei Guo, have jointly developed a new class of optical coatings that can both reflect and transmit wavelengths of very high purity. A 15 nanometer thick film of germanium was deposited on a metal surface. This film was able to absorb different wavelengths. Special cavities were created to support the resonance. The coupled cavities are able to exhibit Fano resonance in a very narrow wavelength range.

The newly developed optical coatings are called Fano Resonance Optical Coatings (FROCs), after the Italian physicist Ugo Fano. At Fano resonance, asymmetric line shapes occur due to the resonance effect in both photoelectron spectroscopy and inelastic electron scattering on gases. Prof. Guo's lab is known for pioneering research in the field of surface modification of metals using femtosecond laser etching.

With FROC, new surface structures are generated without laser etching. In addition, the reflected light has a narrow wavelength range, in contrast to dielectric mirrors.

One of the intended applications of FROC technology is the separation of thermal and photovoltaic wavelengths of the solar spectrum, which is of great relevance to the photovoltaic industry. In initial studies, a solar device was able to demonstrate up to 50 % energy generation and low photovoltaic temperatures of around 30 °C.

Nature Nanotechnol. 2021, https://doi.org/10.1038/s41565-020-00841-9

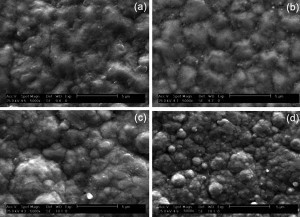

Pulsed current coating of Ni/nano-SiC

Co-coating of silicon carbide nanoparticles from a nickel sulfamate bath under pulsed current conditions was investigated jointly by scientists in Esfarayen and Tehran, Iran. The bath consisted of nickel sulfamate, nickel chloride and boric acid. The average diameter of the SiC nanoparticles was 40 nm. The pH value was set to 4.0 and the tests were carried out at 50 °C. The influence of current density, duty cycle and pulsed waveform was investigated.

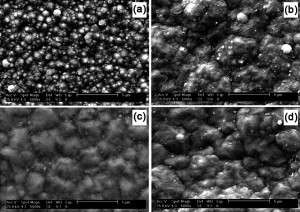

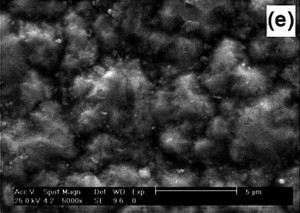

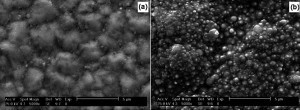

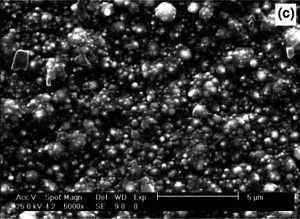

SEM image of the coatings at duty cycle (a) 10 %, (b) 30 %, (c) 50 %, (d) 70 % and (e) 100 %.

It was observed that the grain structure is strongly influenced by the pulsed waveform and the duty cycle. An optimized SiC co-coating of 3.3% by weight was found at a duty cycle of 30%. The Ni-SiC coating with a fine grain microstructure exhibited higher microhardness.

Indian J. Eng. Mater. Sci. 2020, 27, pp. 802-807

SoftSeal Plating Rotor

SoftSealElectroplating RotorTheSolstice Electroplating System from ClassOne has been further modified with the SoftSeal Plating Rotor. The current distribution on the silicon wafer is improved with the help of the rotor and the layer thickness is thus controlled fairly precisely. In addition, the electrolytes are separated from the electrical contacts.

SoftSealElectroplating RotorTheSolstice Electroplating System from ClassOne has been further modified with the SoftSeal Plating Rotor. The current distribution on the silicon wafer is improved with the help of the rotor and the layer thickness is thus controlled fairly precisely. In addition, the electrolytes are separated from the electrical contacts.

The well-known principle of rotating disk electrodes was used in the development of the SoftSeal Plating Rotor. An optimized current density around the silicon disc ensures the quality of the coating. FFKM perfluoroelastomer seals are used to mask and separate the liquid from the edge areas. The new rotor adjusts to the substrate layer thickness. Flat and multi-flat wafers can be coated. An insertion of the rotor without air bubble development is also guaranteed. Of course, the excess electrolyte is fed back into the system.

ADDRESS OF THE AUTHOR

Dr. Nagaraj N. Rao, RRR Labs Pvt. Ltd, RRR House,

Plot 80, Sector 23, Turbhe, CIDCO Industrial Area,

Navi Mumbai - 400 705 India;

E-mail: