Change through trade? No way

In Russia, the word "war" is banned and can be punished with imprisonment. Only the expression "special military operation" is permitted. Intelligent Russians have now realized that freedom of expression (and peaceful demonstrations) are no longer allowed in their country. Perhaps this is one reason why tens of thousands of mainly highly qualified Russians are said to have left their country in the meantime. When they come to Europe, we should welcome them. At the beginning of February, President Putin repeatedly denied that he would invade Ukraine. The intelligence services in the USA did not believe him - and they were right. The French secret service was less fortunate - it believed Mr. Putin's assurances. The French General Vidaud, who headed the secret service, has now been dismissed! Do we know who invented the phrase "change through trade"? How wrong were those who believed it. Now everyone is trying to understand what President Putin thinks and what his plans are. Much of what he has said is ridiculous. He has referred to Ukrainians as "our Slavic brothers" and implied that Ukraine is not an independent country, but in fact a part of Russia. So why is he doing his best to destroy the homeland of millions of his "Slavic brothers"? He claims that Ukraine is ruled by Nazis - with a Jewish president! He claims that the Ukrainian government committed genocide (before the war) but can't prove it. I think his original plan was to annex all of Ukraine. Now he might just want to annex the Donbass (for now), like he did with Crimea in 2014. And while he bombs and shells Ukrainian homes, schools and hospitals, he threatens that any Ukrainian attack on Russian soil will have "the most severe consequences". In other words, a new kind of war with new "rules" in which an attack is permitted but a counter-attack is forbidden. Would he be prepared to use tactical nuclear weapons? I'm afraid it would be foolish to rule this out.

I think President Putin is in a state of cold rage: his plans have not gone well. The West has imposed comprehensive sanctions. The Russian people are feeling the effects of his war. We know that he has dismissed more than 50 members of his secret service, and a high-ranking general has even been arrested.

On paper, Russia had the largest military in the world after the USA and China. But in recent months it has shown alarming weaknesses. Around 600 tanks have been destroyed, many of them by a new generation of portable anti-tank missiles. An estimated 15,000 Russian soldiers have been killed and many more wounded. The cruiser "Moskva" was sunk, most likely by Ukrainian "Neptun" anti-ship missiles. Although the ship was an "old lady" - 40 years old - it was equipped with a whole range of ultra-modern missiles. Theoretically, they should have been able to fend off an attack by these Neptune missiles. So what went wrong? Military experts in the West are analyzing the performance of the Russian attackers - and are not impressed. Only one thing is certain: apart from perhaps a few Russian-speaking people in the Donbass, Ukrainians will passionately hate Russia for generations to come. The war has already cost Russia an enormous loss of life and many billions in military equipment - tanks, helicopters, ships and more. The cost to Ukraine, not only in this regard, but also in terms of civilian buildings, private homes, hospitals, bridges, etc. is already in the hundreds of billions and rising daily. It is clear that Russia should pay the "reparations" - but will it?

On the way into space

Fig. 1: NASA's new centrifugal rocket for satellitesInthe next few years, not hundreds but thousands of satellites are to be launched into low-Earth orbit. According to current plans, they will all be launched into space on board a liquid or solid rocket, usually a multi-stage rocket. This is both expensive and harmful to the environment, as large amounts ofCO2 are emitted. I know of only one alternative, Virgin Intergalactic (what a pompous name!), which uses a jet plane to fly its spacecraft up to an altitude of about 16 km, where the vehicle detaches from the plane and ignites its own rocket engine. But now NASA, in collaboration with a private partner, is planning a completely new approach.

Fig. 1: NASA's new centrifugal rocket for satellitesInthe next few years, not hundreds but thousands of satellites are to be launched into low-Earth orbit. According to current plans, they will all be launched into space on board a liquid or solid rocket, usually a multi-stage rocket. This is both expensive and harmful to the environment, as large amounts ofCO2 are emitted. I know of only one alternative, Virgin Intergalactic (what a pompous name!), which uses a jet plane to fly its spacecraft up to an altitude of about 16 km, where the vehicle detaches from the plane and ignites its own rocket engine. But now NASA, in collaboration with a private partner, is planning a completely new approach.

NASA has signed an agreement with California-based startup SpinLaunch(www.spinlaunch.com) to test its unusual new concept of "whirl and hurl" space technology, in which a launch vehicle is accelerated to hypersonic speeds using an electric centrifuge and hurled into the sky like a space disk. Figure 1 shows the new device.

The system is designed to make launching satellites into low Earth orbit more affordable and environmentally friendly. SpinLaunch has been testing its system in the New Mexico desert for several months and even conducted its first successful test in October 2021, launching a 3-meter-long projectile to an altitude of tens of thousands of meters. In a statement, the company explained that its futuristic A-33 Suborbital Mass Accelerator works like a "slingshot".

The test flight, which is due to take place later this year, will provide NASA with valuable information for potential future commercial launch opportunities, SpinLaunch said. The "kinetic" launch system, considered an environmentally friendly alternative to propellant launches, works by attaching a reusable rocket to a giant rotating arm in an electric, vacuum-sealed centrifuge and spinning it at several times the speed of sound. The rocket is then released and launched into space to carry payloads such as small satellites into low Earth orbit. The giant slingshot is located at Spaceport America in New Mexico. It is slightly larger than the Statue of Liberty. While NASA plans to test the extraordinary machine later this year, SpinLaunch aims to make its first test flights into orbit in 2025. If this technology is successful, it could make European, Russian and other commercial satellite launch companies redundant.

Into space - but why?

As I mentioned, there are plans to launch thousands of satellites into low-Earth orbit. But for what purpose? The vast majority will be used for communication, the internet, telephone calls and information transfer. Then there are cameras and other sensors for monitoring the earth's surface, climate and weather and, of course, military satellites, which have never been more important in view of the "special military operations" in Ukraine, and every year the cost of launching satellites is decreasing. In the 1980s, launching into space could cost up to $35,000/kg. Today, payloads on Elon Musk's rockets cost $1000 to $3000/kg, and his new 130-meter spacecraft is expected to bring those costs down even further. If the SpinLaunch technology is successful, these figures will drop even further. Are there any other applications that could be interesting for space technology? Many experts believe that the production of new materials that are suitable for conditions of weightlessness, microgravity and temperatures close to absolute zero would have a great future. This idea is not new. In the 1970s, this was used to produce semiconductors on the Skylab space station. Ceramic turbine blades for airplanes were also produced with the aim of eliminating microscopic defects through gravity.

A relatively new company in Wales, SpaceForge, was founded to exploit the potential of space as a manufacturing environment. Their first satellite. ForgeStar-0 is due to be launched from Cornwall in the west of England in a few months' time. It will be the first space launch in England for around 50 years. The Virgin launch system already described will be used. ForgeStar-0 is the prototype of a space laboratory. Its purpose is to test the heat shield that will protect the new materials produced there from the heat when the spacecraft re-enters the Earth's atmosphere. Figure 2 gives an impression of this first Space Forge satellite, which will only be about 1m3 in size. However, future versions could be the size of a small car. What developments does the company have in mind? That's largely confidential, but semiconductors seem to be a theme, along with new alloys and 3D-printed products that can be manufactured in zero gravity in a way that's impossible on solid ground. No doubt the US, China and others will have their own plans. This is a new era of manufacturing.

After 1100 years

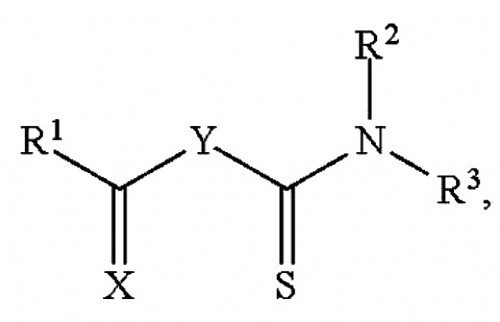

Fig. 3: General formula of Excir precious metal extraction solventTheBritish Royal Mint is one of the oldest in the world, perhaps even the oldest. It was founded 1100 years ago and still mints coins in gold, silver and cupronickel not only for the UK, but for dozens of other countries around the world. But cash is slowly disappearing as more and more electronic transactions are used. For many years, the Royal Mint also produced special coins and medals, usually in 22-carat or even higher-grade gold, mainly as an investment. But in recent months, the Mint has launched a new project. Together with the Canadian company Excir (www.exir.com), it is building a new plant to recover precious metals from so-called "e-waste" - electronic scrap. It is estimated that around 50 million tons of electronic scrap are produced worldwide. According to experts, less than 20% of this is recycled, the rest is simply buried with other waste. The value of this buried electrical waste is estimated at around 57 billion US dollars, a truly staggering sum. And yet, everyone agrees that recovering precious metals from cell phones, laptops and their circuit boards is not easy. A typical cell phone contains about 0.04 grams of gold worth about 2 euros; a typical laptop contains about 0.1 grams of gold. Old cell phones and laptops are usually dismantled first, with some components - e.g. screens - being recycled. The circuit boards are then mainly sent to Germany, the Netherlands and Thailand. In most cases, they are treated in high-temperature processes from which the gold and other precious metals are recovered. Such high-temperature processes are both expensive and harmful to the environment. Excir, on the other hand, has developed an aqueous low-temperature process that will be used in this new joint venture.

Fig. 3: General formula of Excir precious metal extraction solventTheBritish Royal Mint is one of the oldest in the world, perhaps even the oldest. It was founded 1100 years ago and still mints coins in gold, silver and cupronickel not only for the UK, but for dozens of other countries around the world. But cash is slowly disappearing as more and more electronic transactions are used. For many years, the Royal Mint also produced special coins and medals, usually in 22-carat or even higher-grade gold, mainly as an investment. But in recent months, the Mint has launched a new project. Together with the Canadian company Excir (www.exir.com), it is building a new plant to recover precious metals from so-called "e-waste" - electronic scrap. It is estimated that around 50 million tons of electronic scrap are produced worldwide. According to experts, less than 20% of this is recycled, the rest is simply buried with other waste. The value of this buried electrical waste is estimated at around 57 billion US dollars, a truly staggering sum. And yet, everyone agrees that recovering precious metals from cell phones, laptops and their circuit boards is not easy. A typical cell phone contains about 0.04 grams of gold worth about 2 euros; a typical laptop contains about 0.1 grams of gold. Old cell phones and laptops are usually dismantled first, with some components - e.g. screens - being recycled. The circuit boards are then mainly sent to Germany, the Netherlands and Thailand. In most cases, they are treated in high-temperature processes from which the gold and other precious metals are recovered. Such high-temperature processes are both expensive and harmful to the environment. Excir, on the other hand, has developed an aqueous low-temperature process that will be used in this new joint venture.

Excir's technology is described in patents US20180112289A1 - Process for selective leaching and extraction of precious metals in organic solvents and US20180142322A1 (with the same title).

In the process at room temperature, an organic solvent which is miscible with water or partially miscible with water is used together with an acid and an oxidizing agent to extract gold or platinum group metals (mainly Pt and Pd). After removing the solid impurities, the solvent is evaporated and the remaining solids are treated with a second solvent, the general formula of which is shown in Figure 3, with various organic groupings indicated. Metallic gold/platinum/palladium can then be recovered by conventional electrowinning or chemical reduction using thiourea.

The new plant in Wales has an initial capacity of 90 tons of e-scrap per week - i.e. around 7 to 9% of UK e-scrap - and, if all goes well, will be expanded further. An exciting new era ?

Electric boats

Every day we hear news about electric cars. There are also many exciting developments in electric airplanes. But there is less news about electric boats. Candela, a Swedish company with close ties to the USA, has developed a remarkable series of electric hydrofoils. Thanks to the hydrofoil effect, which lifts the hull completely out of the water, these boats are extremely energy efficient and run completely silently at high speeds - up to 30 knots. At a speed of more than 16 knots, the boat begins to "fly" and lifts itself above the water on its "wings". At a speed of 22 knots, the energy consumption is only 0.8 kWh/nautical mile. The hull is made of carbon fiber. Figure 4 shows the so-called C8 and Figure 5 the propulsion nacelle with two permanent magnet electric motors that operate underwater and are connected to the hull via the strut. The electric motors have an output of 45/59 kW. The company manufactures a range of electric boats, with the C8 being able to carry eight people.

Despite the war, life goes on

Despite the terrible headlines from Ukraine, amazing progress continues to be made in the world of science, medicine and technology. The Covid pandemic has led to huge investment in vaccine production, as well as the development of improved vaccines for other infectious diseases. I have previously reported on new methods of food production, including so-called "vertical farms". Do you like caviar? The best caviar, Oscietra Caviar, costs about 320 euros for 125g, and no, I wasn't wrong. Caviar used to come from sturgeons in the Caspian Sea. Today, China is the world's largest producer, with hundreds of "caviar farms" where the sturgeons are kept in large tanks. Female Siberian sturgeon take 4 to 5 years to develop their eggs, which are the basis for caviar. In a small facility in Devon, England, a new company, Caviar Biotec (caviarbiotec.com), has successfully grown caviar eggs from single cells in vitro. The patented process can produce caviar in just 40 days. And the company believes it can produce enough caviar in a laboratory of around 300m2 to meet most of the current world demand, including various oils extracted from the eggs, for which many medical claims are made. Of course, "real caviar" will always have a higher price - just as sparkling wine is cheaper than French Premier Cru Champagne. Is this price premium worth it? Everyone has to decide for themselves. Cheers!

In California, another new company, Cana (www.cana.com), has come up with a truly revolutionary idea. The average American household consumes about 2500 bottles or cans of beverages per year. About 98 or 99% of their content is water. And after use, these 2500 bottles or cans need to be recycled. But in most cases, they are simply thrown away in the garbage can. Around 1 trillion beverage bottles and cans are sold worldwide, most of which are never recycled. So Cana has invented a microwave-sized machine that can make 500 different drinks including coffee, tea, hot or cold carbonated or still drinks and even red wine, but sadly not white wine. The entry machine, Cana One, is shown in Figure 6. Critics will call the technology "fake" or a "poor imitation". However, the technology behind the machine is similar to that of an inkjet printer. The machine is equipped with a series of cartridges, each containing a substance found in our everyday drinks. The selected drink is then produced by injecting a certain number of these ingredients into water. Journalists who were shown the machine and tasted some of their drinks, such as iced coffee, were pleasantly surprised. The planned cost of the machine is around 800 US dollars, which I think is reasonable. How did the idea come about? The invention goes back to the work of a German scientist, Professor Thomas Hofman from the University of Munich. In 2011, he used chromatography to isolate around 60 molecules that make up the taste and smell of red wine and published the results. The technologists at Cana have built on his work. Users can now select the drink of their choice using a keyboard and screen.

Basic science

A civilized society is characterized by its willingness to spend money to acquire new knowledge out of intellectual curiosity. This is the basis of archaeology, the study of ancient music - and basic science. Will a deeper understanding of fundamental particle physics improve our lives? It is unlikely, and yet it could have an interesting side effect in the future. After an extensive three-year upgrade, CERN's giant Large Hadron Collider (LHC), the world's most advanced accelerator, will resume operations 100 meters below the surface on the French-Swiss border.

The aim is to improve our knowledge of the fundamentals of matter. Only one of the four particle detectors, the Atlas detector, is 46 meters long and 25 meters high. It consists of 7,000 tons of metal, silicon, electronics and cables. Figure 7 shows the assembly hall of the magnet.

This gigantic project may not have an immediate impact, but valuable lessons are being learned in building large electromagnets - and large and powerful magnets may be a key to the future of nuclear fusion.

A new fleet of hydrogen buses

In a few months, multinational public transportation company Go-Ahead will launch its first fleet of hydrogen fuel cell buses. The fleet of 20 buses, the largest in Europe, will be built in Northern Ireland by Wrightbus. The hydrogen will be supplied by US giant Air Products under a 15-year contract and will be produced and liquefied at wind farms in the Netherlands before being transported to the UK. At present, these fuel cell buses cost around twice as much as conventional diesel buses, but the British government is subsidizing their sustainable purchase. The Scottish company Alexander Dennis also manufactures fuel cell buses, of which Go-Ahead could purchase a further tranche. The new buses will be used in and around Gatwick Airport. Figure 8 shows the latest double-decker fuel bus from Wrightbus.