People on the move

The topic of migration is not new. Many Germans carry the genes of the Roman soldiers who conquered large parts of Europe almost 2000 years ago. The same applies to the English, who were also conquered first by the Romans and then by the Vikings. In both cases, many of the invaders decided to settle in Germany or England and married local women.

At the end of the 17th century, around 50,000 Huguenots fled to England to escape persecution in France. Towards the end of the Second World War and in the years that followed, there was a large influx of people from the East to Germany. It was only in the following decades, roughly between 1950 and 2010, that the pace slowed down. But in recent years, we have experienced mass migration like never before, with millions of people on the move. Sometimes these migrants are driven by the search for a better life. Sometimes they are refugees fleeing war. No one knows this better than Germans, who in 2015 witnessed the immigration of over a million refugees from the Middle East, most of whom ended up in Germany, famously commented on with Angela Merkel's famous words "Wir schaffen das" ("We can do it").

2015 may have been the peak, but the flood of migrants has continued. They come from Africa, Pakistan, Bangladesh, Afghanistan and other countries. Some come as families, some as single young men, some are even unaccompanied children. There are young men who tell lies about their age and pretend to be children, and the doctors then have to decide who is telling the truth or not. Spain can hardly prevent illegal migration to its two Moroccan enclaves Ceuta and Melilla. The same applies to the Canary Islands, around 300 km from the West African coast. For the whole of 2021, it is predicted that almost 10,000 people will illegally cross the Channel to England in small rubber dinghies, a record number. In Afghanistan, NATO has failed to stop the Taliban and has now withdrawn. Around 10,000 Afghans who acted as interpreters now face death and the US will take them and their families in as immigrants. Donald Trump failed to build his so-called "beautiful wall" on the southern border with Mexico, and illegal immigration reached its highest level in 20 years in May, almost 200,000 in just one month.

Meanwhile, there is a shortage of around 70,000 truck drivers and around 100,000 doctors and nurses in England. Brexit caused many European citizens to leave England and return to their home countries. Brexit allowed the British government to estimate the number of EU citizens living in the UK. They thought it was around 3.5 million, but it was actually 5.4 million. So England had around 2 million more inhabitants that it didn't know about! In today's Europe, Italy (approx. 60 million inhabitants) has a so-called "fertility rate" of 1.3 children per couple. The fertility rate required to maintain the population is 2.1 children per couple. A steady decline in the population is therefore forecast for Italy in the coming years. Similar predictions are made for France (approx. 1.9 children), Germany (approx. 1.6) and the UK (approx. 1.7). So what are we to make of such statistics? We are concerned about global warming - but it's not because ofCO2 or methane emissions - it's because of the people causing those emissions. In terms of climate change, a shrinking population is desirable.

Fig. 1: Estimated percentage of existing jobs at risk from automation (courtesy of PWC)

Fig. 1: Estimated percentage of existing jobs at risk from automation (courtesy of PWC)

Then we have the issue of job losses due to AI and automation. There are many predictions for these effects. One of them is shown in Figure 1, based on a study of 29 countries worldwide*. All the experts agree that the pandemic has accelerated the pace of automation, along with low interest rates that favor investment.

Fig. 2: The Belarusian government escorts "tourists" from Turkey to the EU border in LithuaniaCriminalshave not been slow to make money out of would-be migrants, and thousands who cross the Channel illegally pay around €5,000 per person to such criminal gangs. But in recent months we have seen something completely new - state crime. The government in Belarus organizes "tourist flights" from Turkey to Minsk. As soon as these "tourists" arrive, they are escorted to the Lithuanian border, where they try to enter Lithuania - and thus the EU. Lithuania is now desperately building border fences (Fig. 2).

Fig. 2: The Belarusian government escorts "tourists" from Turkey to the EU border in LithuaniaCriminalshave not been slow to make money out of would-be migrants, and thousands who cross the Channel illegally pay around €5,000 per person to such criminal gangs. But in recent months we have seen something completely new - state crime. The government in Belarus organizes "tourist flights" from Turkey to Minsk. As soon as these "tourists" arrive, they are escorted to the Lithuanian border, where they try to enter Lithuania - and thus the EU. Lithuania is now desperately building border fences (Fig. 2).

Where will this whole story end? President Trump planned to prevent illegal migration by building a wall along the approximately 3000 km long border with Mexico. In the end, he managed to build or renew about 700 km. President Biden has not yet decided what he wants to do about the problem. In Australia, all illegal immigrants are now being sent to a camp on the islands of Papua New Guinea. In Europe, it is Denmark that has the strictest policy on migration and asylum seekers, and now that Damascus is labeled "safe", Denmark is planning to send thousands of Syrians back to their home country.

Global warming and uncontrolled population growth will make life in Africa worse for hundreds of millions of people there, driving them to migrate to Europe. Governments in all countries must now make tough decisions. The Huguenots were fleeing persecution. Most migrants today are simply fleeing war or looking for a better life. We should have compassion for them, but there are billions in Africa alone who could make a similar claim. It would be impossible for Europe or the US to take in such numbers. And it is a sad fact that the more such migrants arrive, the more they urge their family and friends to join them. Denmark will be criticized for its tough new policy. But is there an alternative? Is it still true, this "We can do it!"?

*https://www.pwc.co.uk/services/economics/insights/the-impact-of-automation-on-jobs.html

On the road to a hydrogen economy

We seem to be moving steadily towards a hydrogen economy. Hydrogen, whether "blue" or "green", is needed in industry, transportation and the home.

The latest news concerns a massive hydrogen storage project. According to plans by energy company SSE and Norwegian state-owned Equinor, one of the UK's largest natural gas storage facilities could be converted to store hydrogen. The two companies jointly own the facility in Aldbrough (East Yorkshire), which was commissioned in 2011 and stores natural gas in nine underground salt caverns. The companies have announced that they are now working on plans to either convert the site to store hydrogen or develop new hydrogen storage caverns alongside the existing facilities.

The hydrogen storage facility will initially be used to supply the world's first hydrogen-fired power station planned by the companies at Keadby in North Lincolnshire. The conversion project at Aldbrough is expected to cost hundreds of millions of euros and is dependent on policy measures from the UK government to make it financially viable. The facility would be far larger than any existing hydrogen storage facility in the world and is expected to be one of the largest in the world once operational, which the companies say could be by 2028. The site represents around 17% of the UK's gas storage capacity, following the closure of energy company Centrica's huge Rough storage facility in the North Sea in 2017. Centrica is now also pursuing plans to convert Rough to store hydrogen at a cost of €1.8 billion, again dependent on political support to make this viable.

SSE and Equinor's plans for Aldbrough are part of a wider strategy to develop new hydrogen infrastructure in the Humberside region of England on the North Sea coast. Equinor plans to develop facilities that produce low-carbon 'blue' hydrogen from natural gas, capture carbon dioxide emissions and store it offshore, below sea level. Equinor and SSE are also jointly planning to build the world's first large-scale pure hydrogen combustion power plant in Keadby, which could generate enough electricity to power a million homes.

From MegaWatt to MilliWatt

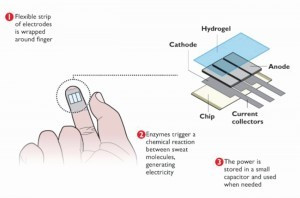

Fig. 3: Enzyme-containing "patches" generate electricity Our cell phones are getting smarter and smarter, but we still have to charge them when the battery is empty. Now a new idea is being tested. Scientists have developed a wearable device that can collect sweat from your fingers and convert it into energy. The flexible, plaster-like strip contains harmless enzymes that react with chemicals in human sweat to generate electricity and then store it. Researchers at the University of California San Diego (UCSD) found that when worn overnight for ten hours, the device collects nearly 4 joules of energy - enough to power an electronic wristwatch for 24 hours. If strapped to each finger (Fig. 3), such a device would generate ten times as much energy, raising the prospect that larger, more complex electronic devices could also be powered by sweat. However, the researchers cautioned that in its current form, it would take three weeks to generate enough energy to fully charge a smartphone. They hope that the invention could prove useful in health technology, for example as a sensor to measure blood sugar levels in diabetics. Previous devices that rely on sweat for energy require the user to engage in intense physical activity, such as lots of running or cycling, before anything can be powered.

Fig. 3: Enzyme-containing "patches" generate electricity Our cell phones are getting smarter and smarter, but we still have to charge them when the battery is empty. Now a new idea is being tested. Scientists have developed a wearable device that can collect sweat from your fingers and convert it into energy. The flexible, plaster-like strip contains harmless enzymes that react with chemicals in human sweat to generate electricity and then store it. Researchers at the University of California San Diego (UCSD) found that when worn overnight for ten hours, the device collects nearly 4 joules of energy - enough to power an electronic wristwatch for 24 hours. If strapped to each finger (Fig. 3), such a device would generate ten times as much energy, raising the prospect that larger, more complex electronic devices could also be powered by sweat. However, the researchers cautioned that in its current form, it would take three weeks to generate enough energy to fully charge a smartphone. They hope that the invention could prove useful in health technology, for example as a sensor to measure blood sugar levels in diabetics. Previous devices that rely on sweat for energy require the user to engage in intense physical activity, such as lots of running or cycling, before anything can be powered.

This breakthrough achieves what researchers are calling the "holy grail" of energy-gathering gadgets, as it does not require exercise or any external, irregular sources of power. The device also generates energy when pressure is applied to it, i.e. during activities such as typing on a keyboard.

Fig. 4: Functional diagram of the new device (courtesy of Tom Knowles)Joseph Wang, a professor of nanoengineering at UCSD and co-author of the study, said, "We wanted to create a device that is adapted to daily activity and requires almost no energy investment. You can forget about the device and go to sleep or do desk work like typing and still continue to generate energy. You can call it 'energy from doing nothing'." The researchers said that while it may seem strange to record sweat from the fingers and not, say, the armpits, the fingertips actually have the highest concentration of sweat glands on the body. They each have more than a thousand sweat glands and can produce between 100 and 1000 times more sweat than most other parts of the body. "Producing more sweat on the fingers probably evolved to help us grip things better," says Lu Yin, a nanotechnology PhD student in Wang's lab and a co-author of the report. "The amount of sweat on the finger can be up to a few microliters per square centimeter per minute. That's significant compared to other parts of the body." The reason why we sweat more on other parts of the body is that these areas are not well ventilated. In contrast, the fingertips are always exposed to the air, so the sweat evaporates when it comes out. So instead of letting it evaporate, you use the device to collect that sweat, and that can generate a significant amount of energy.

Fig. 4: Functional diagram of the new device (courtesy of Tom Knowles)Joseph Wang, a professor of nanoengineering at UCSD and co-author of the study, said, "We wanted to create a device that is adapted to daily activity and requires almost no energy investment. You can forget about the device and go to sleep or do desk work like typing and still continue to generate energy. You can call it 'energy from doing nothing'." The researchers said that while it may seem strange to record sweat from the fingers and not, say, the armpits, the fingertips actually have the highest concentration of sweat glands on the body. They each have more than a thousand sweat glands and can produce between 100 and 1000 times more sweat than most other parts of the body. "Producing more sweat on the fingers probably evolved to help us grip things better," says Lu Yin, a nanotechnology PhD student in Wang's lab and a co-author of the report. "The amount of sweat on the finger can be up to a few microliters per square centimeter per minute. That's significant compared to other parts of the body." The reason why we sweat more on other parts of the body is that these areas are not well ventilated. In contrast, the fingertips are always exposed to the air, so the sweat evaporates when it comes out. So instead of letting it evaporate, you use the device to collect that sweat, and that can generate a significant amount of energy.

The device contains hydrogel to maximize absorption, with the sweat then being absorbed by electrical conductors or electrodes made from a carbon foam. Enzymes on the electrodes trigger a chemical reaction between oxygen and the lactate of the sweat molecules, generating electricity that is stored in a small capacitor within the device, which can then be discharged to provide power for low-power devices.

On track - China leads the world

Fig. 5: The new Chinese high-speed maglev trainAfew weeks ago, China unveiled what could be the world's fastest passenger train, traveling at more than 600 km/h on tracks yet to be built. The new maglev train, which uses magnetic levitation technology to eliminate friction with the rails, comes at a time when Beijing is trying to cement its position as the world's most prolific builder of high-speed rail lines (Fig. 5). The new train rolled slowly out of a shed belonging to the state-owned CRRC, China's official train builder, in the eastern city of Qingdao. "Welcome to the high-speed maglev train traveling at 600 km/h," read a digital screen in one of the cars, according to a video released by the official Xinhua news agency.

Fig. 5: The new Chinese high-speed maglev trainAfew weeks ago, China unveiled what could be the world's fastest passenger train, traveling at more than 600 km/h on tracks yet to be built. The new maglev train, which uses magnetic levitation technology to eliminate friction with the rails, comes at a time when Beijing is trying to cement its position as the world's most prolific builder of high-speed rail lines (Fig. 5). The new train rolled slowly out of a shed belonging to the state-owned CRRC, China's official train builder, in the eastern city of Qingdao. "Welcome to the high-speed maglev train traveling at 600 km/h," read a digital screen in one of the cars, according to a video released by the official Xinhua news agency.

The train will go into operation in five to ten years, officials said. For now, the five-car train can hover "steadily" and operate "dynamically," according to a state news site, and it provides "the most convenient means of transportation for travel within a 1500-kilometer radius." China already operates the world's most extensive network of high-speed trains on more than 39,000 kilometers of track. The trains normally travel at 200 to 350 km/h, but the country wants to develop a train model that can travel almost twice as fast.

The high-speed maglev train will be suspended, propelled and guided without contact between the train and track using electromagnetic forces, with the only resistance coming from the air. Beijing said the maglev train could bridge the gap between high-speed trains, which are normally limited to about 300 km/h, and commercial airplanes, which fly at about 800 km/h. State media said the 1300-kilometer journey from Beijing to Shanghai takes about two hours by plane, five and a half hours by high-speed rail and just two and a half hours by high-speed mag- netic train. China's maglev project began in 2016. By 2019, CRRC had built a prototype and conducted a successful test run a year later. Now CRRC has built a complete system and is one step closer to commercial operation - even though the country has not yet built any commercial tracks for the train to run on. State media praised the new train as the beginning of the country's "post-high-speed era". This came several months after Beijing unveiled an ambitious plan for the country's future transportation system, which included the development of "three-hour transportation circles" between the largest cities.

The eastern province of Zhejiang has presented a 12 billion euro plan to build a maglev train with a design speed of 600 km/h. Two other provinces have similar plans. Two other provinces have similar plans. Beijing also wants to become a major exporter of high-speed railroads as part of President Xi's flagship Belt and Road Initiative, which aims to expand the country's global footprint through massive infrastructure construction. China now has three maglev lines, the fastest of which runs at 430 km/h in Shanghai using German technology. The other two lines are much slower, running at only 100 and 120 kilometers per hour.

Germany and Japan are also developing maglev trains, but it seems that China is currently ahead in this technology, as in so many others. We should be worried.

Two problems - one solution

Fig. 6: Shredded plastic has a sand-like morphology (courtesy of Dr. John Orr) Plastic waste is a growing problem in almost every country in the world. There are many photos of rivers in Asia clogged with plastic waste. In India, an estimated 15,000 tons of plastic are thrown away every day. Some of the plastic can be recycled, but it is not always economical to do so. Most readers will already be aware of this. But how many readers are aware of another problem - the lack of sand? Sand is plentiful on every seashore - but because it contains salt, it is not suitable for making concrete. The Sahara Desert is a vast expanse of sand, but the morphology of the sand grains (almost no sharp edges), also makes it unsuitable for concrete. The best sand for making concrete is dredged from river beds, but here too there are problems. Because of such shortages, criminal gangs known as "sand mafias" have entered this market in some parts of the world. A solution, or at least a partial solution to these two problems, has been found by Dr. John Orr of Cambridge University. He has shown that high quality concrete can be made from shredded plastic to replace some of the sand used. Figure 6 shows a sample of shredded plastic, which is not dissimilar in morphology to sand.

Fig. 6: Shredded plastic has a sand-like morphology (courtesy of Dr. John Orr) Plastic waste is a growing problem in almost every country in the world. There are many photos of rivers in Asia clogged with plastic waste. In India, an estimated 15,000 tons of plastic are thrown away every day. Some of the plastic can be recycled, but it is not always economical to do so. Most readers will already be aware of this. But how many readers are aware of another problem - the lack of sand? Sand is plentiful on every seashore - but because it contains salt, it is not suitable for making concrete. The Sahara Desert is a vast expanse of sand, but the morphology of the sand grains (almost no sharp edges), also makes it unsuitable for concrete. The best sand for making concrete is dredged from river beds, but here too there are problems. Because of such shortages, criminal gangs known as "sand mafias" have entered this market in some parts of the world. A solution, or at least a partial solution to these two problems, has been found by Dr. John Orr of Cambridge University. He has shown that high quality concrete can be made from shredded plastic to replace some of the sand used. Figure 6 shows a sample of shredded plastic, which is not dissimilar in morphology to sand.

Test samples of concrete containing plastic (Fig. 7) have shown excellent mechanical properties. It is estimated that this could save 820 million tons of sand per year in India alone. I wonder what readers will think of this idea? True, it is a solution to two major problems. But isn't plastic waste itself much more valuable? Isn't there a better way to recycle it?

Better batteries?

Fig. 7: Concrete samples made with plastic waste (courtesy of Dr. John Orr) In Germany and France, so-called gigafactories are being built to produce lithium batteries for the growing number of EVs, e.g. in Erfurt. Several of these are Chinese, the Erfurt plant owned by Chinese company CATL will be about 3 times the size of the Tesla plant in the US. Naturally, the owners hope that these plants will have a long life and will not be quickly overtaken by newer technologies. The planned UK Gigafactory, which will serve the nearby Nissan plant, will also be Chinese, in this case AESC.

Fig. 7: Concrete samples made with plastic waste (courtesy of Dr. John Orr) In Germany and France, so-called gigafactories are being built to produce lithium batteries for the growing number of EVs, e.g. in Erfurt. Several of these are Chinese, the Erfurt plant owned by Chinese company CATL will be about 3 times the size of the Tesla plant in the US. Naturally, the owners hope that these plants will have a long life and will not be quickly overtaken by newer technologies. The planned UK Gigafactory, which will serve the nearby Nissan plant, will also be Chinese, in this case AESC.

Whether we like it or not, China is pushing into our economies. But are today's lithium batteries the last word? A number of start-ups are developing alternative batteries and in particular solid-state batteries that promise higher energy density and therefore longer range for eVs. One such company is Ilika (www.ilika.com), based in the south of England. The company claims that their solid state batteries have higher energy density, higher power density, higher charge rates, longer storage and cycle life and that they are non-flammable. They target two separate markets: small batteries for medical devices, for example, and large power batteries for eVs. These batteries belong to a family known as "Quantum Glass Batteries", which use a thin film of special glass in which lithium ions are mobile. They are predicted to offer energy densities of 500 Wh/kg or more.

Another start-up company is AMTE Power, based in Scotland (www.amtepower.com). Its technology, also lithium-based, appears to be similar to Ilika's. Another start-up, Faradion (www.faradion.co.uk), based in Sheffield, England, focuses on sodium-ion technology. However, Faradion has teamed up with AMTE and demonstrated that the respective lithium and sodium batteries can be produced on the same production line. Faradion batteries do not contain cobalt or copper, which makes them more cost-effective. Faradion's website contains links to its patents. A sample of its batteries is shown in Figure 8 .

Fig. 8: A selection of sodium batteries (courtesy of Faradion Ltd.) As batteries become more energy dense, thermal management is becoming an increasing problem. Another start-up, Cognition Energy(www.cognition.energy), based near Oxford, England, uses lithium technology but focuses on thermal management. As a result, they communicate a 30,000 cycle life (approx. 10 years) for their batteries, resulting in a 75% reduction in operating costs, as well as fast recharging and easy recycling.

Fig. 8: A selection of sodium batteries (courtesy of Faradion Ltd.) As batteries become more energy dense, thermal management is becoming an increasing problem. Another start-up, Cognition Energy(www.cognition.energy), based near Oxford, England, uses lithium technology but focuses on thermal management. As a result, they communicate a 30,000 cycle life (approx. 10 years) for their batteries, resulting in a 75% reduction in operating costs, as well as fast recharging and easy recycling.

Lithium-air batteries can be considered as hybrid battery-fuel cells. A new type of lithium-air battery recently unveiled by researchers in China combines higher capacity, longer life and greater stability than conventional batteries. The device, which integrates a solid zeolite electrolyte with two electrodes, could represent a significant step towards the feasibility of such batteries for electric vehicles and energy storage.

Lithium-air batteries typically use an anode of pure lithium and a form of porous carbon at the cathode. When the battery is discharged, lithium ions flow from the anode to the cathode where they meet electrons that flow through the external circuit and react with oxygen from the air. When the battery is charged, this process is reversed. As lithium is highly electropositive and extremely light and air is practically massless, lithium-air batteries have the highest theoretical maximum specific energy density of all battery types.

In practice, however, it has proved extremely difficult to develop a viable rechargeable device. The extreme reactivity of lithium is a double-edged sword: it allows the storage of a huge amount of energy, but the controlled, safe and reversible release of this energy is difficult. The early Li-air batteries used different liquid electrolytes. Lithium reacts violently with water, which causes problems in aqueous electrolytes, and organic electrolytes are prone to side reactions.

"The intrinsic thermodynamic instability of lithium leads to continuous and irreversible reactions between the anode and the organic electrolyte, resulting in decomposition of the electrolyte accompanied by corrosion of the lithium metal anode," explains Jijing Xu from Jilin University in Changchun, China. Normally, an ion-conducting separator is inserted to protect the lithium, but placing such a system - especially if it contains a flammable organic electrolyte - in a battery that must be open to the air raises serious safety concerns.

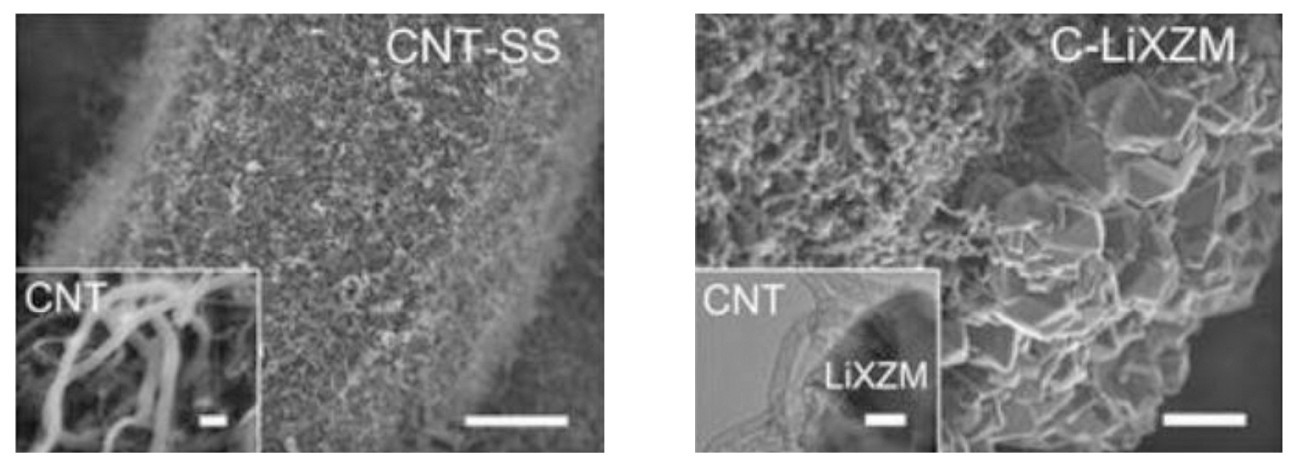

Researchers are therefore increasingly turning to solid electrolytes. However, these come with their own problems: for the battery to work efficiently, the electrolyte material must have a high ionic conductivity and low electrical conductivity and good contact with the lithium electrode to minimize contact resistance. Finally, it should not react with either the lithium or the oxygen when it is electrochemically cycled. The search for such a material has proved difficult. Xu et al. grew nitrogen-doped carbon nanotubes on stainless steel mesh by chemical vapor deposition to form their cathode. (Fig. 9, 10).

Fig. 9: SS = stainless steel, CNT = carbon nanotubes

Fig. 9: SS = stainless steel, CNT = carbon nanotubes

Then they added a highly monocrystalline, 5 μm thick layer of a lithium-containing zeolite to serve as the electrolyte. Finally, they poured molten lithium directly onto the back of this layer to form the anode.

"This is the first integrated cathode/solid electrolyte/anode design for a lithium-air battery," explains Jihong Yu, also from Jilin University, who led the research alongside Xu.

The researchers tested their product against several other types of lithium-air batteries and found it to be superior in several ways. Despite its thinness, the zeolite protected the metal anode from corrosion by oxygen orders of magnitude longer than the commercially available solid-state electrolyte and provided excellent electrical insulation, while being much more conductive to lithium ions. While the cycling stability of many other types of solid-state lithium-air batteries began to deteriorate, sometimes after only 10 charge/discharge cycles, this battery performed at maximum capacity for nearly 150 cycles. At this point, lithium carbonate - which is formed when lithium reacts with the carbon dioxide that forms in a side reaction - began to inactivate the cathode. This is a common problem in lithium-air batteries, Yu explains.

Fig. 10: Carbon nanotubes grown by CVD on a stainless steel mesh (Fig. 9 and 10 courtesy of Chemistry World)

Fig. 10: Carbon nanotubes grown by CVD on a stainless steel mesh (Fig. 9 and 10 courtesy of Chemistry World)

The development ofCO2-selective absorbing or blocking membranes on the surface of the cathode or the research and design of more stable carbon-free cathodes are considered effective ways to reduce the formation of lithium carbonate. The researchers are now working to extend their zeolite membrane design beyond lithium-air batteries to other types of lithium batteries as well as sodium and magnesium batteries and beyond.

Source: X Chi et al. Nature (2021)592, p. 551 (DOI: 10.1038/s41586-021-03410-9)

Conclusion:

In this snapshot, I have tried to show that the lithium batteries we use in our EVs today could be replaced in just a few years by new technology batteries that have higher energy density, longer life and higher charge rates. Does this mean battery technology is mature? The answer is no!