Chris Jentner, owner of the Jentner Group, is having a digitally supported electroplating facility built at the site in Pforzheim. With this multi-million euro project, he is promoting transparency, sustainability and resource efficiency in the company and thus setting it up for the future.

The digitalization of production is no longer a mere declaration of intent, but is increasingly gaining ground in the industry. The networking of machines and systems is progressing and turning companies that were once characterized by craftsmanship and experience into transparent factories that are more attractive for employees and more predictable for operators and customers. Galvanik C. Jentner GmbH, led by managing owner Chris Jentner and production manager Heike Klaus-Karwisch, is also following this path. The Pforzheim-based company is currently preparing for the future by expanding its existing electroplating facility with a new building that meets the latest technical standards.

The gold town of Pforzheim and its heirs

Jentner Managing Director Chris Jentner expects the electroplating industry to develop at two speeds in future. Those who digitize their production will make faster progress than those who do not . While the new building is still waiting to be completed next autumn with scaffolding, the existing plant - which has grown steadily since 2001 as a contract electroplating facility - offers a good insight into the world of sophisticated electroplating production. Like many companies in the gold town of Pforzheim, Jentner's roots go back to the town's strong jewelry industry, which required and still requires flawless, high-quality surfaces.

Jentner Managing Director Chris Jentner expects the electroplating industry to develop at two speeds in future. Those who digitize their production will make faster progress than those who do not . While the new building is still waiting to be completed next autumn with scaffolding, the existing plant - which has grown steadily since 2001 as a contract electroplating facility - offers a good insight into the world of sophisticated electroplating production. Like many companies in the gold town of Pforzheim, Jentner's roots go back to the town's strong jewelry industry, which required and still requires flawless, high-quality surfaces.

Today, functional coatings are electroplated for the electrical, medical, high-frequency and aerospace industries, among others - in classic manual electroplating plants or barrel systems for bulk materials. In the creative sector, the focus is on decorative coating. Here, as always, the company is dedicated to the beauty and color variety of products. Coins are suspended from a rack and coated with a layer of precious metal. Other parts shimmer in gold or silver and have matt or shiny surfaces. Some of the products are made for jewelers and goldsmiths, while others go to the sanitary industry - for example, fittings that are first de-chromed and then coated with matt gold.

Separate from the actual production, employees in the so-called technical electroplating department are busy assembling racks for functional coating, which are then immersed in the appropriate baths by electroplaters. The materials that are electrochemically deposited here range from gold, silver and platinum to ruthenium, nickel, copper and chrome. In addition, there are countless mixed forms that are applied to all types of substrates, such as steel or copper and increasingly also aluminum. A frame with shiny, silvery raw components for brain surgery is currently being immersed in a bath in which chromium III passivation takes place. The coating of the surgical instruments must be flawless as well as technically and visually flawless.

The creative area of contract electroplating is dedicated to both the sanitary sector and the decorative coating of jewelry for jewelers and goldsmiths

The creative area of contract electroplating is dedicated to both the sanitary sector and the decorative coating of jewelry for jewelers and goldsmiths

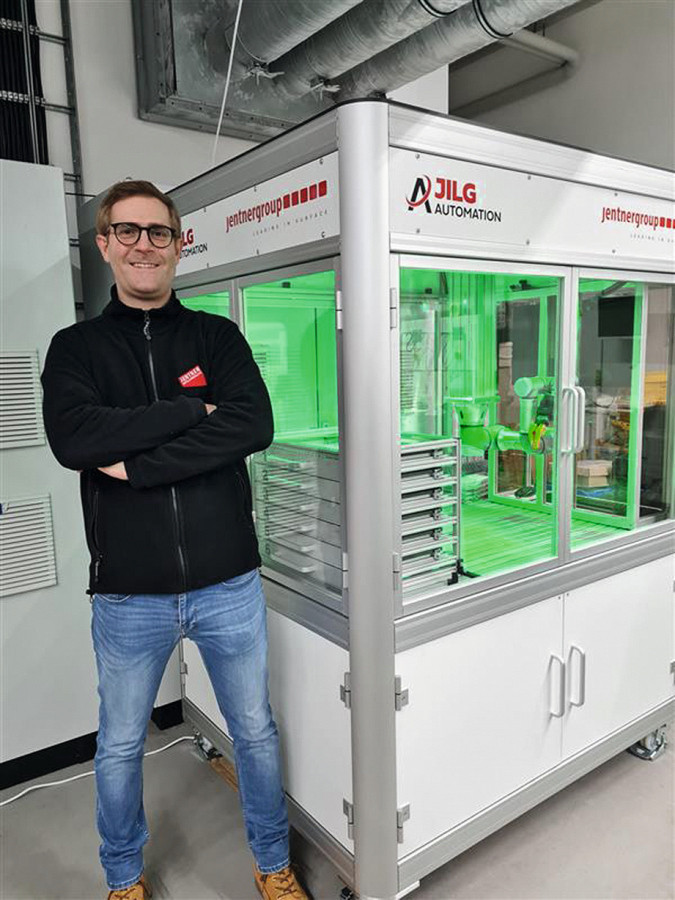

Production in the existing electroplating shop is responsible and modern: For example, there is the three-meter-high exhaust air scrubber, which cleans the vapors extracted directly at the baths before they leave the building. But there is also a so-called cobot, a collaborative robot that monitors the quality of medical technology products in a glass cell. This requires 100% quality control, which means that the products are photographed and checked for defects before and after coating: A complicated procedure that is still in test mode and requires several images and special lighting conditions in each case for correct recording, as Chris Jentner explains.

From contract electroplating to IT operations

Employees carrying out a chemical analysis on one of the baths in the electroplating shopThe47-year-old has managed the electroplating shop since 1999 and is a pragmatic doer who trained as an industrial clerk and electroplater. At the same time, the electroplating manager is also an industry visionary who has set himself the goal of transforming his company "from a traditional contract electroplating business into an IT company that operates a contract electroplating business" - a task for which the Jentner Team Technology was set up specifically, which works together with Pforzheim University and participates in international research projects in the field of digitalization.

Employees carrying out a chemical analysis on one of the baths in the electroplating shopThe47-year-old has managed the electroplating shop since 1999 and is a pragmatic doer who trained as an industrial clerk and electroplater. At the same time, the electroplating manager is also an industry visionary who has set himself the goal of transforming his company "from a traditional contract electroplating business into an IT company that operates a contract electroplating business" - a task for which the Jentner Team Technology was set up specifically, which works together with Pforzheim University and participates in international research projects in the field of digitalization.

Together with Heike Klaus-Karwisch, Chris Jentner guides visitors through production in a white shirt with the Jentner logo. According to Jentner, the aim of the change process in the company is also to penetrate even further into the area of high-priced and high-quality coatings. The company is targeting technical rack products for the aerospace, medical and renewable energy sectors. "Connectors and contacts with low voltage and high amperage for electromobility, larger power plants and fuel cells," he specifies.

The new building, for which the company is investing 15 million euros, will be the setting for the electroplating of these products. A considerable sum for a company that is part of an industry that generates annual sales in the single-digit billion range. It almost seems as if the entrepreneur has coordinated the key data of the planned German development with his plans in order to be successful with the project. After all, the intended transparency, sustainability and resource efficiency of the new production facility fits in well with the development trends in society as a whole - digitalization, which is increasingly breaking new ground, and climate neutrality, which Germany is aiming for by 2045.

Chris Jentner and a cobot (collaborative robot) for testing medical technology components in technical electroplating. Cobots to become even more important in the company in future

Chris Jentner and a cobot (collaborative robot) for testing medical technology components in technical electroplating. Cobots to become even more important in the company in future

One of the current 65 employees in the electroplating department. The number of employees will be increased for the new buildingWhilethe electroplating technology of the past was still largely based on experience, digitalization at Jentner will enable process control in the future, which will allow the traceability of errors and reduce waste through pattern recognition. If everything goes according to plan, pattern recognition will use machine learning to correlate unfavorable parameters such as too old degreasing, too high temperatures or unfavorable humidity with the coating quality. While human perception is only able to juggle around 3-5 parameters, pattern recognition can keep an eye on several thousand pieces of data per rack. Algorithmic calculations then supplement the electroplater's experience.

One of the current 65 employees in the electroplating department. The number of employees will be increased for the new buildingWhilethe electroplating technology of the past was still largely based on experience, digitalization at Jentner will enable process control in the future, which will allow the traceability of errors and reduce waste through pattern recognition. If everything goes according to plan, pattern recognition will use machine learning to correlate unfavorable parameters such as too old degreasing, too high temperatures or unfavorable humidity with the coating quality. While human perception is only able to juggle around 3-5 parameters, pattern recognition can keep an eye on several thousand pieces of data per rack. Algorithmic calculations then supplement the electroplater's experience.

These are ambitious goals, the realization of which could massively reduce costs and emissions. After all, resources and energy are saved with fewer rejects. At the same time, the traceability of all production steps quickly provides clarity in the event of complaints. Jentner's digital electroplating could thus become a blueprint for the industry, as unclear causes of errors result in high costs in German electroplating plants. Traceability would ensure clarity in liability issues.

Jentner wants to summarize the data collected in a digital production file that will be made available to the customer. The manager also envisages integrating upstream and downstream production areas into the digital process control in order to achieve production optimization and greater transparency for the entire production chain.

Focus on climate neutrality

Employees in the laboratory that develops and tests electrolytes, among other things.Thereare plans to develop digital twins for electrolytes in order to optimize them on the computerTheforthcoming technological development offers Jentner yet another decisive advantage: reporting thecarbon footprint of the production steps - indispensable information for the carbon footprint, with which industrial companies will have to disclose theirCO2 emissions in the future, as in a tax return. The carbon dioxide used for production will be part of the digital production file - and support customers on their path to climate neutrality.

Employees in the laboratory that develops and tests electrolytes, among other things.Thereare plans to develop digital twins for electrolytes in order to optimize them on the computerTheforthcoming technological development offers Jentner yet another decisive advantage: reporting thecarbon footprint of the production steps - indispensable information for the carbon footprint, with which industrial companies will have to disclose theirCO2 emissions in the future, as in a tax return. The carbon dioxide used for production will be part of the digital production file - and support customers on their path to climate neutrality.

But Jentner is not stopping there: He wants to recycle raw materials from electrolytes and is therefore currently involved in a corresponding project of the Central Innovation Program for SMEs (ZIM). "If I recycle gold, I have a bettercarbon footprint than if I use mined gold, which causes more pollution," says Jentner, highlighting the importance of recycling for thecarbon footprint. At the same time, metal recycling is a good business model for the company, which employs four chemists in the laboratory and also develops its own electrolytes or tests them on behalf of customers. Another digitalization tool could soon be used to optimize electrolytes: the so-called digital twin, which simulates electrolytes on the computer. The Jentner Group also sells anodes via Jentner Plating Technology GmbH and designs and sells small electroplating systems for laboratories, schools, industrial electroplating and goldsmiths.

The electroplating plant of the future is already taking shape in the new three-storey building, which will generate a lot of its own energy with solar cells on the roof: Through the large windows of the building, the electroplating plant with the crane tracks for the racks can already be glimpsed - a glass factory in the making. In the future, the new plant will coat technical racks in baths with up to 1000 liters of electrolyte. "I want maximum speed with perfect quality," is how Jentner puts his ideas into words and then describes the production process as it could look from the end of the year: After the goods are received, they are scanned and transported in blister packs by an automated guided vehicle system (AGV) to a so-called chaotic warehouse, where the goods are placed where they fit. Using a production-optimized sequence that is currently being programmed by the Jentner Technology team, the AGV picks up the goods at the right time and takes them to the electroplating shop. Production is supported by sensors that record production parameters, a GPS system to determine the position of the parts and cobots that help with assembly and ensure quality management. "We want to know everything," says Jentner, looking at the production data. And in view of the entrepreneur's plausible technological simulations, visitors are inclined to believe that he will succeed.

Sustainability also applies to mobility: At Jentner, the vehicle fleet is electrifiedToprotect the environment, the hall floor is first coated and then approved by TÜV. Meanwhile, part of the building serves as temporary storage for the numerous components of the new electroplating plant. The exhaust air system and electrical components on the second floor will take up almost the same floor space as the production itself. The currently empty rooms with their rough gray concrete walls will then house ventilation systems, as well as control cabinets, distribution boards and, last but not least, a sophisticated, state-of-the-art fire protection system and extinguishing water retention basin to ensure insurance cover. Jentner is also concerned about how waste water is handled in the new plant: "We work without waste water," he emphasizes. In a sophisticated system, every drop of water is recirculated using vacuum evaporators and UV systems to destroy the cyanides. The electroplaters from Goldstadt are similarly efficient in their use of heat, which remains in the building via waste heat recovery and storage using a heat pump and is reused for heating the halls. Energy is provided by the company's own combined heat and power plant. The employees have also been taken into consideration: an in-house restaurant offers healthy food. Lockers, showers and laundry facilities also ensure pleasant working conditions.

Sustainability also applies to mobility: At Jentner, the vehicle fleet is electrifiedToprotect the environment, the hall floor is first coated and then approved by TÜV. Meanwhile, part of the building serves as temporary storage for the numerous components of the new electroplating plant. The exhaust air system and electrical components on the second floor will take up almost the same floor space as the production itself. The currently empty rooms with their rough gray concrete walls will then house ventilation systems, as well as control cabinets, distribution boards and, last but not least, a sophisticated, state-of-the-art fire protection system and extinguishing water retention basin to ensure insurance cover. Jentner is also concerned about how waste water is handled in the new plant: "We work without waste water," he emphasizes. In a sophisticated system, every drop of water is recirculated using vacuum evaporators and UV systems to destroy the cyanides. The electroplaters from Goldstadt are similarly efficient in their use of heat, which remains in the building via waste heat recovery and storage using a heat pump and is reused for heating the halls. Energy is provided by the company's own combined heat and power plant. The employees have also been taken into consideration: an in-house restaurant offers healthy food. Lockers, showers and laundry facilities also ensure pleasant working conditions.

Momentum towards climate neutrality

"At some point, we will no longer be able to sell S-Classes to China," says Jentner, assessing Germany's economic future, adding: "Instead, it could be environmentally friendly technology." Europe and Germany are pioneers in the world when it comes to climate protection. In addition, there is now a momentum in business and industry that will sooner or later encourage manufacturing companies to adopt climate-neutral production, he explains. As an example, he cites a large German technology company that has already been climate-neutral for two years and is increasingly demanding the same from its suppliers. However, customer expectations now go even further: the Code of Conduct (CoC), to which Jentner is also committed, requires companies to no longer use raw materials from conflict regions. According to Jentner, this applies to rhodium from Russia, for example.

If this trend continues, the change at Jentner will also reflect the changes in the industry as a whole. And possibly faster than expected. So it's high time for electroplating companies to assess their business concept for future viability.

Click here for the interview with Chris Jentner.

INFO

C. Jentner GmbH

Turnover: 12 million euros

Employees: 65, which will be successively increased to

to a maximum of 100

Trainees: 3-5 per year, commercial clerks and surface coaters

Batch sizes: from 5 to 5 million pieces

Throughput per day: 80 racks with substrates