New alliances

There are many links between Ukraine and Russia. Many Ukrainian families have relatives in Russia and many in the Donbass region are Russian-speaking. However, Ukrainians are now increasingly keen to forge closer ties with Europe. Ukraine has applied to join the EU - but this will take several years, if it happens at all.

Ukraine still has many historical links with Russia, and one of them is the gauge of its railroad system, which is 1520/1524 mm, while in Europe as a whole the gauge is 1435 (with the exception of Ireland, Portugal, Spain and Finland, which all have a slightly larger gauge). However, Ukraine is now planning to convert its railroad lines to the European gauge. Technically, converting from a larger gauge to a smaller gauge is not too difficult and much easier than converting from a smaller gauge to a larger gauge. Figure 1 shows how the wagon (in this case a sleeping car) needs to be raised at the boundary when one set of bogies (gauge1) is replaced by another set - in this case from 1524 to 1435mm.

At present, it seems unlikely that Russia will conquer the whole of Ukraine. But looking at the map, one could imagine a Russian annexation of the entire Ukrainian coastline all the way to Moldova, where there is already a Russian puppet government in Transnistria. This would turn Ukraine into a landlocked country where rail transportation would be the only means of exporting wheat and other agricultural products. The change of gauge thus has both symbolic and practical significance. Moldova is not the only country currently under threat from Moscow. In recent weeks, there have been new tensions and Russian threats towards Lithuania, which has imposed EU sanctions on trade with Kaliningrad. Peace seems a long way off, but we should not give in to Russian aggression.

Technology news from Russia

Fig.2: The new Lada Granta Classic 2022 model lacks many safety features I always feel guilty when I have no technical developments to report from Russia. But the Russian state-owned company AvtoVAZ, the parent company of Lada, recently announced the launch of a new model - the Granta "Classic". When Russia invaded Ukraine, the French giant Renault decided to sell its 68% stake in Lada - for the enormous price of - just 1 ruble! In fact, Renault has the option to buy back its stake at any time within the next six years. Figure 2 shows the new 2022 Granta Classic, which looks like many other small passenger cars. But the Western sanctions have hurt! The new model has no ABS, no airbag for the front passenger, no air conditioning, no traction control, only a traditional door lock (no remote) and no seatbelt pretensioner. You could say that this is perhaps a car from the 1990s? It has a 1.6 liter gasoline engine and a 5-speed manual transmission. The launch price is 760,000 rubles - about US$13,200. I'm not sure if it would be legal on German roads. M. Sokolov, president of AvtoVAZ, has stated that Lada is working with Russian suppliers so that the missing features can be sourced within Russia. I wonder how Russian car buyers will react?

Fig.2: The new Lada Granta Classic 2022 model lacks many safety features I always feel guilty when I have no technical developments to report from Russia. But the Russian state-owned company AvtoVAZ, the parent company of Lada, recently announced the launch of a new model - the Granta "Classic". When Russia invaded Ukraine, the French giant Renault decided to sell its 68% stake in Lada - for the enormous price of - just 1 ruble! In fact, Renault has the option to buy back its stake at any time within the next six years. Figure 2 shows the new 2022 Granta Classic, which looks like many other small passenger cars. But the Western sanctions have hurt! The new model has no ABS, no airbag for the front passenger, no air conditioning, no traction control, only a traditional door lock (no remote) and no seatbelt pretensioner. You could say that this is perhaps a car from the 1990s? It has a 1.6 liter gasoline engine and a 5-speed manual transmission. The launch price is 760,000 rubles - about US$13,200. I'm not sure if it would be legal on German roads. M. Sokolov, president of AvtoVAZ, has stated that Lada is working with Russian suppliers so that the missing features can be sourced within Russia. I wonder how Russian car buyers will react?

For Western car buyers - a trouble-free future ?

Fig. 3: The new Goodyear Air-free tireTheair-filled rubber car tire is about 130 years old. Since then there has been some progress - the so-called tubeless tire, and the so-called "runflats", which allow limited driving even after a puncture. These are fitted to some military vehicles. There have also been tires filled with a gas other than air. But today we are on the cusp of a completely new generation of airless car tires. Many of the world's leading tire manufacturers will soon be offering them for sale.

Fig. 3: The new Goodyear Air-free tireTheair-filled rubber car tire is about 130 years old. Since then there has been some progress - the so-called tubeless tire, and the so-called "runflats", which allow limited driving even after a puncture. These are fitted to some military vehicles. There have also been tires filled with a gas other than air. But today we are on the cusp of a completely new generation of airless car tires. Many of the world's leading tire manufacturers will soon be offering them for sale.

A Tesla Model 3 tested the new Goodyear tires on a test track in Luxembourg. Special plastic spokes support a thin, reinforced rubber tread. The spokes bend and deform as the car drives around the bends of the track. Figure 3 shows the new wheel. In Goodyear's laboratories, the tires are tested for 24 hours at a time under different loads and speeds, which equates to thousands of kilometers without interruption. Some spokes deform, some break, but the structures continue to function safely. The new spokes are made of high-strength resin in which fiberglass and composite rubber (for which Michelin has 50 patents pending) are embedded, creating a mesh structure that surrounds an aluminum wheel. In the long term, Michelin envisions an airless, cross-linked (i.e. "smart") tire that is 3D printed and made entirely from materials that can be melted down and recycled.

Are there any disadvantages to this new technology? Airless tires have a larger contact area with the road, which increases drag. This increased rolling resistance consumes more energy to propel the tires, which affects battery life and range. In addition, the stiffness of the plastic spokes transmits more vibrations to the suspension. Drivers will certainly notice a difference: South Korean company Hankook unveiled the latest version of its i-Flex NPT (Non-Pneumatic tire) in January. Smaller than a conventional tire, a honeycomb of interlocking polyurethane spokes is a breakthrough in coping with lateral and horizontal loads, according to the company. And in the future? Airless tires will have a higher price tag, at least initially. But the possibility of regular retreading and 3D printing could tip the scales. Perhaps, some experts speculate, consumers will no longer have to buy tires at all. Instead, they will get them for free and pay per kilometer, with sensors monitoring usage.

In the meantime, Michelin has been working with GM (General Motors) to refine its version. At first glance, the two products look very similar. From South Korea comes another version, that of Hankook.

Many different factors are driving this trend. E-cars with large and heavy batteries cause more tire wear than lighter fuel vehicles. There is a growing trend to use electric cars for longer hours per day, perhaps with several different drivers during a 24-hour day. New car models are designed to be easily recycled, but today's rubber tires are almost impossible to recycle. In some cases they are shredded and used in road construction, but most simply end up in the trash. The new so-called "non-pneumatic" tires are designed to be easy to recycle. There's a saying in English "Re-inventing the wheel" and that's what's happening now. Just one more thing - could someone please tell the Russians that?

Electric cars and the tax problem

In the UK, an initial tax is payable on the purchase of a new car. For a very small car this can be 30 euros. For the largest vehicles, such as an R8, it is around 2500 euros. In all subsequent years, the tax is 180 euros. Petrol or diesel is then taxed at around 0.65 euros per liter. Together, these taxes generate annual revenue of around 30 billion euros for the British government. There are currently around 500,000 pure electric vehicles (excluding hybrids) in the UK, and the number has doubled in 2020 and 2021. The government loses tax on each of these vehicles because they do not use fuel. A VAT rate of 5% is levied on electricity. So every year, as the number of electric cars grows, the government loses more tax revenue. How should this be replaced? The UK government is still undecided, but it is proposed that every electric car be fitted with a satellite tracking device. The simplest method would be to charge by the kilometer, but it would also be possible to charge more or less depending on the time of day or whether the car is on a main road or a freeway. I don't know how other European countries deal with this problem, and it could become even more difficult when driving from one country to another. Will there be an EU solution to this problem, and if so, what will happen to non-EU members? And how would the tax be collected? Perhaps every month? I am not an expert in this field, but as far as I know, a vehicle equipped with a satellite tracking device sends out a signal. If this vehicle is parked in an underground garage, for example, this signal can no longer be detected. I wonder if criminals, knowing about the shielding, would be able to hide the signal of their car or truck - and thus evade the tax? Could this be done by carefully positioning a copper mesh?

Rolls-Royce - World famous with growing German roots

Fig. 4: Stefan Hoeller, CEO, shows a small hydrogen electrolyzer unitInEngland, you can call anything from a vacuum cleaner to a computer a "Rolls-Royce". In other words, it is a term used to describe excellence. In fact, Rolls-Royce Motors has been wholly owned by BMW for over 20 years. The cars are still built in England, but much of the mechanics come from BMW or use its designs. By contrast, Rolls-Royce itself, one of the world's leading manufacturers of gas turbines, is a completely independent company. The company has wisely recognized that aircraft powered by gas turbines that burn kerosene are likely to become obsolete in around 15 years' time. The company has therefore been focusing on other areas for many years. One of its greatest successes is the alliance with MTU Friedrichshafen. Traditionally a manufacturer of diesel engines (the company was founded by the Maybach family), it now also produces fuel cells designed to power ships and other large mobile devices. Now a new member, also from Germany, has joined the Rolls-Royce family. Hoeller Electrolyzer GmbH, based in Wismar (Germany), claims to manufacture the world's most efficient proton membrane water electrolysis systems for hydrogen production. Their "Prometheus" electrolyzers are designed for outputs from 1kW to 1MW. Figure 4 shows Stefan Hoeller with a small electrolysis unit.

Fig. 4: Stefan Hoeller, CEO, shows a small hydrogen electrolyzer unitInEngland, you can call anything from a vacuum cleaner to a computer a "Rolls-Royce". In other words, it is a term used to describe excellence. In fact, Rolls-Royce Motors has been wholly owned by BMW for over 20 years. The cars are still built in England, but much of the mechanics come from BMW or use its designs. By contrast, Rolls-Royce itself, one of the world's leading manufacturers of gas turbines, is a completely independent company. The company has wisely recognized that aircraft powered by gas turbines that burn kerosene are likely to become obsolete in around 15 years' time. The company has therefore been focusing on other areas for many years. One of its greatest successes is the alliance with MTU Friedrichshafen. Traditionally a manufacturer of diesel engines (the company was founded by the Maybach family), it now also produces fuel cells designed to power ships and other large mobile devices. Now a new member, also from Germany, has joined the Rolls-Royce family. Hoeller Electrolyzer GmbH, based in Wismar (Germany), claims to manufacture the world's most efficient proton membrane water electrolysis systems for hydrogen production. Their "Prometheus" electrolyzers are designed for outputs from 1kW to 1MW. Figure 4 shows Stefan Hoeller with a small electrolysis unit.

Not just Rolls-Royce

Across Europe, there are many other multinational partnerships involved in the "hydrogen economy". German giant Schaeffler is working with British company Johnson Matthey and other European partners to develop its own design for a hydrogen electrolyzer. Schaeffler's metal forming and coating expertise is a key element in this partnership. Schaeffler and Symbio have recently founded a new company, Innoplate, which will manufacture bipolar electrodes in Hagenau (FR), mainly for fuel cells but also for hydrogen electrolyzers. The company plans to produce 50 million bipolar plates per year when fully operational. This is all part of the H2-Giga project, which is being funded by the BMBF with 500 million euros. There are so many exciting developments related to hydrogen today, for industry, for our homes, for cars and trucks and even for airplanes. One such German-British project is the link between Bosch and the British company Ceres Power(www.ceres.tech).

Fig. 5: View of the Elcogen fuel cell production lineIncollaboration with Ceres Power, Bosch says it is close to manufacturing a solid oxide fuel cell (SOFC) based on Ceres technology for industrial purposes - particularly for office buildings and data centers - and will invest 400 million euros to build a plant capable of producing 200 MW of SOFCs by 2024. Ceres Power also has license agreements with South Korea's Doosan, as well as agreements with China's Weichai, Japan's Miura, Honda, Nissan and US Cummins Diesel. But perhaps the most exciting breakthrough is the development of the reversible solid oxide cell. It can be operated both as a fuel cell and as a water electrolyzer, making it a key technology in the hydrogen economy, capable of producing hydrogen that can then be stored to produce electricity when needed.

Fig. 5: View of the Elcogen fuel cell production lineIncollaboration with Ceres Power, Bosch says it is close to manufacturing a solid oxide fuel cell (SOFC) based on Ceres technology for industrial purposes - particularly for office buildings and data centers - and will invest 400 million euros to build a plant capable of producing 200 MW of SOFCs by 2024. Ceres Power also has license agreements with South Korea's Doosan, as well as agreements with China's Weichai, Japan's Miura, Honda, Nissan and US Cummins Diesel. But perhaps the most exciting breakthrough is the development of the reversible solid oxide cell. It can be operated both as a fuel cell and as a water electrolyzer, making it a key technology in the hydrogen economy, capable of producing hydrogen that can then be stored to produce electricity when needed.

Bosch already operates 50 SOFC pilot plants at its own locations in Bamberg, Homburg, Renningen, Salzgitter, Schwieberdingen, Stuttgart-Feuerbach and Wernau, as well as at customers such as Stadtwerke Bamberg. This SOFC plant supplies the surrounding area with electricity and the heat is used in a nearby bakery. The heat generated by the reaction is around 200 °C, making it ideal for district heating applications. Bosch forecasts a market worth around 20 billion euros by 2030.

Bosch-Ceres is not the only company developing reversible fuel cells. Other European competitors include Elcogen in Estonia, which has been developing a reversible fuel cell design for several years. It is aimed at renewable energy storage and was introduced on the basis of an EU-funded project that was integrated into a "Smart Energy Hub" in Turin, Italy. Elcogen claim that their fuel cells operate at a lower temperature (650°C) and with a higher efficiency (> 74%) than any of their competitors. They also claim a lifetime of 40,000 hours and a capital cost of €500/kW. Figure 5 shows part of the production line. Earlier this year, Elcogen signed a contract for a 200 MW reversible fuel cell stack to be installed in a nuclear power plant in South Korea. This will enable so-called "load leveling", i.e. the use of surplus electricity, e.g. at night, The company has several other such contracts. There are a number of other SOFC companies in Europe and elsewhere, such as Schlumberger New Energy, which has a very similar plan and is working with the CEA and industrial partners to create a new company Genvia around reversible SOFCs in Grenoble (FR).

Transportation and storage of hydrogen

Unfortunately, hydrogen is not easy to transport or store. It can be compressed or liquefied at very low temperatures. However, there are several promising new technologies where it is absorbed into a solid - I have written about this in the past. Germany seems to be leading the way in an alternative technology - LOHC - Liquid Organic Hydrogen Carriers. Hydrogenious LOHC GmbH in Erlangen is in talks with oil producers in the Middle East to produce hydrogen there and transport it to Europe using Hydrogenious technology. Another exciting idea is the use of their technology for ship propulsion systems - ships powered by hydrogen fuel cells. Galvanotechnik magazine has readers worldwide. However, I'm not sure if Vladimir Putin is among them. There are so many exciting developments in hydrogen technology - but I'm not sure it's good news for Russia.

Robots march forward

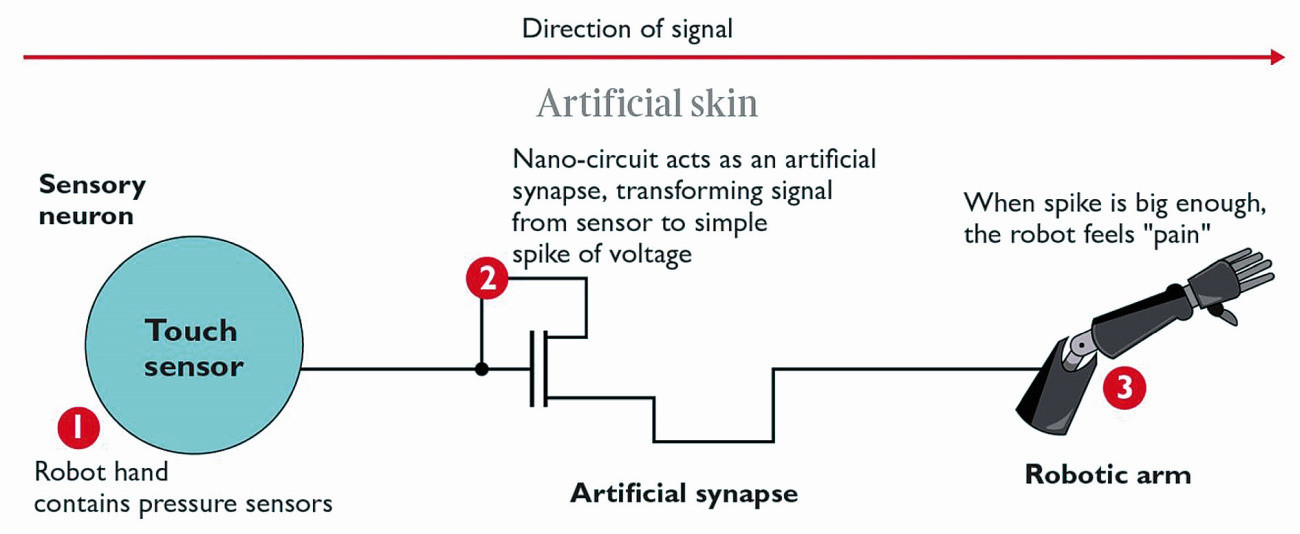

Robots can already perform the most amazing tasks. But there's one thing most robots lack: Feedback. How can the robot know if it's doing what it's supposed to do? Scientists in Glasgow have developed a synthetic skin that can feel "pain", which could one day give robots an "almost human" sense of touch. The electronic skin, which was developed at the University of Glasgow, is modeled on the human nervous system. The information is partially processed in tiny printed circuits contained in the skin itself, mirroring the way tactile sensations are perceived by human fingertips. This should make the system more sensitive and responsive than other synthetic skin systems, according to the inventors, while drastically reducing the power consumption required to operate the technology. According to Dr. Fengyuan Liu of the university, a co-author of the research paper, "this could be the basis for more advanced electronic skin in the future, allowing robots to explore and interact with the world in new ways, or to build prosthetic limbs that have near-human touch sensitivity." Equipping robots with something like a sense of touch is seen by experts as key to increasing their versatility.

Tactile feedback allows humans to adjust their grip when touching objects of different sizes and textures. A robot with a similar ability could be able to switch quickly between everyday tasks - from pouring a liquid from a heavy glass bottle to picking up a delicate piece of soft fruit. More dexterous robots could be used in industry to handle hazardous materials, in space exploration or in surgery. The new system consists of an articulated, human-shaped robotic hand (see image above) covered with a flexible plastic and containing a network of pressure sensors.

When a sensor is touched, its electrical resistance changes - a small change corresponds to a light touch, while a stronger touch causes a greater change in resistance. This is intended to mimic the way sensory nerve cells work in the human body. In previous generations of electronic skin, all this information was passed on to a computer, which processed it. In the new system, a circuit built into the skin acts as an artificial synapse - a replica of one of the sites in the human body where electrical impulses are transmitted from one nerve cell to another. The artificial synapse refines the signal sent by the pressure sensor and converts it into a simple voltage spike, the frequency of which varies depending on the amount of pressure applied to the skin. "The data is partially processed in the skin itself to extract relevant information," says Professor Dahiya, the team leader.

When the tension spike reaches a certain threshold, it triggers a reaction. In this case, the robotic hand will recoil from a sharp sting to the center of its palm. Dr. Dahiya explains: "The process of responding to touch is significantly accelerated as less computation is required. We believe this is a real step forward in our work to create large-scale printed electronic skin that is capable of responding appropriately to stimuli."

"Neuro-inspired electronic skin for robots" Fengyuan Liu et al, Science Robotics, 8 Jun 2022. vol 7, issue 67, DOI: 10.1126/scirobotics.abl7344