The current hot topics of sustainability, climate neutrality and energy saving in surface coating were discussed. The presentations highlighted approaches that can be used to optimize various process steps, reduce consumption, saveCO2 or avoid substances regulated by environmental and chemical policy. Sessions 2 and 7 also offered news from the fields of pre- and post-treatment and component cleaning.

Entrepreneur Forum Management meets Surface Integrated management systems (IMS) are an essential component of sustainability concepts. Andreas Redaoui, TopQM-Systems AG, recommends using ISO standards according to the "high-level structure" as a tool. It should be possible to measure the effectiveness of each process, for which key figures are very suitable. Companies can define key performance indicators themselves and use them to evaluate their processes. The data collected for ISO 14001 can also be used to establish a company's corporate carbonfootprint(CCF). The data collection can be individually adapted to the processes with tools from Office 365 and makes the evaluation much easier.

In a relaxed discussion, Dr. Sarah Schmitz, Delta Engineering Chemistry GmbH, and Astrid Krug, C + C Krug GmbH, presented a new frame insulation with Plastinol. Plastinol insulation lasts longer than conventional PVC-based insulation. Plastinol is manufactured without phthalates and other harmful components, using bio-based ingredients and renewable raw material sources. Another advantage of plastinol insulation is that significant energy savings can be made in frame construction because plastinol gels faster. Sustainable, climate-neutral and energy-saving coating Before components can be coated, the surface must be thoroughly degreased and cleaned. Olav Schulz, SLCR Lasertechnik GmbH, presented a sustainable SLCR laser cleaning process for bulk solids. The energy of the laser is absorbed and the contaminants evaporate. If desired, surfaces can be roughened and, depending on the material, the surface can also be activated. A major advantage is that no chemical cleaning agents or abrasives are required. However, the component surfaces can reach temperatures of up to 147 °C. Tests have shown that no structural changes occur in the metal. An industrial application for bulk goods is planned for 2025, in which the laser-cleaned parts will then be electroplated.

Christian Kurrle, Umicore Galvanotechnik GmbH, explained the advantages of platinum-coated titanium anodes over conventional lead anodes. The platinum-coated titanium anodes can be used for many electrochemical processes, including waste water treatment, electroforming or chlorine production. There are no by-products that have to be disposed of at high cost. In addition, the energy required during electrolysis is lower, reducing the company'scarbon footprint. BAFA subsidies are recommended for the investment of platinum-coated titanium anodes to replace lead anodes. Up to 40% of the investment is subsidized and up to a maximum of 300,000 euros over 3 years.

Rising energy costs are causing profits to plummet. Using the example of sealers, Dr. Michael Schem, MacDermid Enthone Industrial Solutions, showed how operating costs can still be kept within limits and even reduced by varying the concentration, treatment and drying time. He gives the tip of moderately lowering the drying temperature, although the goods must always be completely dry in order to maintain consistently good quality.

Removing chromium(III) ions and chromium(III) complexes from wastewater is challenging, as Laurens Wessels, MacDermid Envio Solutions, explained. Chromium(III) ions cannot be precipitated with sulphide, but only as hydroxide. Chromium(III) complexes must first be oxidized, which can be achieved with UV and H2O2. However, this process is very energy-intensive, which is why experiments were carried out using a membrane process. The permeate was then fed into the wastewater treatment system, while the concentrate had to be disposed of externally.

Dr. Jürgen Nagel from the Leibniz Institute of Polymer Research Dresden e.V. presented a pre-treatment-free modification of plastics for metallization. So-called core-shell particles are applied to the surface using the FloraSolv process during injection molding of the molded parts. If calcite is applied, pre-treatment in diluted acids such as hydrochloric or citric acid is sufficient, creating microcavities that can then be coated with electroless nickel as usual after palladium activation. Compared to conventional pre-treatment, the FloraSolv process saves time and costs for energy and disposal.

Marvin Wagner from BIA Kunststoff- und Galvanotechnik GmbH & Co. KG spoke about the chromium(VI)-free pre-treatment of plastics prior to electroplating

Marvin Wagner from BIA Kunststoff- und Galvanotechnik GmbH & Co. KG spoke about the chromium(VI)-free pre-treatment of plastics prior to electroplatingThe presentation by Marvin Wagner, BIA Kunststoff- und Galvanotechnik GmbH & Co. KG, also dealt with chromium(VI)-free pre-treatment of plastics prior to electroplating. Chromium(VI)-free can only be achieved with three additional treatment steps, which must be precisely coordinated with each other and with the materials. At present, multi-component plastics cannot be reliably electroplated in this way.

With the new, low-concentration zinc-nickel process, it is possible to significantly reduce the bath voltage. This enables energy savings of up to 25 % to be achieved. The process presented by Patrick Rio, Dipsol Europe GmbH, works at a zinc concentration of 5 g/L and with 0.8 g/L Ni and 60 g/L NaOH. Further advantages of the process are the low drag-out losses into the rinsing and then waste water. This saves both process and wastewater treatment chemicals. The complexing agent not mentioned in the presentation also has the advantage that no cyanide was detected in the process solution over a longer period of time. The low-concentration zinc-nickel electrolyte does not require any additional equipment, such as membrane technology or special anodes. Ordinary steel anodes are used.

Markus Ahr, Atotech Deutschland GmbH & Co KG, on the other hand, emphasized that the future of economical and sustainable zinc-nickel processes depends on the use of membrane anode technologies. This results in a stable process with very good productivity, in which zinc-nickel coatings for environmentally friendly corrosion protection are obtained with very good quality and an excellent gloss level. Only the use of membrane anode technology enables the complete recycling of rinsing water into the process solution, which saves on chemicals and significantly reduces disposal costs.

Bath optimization can save energy costs, as Marco Rösch, SurTec International GmbH, explained using examples. With newly developed builders and surfactants, the temperature in decoction degreasers can be reduced by up to 20 °C. For electrolytic degreasing, he recommends a two-component system consisting of KOH and an additive. Although KOH is more expensive, the switch from NaOH to KOH pays off because KOH can be used at a lower cell voltage and scorching is avoided.

Climate neutrality & energy and resource efficiency

An energy management system (EMS) can be used to reduce energy requirements and therefore costs, as Enrico Trautvetter from KBR Kompensationsanlagenbau GmbH reported. The EMS provides a detailed overview of the energy requirements in the various areas of production. Inefficient processes can be identified and converted accordingly. To reduce peak loads, the speaker recommended load management with alarms and notifications, which can save considerable costs. The EMS can also be useful for forecasting future energy requirements in order to optimize electricity contracts. With real-time monitoring of energy demand, problems can be detected and rectified at an early stage. Drying processes are very energy-intensive and, with rising energy prices, are cost drivers in the company. Reinhold Specht, Harter GmbH, recommends not only drying energy-efficiently with the innovative Airgenex heat pump-based condensation process, but also applying for state subsidies for the investment. He points out that from January 1, 2024, BAFA subsidies will require a positive decision before the system can be purchased and installed. Energy-saving drying is achieved through

- Heat recovery with heat pump technology

- Cover systems to prevent heat from entering the workshop

- blowing off without expensive compressed air

- state-of-the-art fan technology with adjustable speed and

- lower temperatures between 40 and 75 °C for gentle drying.

Coating thickness measurement is a profitable adjustment screw and ensures greater resource efficiency in the coating process. The process presented by Jörg Mülleneisen, OptiSense GmbH, is based on the photothermal measuring principle. A beam of light heats the surface of the coating. The cooling time depends on the coating thickness, which is measured by the detector. The mobile hand-held device can be used to check minimum coating thicknesses quickly and easily, for example in powder coating. Employees are sensitized and no longer apply layers that are too thick, which reduces coating costs.

Jan Sommer, Clean-Lasersysteme GmbH, explained the ablation principle of laser technology, which is used as an energy-saving surface pre-treatment. The coating and dirt layer are removed by absorption of the focused laser light and the resulting vapors are extracted. Grease films can be removed better than oil droplets. Short laser pulses (<100 ns) ensure very low thermal heating of the base material. Laser cleaning is less suitable for plastics. Laser technology can be used to clean with pinpoint accuracy. For example, sheet metal is only cleaned where it is subsequently welded.

The recovery of palladium from waste water brings both ecological and economic benefits for plastic electroplating. Marc Piepenbrink, BIA Kunststoff- und Galvanotechnik GmbH & Co. KG, described the development of a process with which almost 89% of the palladium can be recovered from activator rinses with 13 mg/L palladium. First, the palladium colloid is oxidized to convert it into the ionic form. Experiments were then carried out with various weakly acidic cation exchange resins and a strong base anion exchange resin, whereby all the resins tested absorbed the palladium and only a little of the tin also contained in the solution. Most of the tin was previously precipitated at pH 2. One liter of weakly acidic cation exchange resin can absorb 16 to 19.5 g of palladium, after which the loaded resin is sent for external recycling.

The experiences of Elke Moosbach, Moosbach & Kanne GmbH, and Elke Spahn, Gravitech GmbH, showed that simple changes, such as the timing of an analysis or separation of wastewater volume flows, make wastewater treatment safer and more efficient. This not only saves time, treatment chemicals and energy, but also costs. Analytics is essential in reducing theCO2 footprint.

Christian Deyhle, Qubus Planung und Beratung Oberflächentechnik GmbH, described what climate-neutral electroplating could look like in the future. Using the example of a combined rack and barrel system for the alkaline galvanizing of steel and zinc die-cast parts, he demonstrated that 50% energy savings can be achieved compared to an old system. The energy savings are possible through

- Use of low-temperature degreasing

- Shortening the anodic and cathodic cycles during electrolytic degreasing

- Adapting the process chemistry for improved conductivity in alkaline galvanizing

- Optimization of switch-on times to reduce peak loads

- Reduction of output when individual units are not in use (extraction, heating, lighting, etc.)

- Heat recovery from waste heat with heat pumps, whereby process and rectifier cooling should be included.

Lars Baumgürtel, ZINQ Technologie GmbH, provided answers and suggestions to the question of how circular transformation can succeed at company level. Product passports can be seen as drivers of circular business models. The data collection required for this should be used immediately for process control and regulation in order to reduce the company's ecological footprint. One particular question is who should pay for circular quality. Ultimately, it is in the interests of climate protection to use materials that ensure a longer shelf life. However, the price level must be adjusted for this, and sustainability must be affordable and rewarded.

The challenge of component cleanliness

The part on component cleanliness moderated by K. Zubert was opened by a presentation by Dr. Michael Flämmich from Vacom Vakuum Komponenten & Messtechnik GmbH. He gave an insight into the guideline "Mastering filmic contamination", which was developed by the Industrial Component Cleanliness Association. Both the German and English editions were taken into account. The guideline is primarily aimed at operators of parts cleaning systems, their operating personnel and users of measuring and testing technology. For example, the guideline provides information on how a component cleaning process chain can be set up and optimized, what requirements are placed on the cleanliness of components today and even goes one step further: Namely, how components should be constructed and designed to make a cleaning process simple and effective.

Construction instructions and building blocks for the ideal individual cleaning process, illustration of Dr. Michael Flämmich's presentation

Construction instructions and building blocks for the ideal individual cleaning process, illustration of Dr. Michael Flämmich's presentation

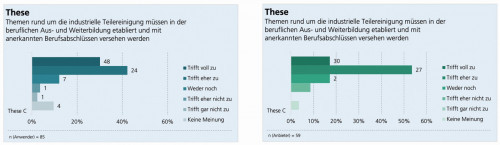

"In Germany, there is currently no formal training or further education in the field of industrial cleaning," complained Daniel Weile from Fraunhofer FEP, adding: "The current cleaning staff are all career changers." The cleaning process accounts for ten to 25 percent of the costs of a component. And around one in ten working hours is spent on the pre- and post-treatment of surfaces. It is therefore only logical that the Fraunhofer FEP has designed an in-service training course in this area and presented it in Berlin. This in-service training course is at DQR level 5, was funded by the Federal Ministry of Education and Research and is currently in the trial phase.

Opinion of users (left) and providers (right) on the integration of cleaning technology content in technical and scientific degree courses - from the presentation by Daniel Weile

Opinion of users (left) and providers (right) on the integration of cleaning technology content in technical and scientific degree courses - from the presentation by Daniel Weile

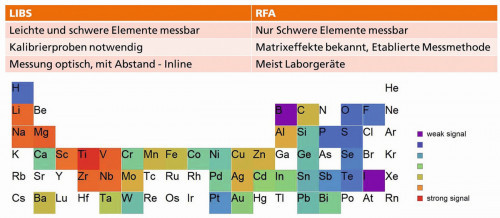

Andreas Hofmann's presentation dealt with optical inline measurement technology for detecting contamination. The system was developed by Fraunhofer IPM (Freiburg). The optical imaging method can be integrated directly into the production process. It detects particles quickly and reliably so that the process can be adjusted immediately, resulting in considerable savings. A number of optical technologies are used to achieve this, including fluorescence measurement technology, infrared reflection spectroscopy and laser-induced plasma spectroscopy.

Dr. Günter Schmauz gave practical examples of how typical impurities are removed using CO2 snow jets

Dr. Günter Schmauz gave practical examples of how typical impurities are removed using CO2 snow jets

Finally, this lecture block dealt with the dry and environmentally friendly cleaning of surfaces usingCO2 snow blasting. Speaker Dr. Günter Schmauz began his presentation by pointing out the discrepancy between the specifications. Ever-increasing quality requirements are offset by a steadily growing ban on chemicals such as solvents and restrictions on the consumption of resources (such as water and energy). As a solution, he presented carbon dioxide snow blasting as a potential alternative to the use of aqueous surfactant processes, for example.

Pre- and post-treatment

At the beginning of the lecture block, Prof. Dr. Guenter Schmitt (Institut für Instandhaltung und Korrosionsschutztechnik gGmbH) reported on electrochemical real-time monitoring of Cr(III)-based passivation for zinc-nickel coatings.

Later, Khavar Akbarova from the Technical University of Ilmenau gave a presentation on an activation process for the galvanic coating of passive nickel surfaces. Electroplated layers of nickel and chromium are usually used to protect components from corrosion. However, the nickel layers must be active for the subsequent chromium deposition (Cr(III)). Passive layers can form in the adjacent processing of already coated parts, which can lead to adhesion problems. A separate activation process is necessary. The presentation by Khvar Akbarova presented the results of a project that investigated and qualified various activation processes.

Laser-induced plasma spectroscopy, lecture by Hofmann: Optical, non-contact and fast material analysis without sample preparation

Laser-induced plasma spectroscopy, lecture by Hofmann: Optical, non-contact and fast material analysis without sample preparation

MacDermid Enthone Deutschland GmbH sent Can Akyil to Berlin, who presented the corrosion resistance of complex cast aluminum alloys through appropriate surface treatment. According to Akyl, aluminum is becoming increasingly important. Despite its comparatively low weight, it is strong enough to guarantee sufficient safety in aircraft and automobile construction. Two main types of corrosion are observed on aluminum components with passivated surfaces. These are uniform corrosion of the entire surface and filiform corrosion, which forms thread-like outgrowths under a protective layer. The main driving force for both types of corrosion is the electronegativity difference between the intermetallic elements consisting of alloy elements and the aluminum matrix. This leads to the formation of galvanic pairs that promote corrosion.

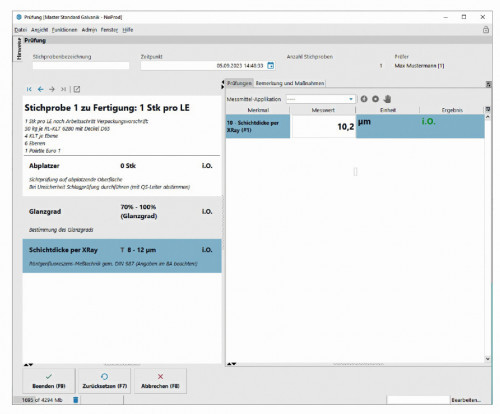

Example of a test protocol. The app from softec AG simplifies quality assurance and helps to avoid errors

Example of a test protocol. The app from softec AG simplifies quality assurance and helps to avoid errors

This topic was concluded with a presentation by Arnaud Kropp, Softec AG. A mobile app from the company helps to digitally record test results from quality assurance and errors that have occurred, thus shifting the documentation to the respective work step. The presentation also provided tips on how to improve the networking of hardware and software via interfaces. This has the advantage that values no longer have to be entered manually, thus avoiding transmission errors and saving time at the same time.