The affinity of heavy metals to sulphides, selenides and tellurides is well known. This principle is also used in wastewater treatment. Scientists at the Indian Institute of Technology Kharagpur, Indian Institute of Science Bengaluru and Christ University Bengaluru have synthesized 2D gadolinium telluride using the liquid phase exfoliation method for this purpose.

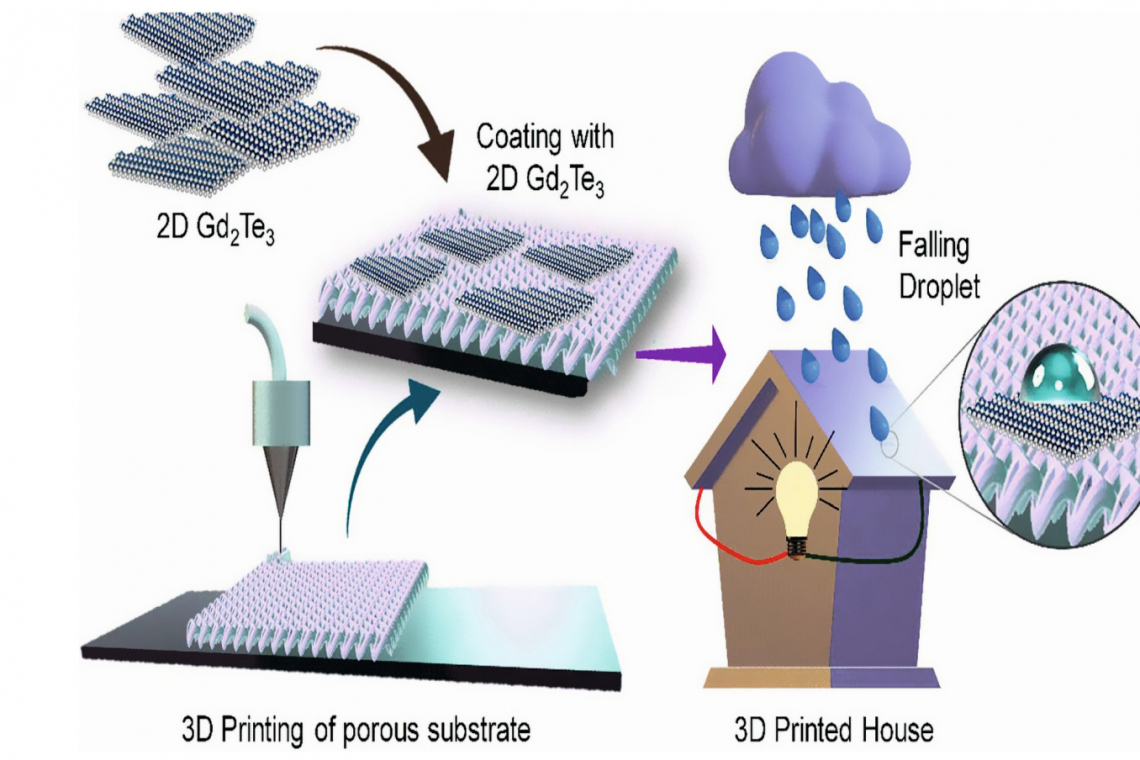

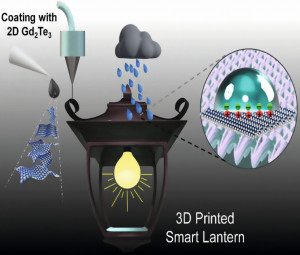

2D-telluride nanosheets have a large surface area and can be used as adsorbing filters. They have a greater affinity for heavy metals and other pollutants. In addition, 3D printing can be used to produce complex and customized filters at low cost. A 3D- Fig. 2: Composite architecture as an energy generator Printedporous polylactic acid substrate was coated with 2D-Gd2Te3 using a simple dip-coating process. The performance of the 2D-coated, 3D-printed composite was tested. Approximately 98% of the salts from the salt water were absorbed. A removal efficiency of 52 % was found for brackish water and 45 to 69 % for various organic dyes. The composite was able to adsorb 20 % of the bleaching powder from contaminated water. The 2D material improved filtration due to its morphological properties. The porous 3D-printed structure increased the contact time of the adsorbed salt water (Fig. 1).

Fig. 2: Composite architecture as an energy generator Printedporous polylactic acid substrate was coated with 2D-Gd2Te3 using a simple dip-coating process. The performance of the 2D-coated, 3D-printed composite was tested. Approximately 98% of the salts from the salt water were absorbed. A removal efficiency of 52 % was found for brackish water and 45 to 69 % for various organic dyes. The composite was able to adsorb 20 % of the bleaching powder from contaminated water. The 2D material improved filtration due to its morphological properties. The porous 3D-printed structure increased the contact time of the adsorbed salt water (Fig. 1).

The team used the composite architecture as an energy generator (Fig. 2). Water treatment plant manufacturers and environmental protection agencies can now explore the technology for better wastewater treatment with the added benefit of energy generation, the authors say.

https:// onlinelibrary.wiley.com/doi/abs/10.1002/adsu.202300321

Robots in contract electroplating

A good example of the benefits of advanced automation and robotics is the development of innovative robotic cells that enable fully automated electroplating. A fully automated system for electroplating racks was developed in collaboration between the customer - the surface coating specialist Collini from Dübendorf near Zurich - the automation company Roth Technik and the sensor specialist Baumer. The customer was looking for a space-saving solution for hanging small parts quickly and reliably on racks in order to place them in the electroplating bath.

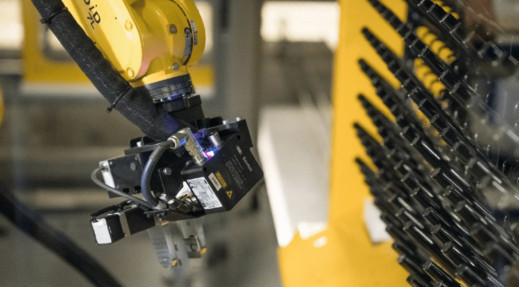

The conventional method of loading the racks by hand requires a lot of space and personnel, as several racks have to be loaded at the same time. The team began developing a fully automated and compact loading line. At the heart of the loading line are four robots that automatically load parts onto the empty hooks in the racks, with the biggest challenge being that no two racks are the same. The hook positions are not exactly in the same place on the welded racks, and some hooks may be bent or missing altogether. While this is not a problem with a manual system, it is a major challenge with robots that require precise positioning data. In addition, the large variety and high throughput of parts posed a further challenge. The ultra-compact OXM200 profile sensor, a simple but effective solution from Baumer, proved to be a key component in the effectiveness of the system. Mounted on the robot arm, the sensor detects the exact position of each hook as it moves through the rack and immediately reports this data back to the robot controller. With the help of a camera, the robot then picks up one part at a time from the carousel and hangs it on a hook. The robot uses the position coordinates previously recorded by the profile sensor to fine-tune the position of the part so that the profile sensor can guide the robot precisely and quickly on the electroplating rack. As the sensor has to provide excellent performance, a sensor had to be installed that recognizes and precisely measures very thin hooks not only in two-dimensional but also in three-dimensional space. Various camera-based systems and other laser-based scanners were tested, but the sensor was chosen (Fig. 3). Fig. 3: Robot, sensor and frame

Fig. 3: Robot, sensor and frame

The OXM200 sensor offers another major advantage: thanks to powerful, integrated measuring tools, the sensor outputs the measured values for the X and Z coordinates directly in mm, which significantly reduces the number of calculations in the controller. This resulted in less integration work in the software and enabled the project to be commissioned more quickly. With Power over Ethernet (PoE), only a single cable was needed to connect the sensor to the controller and supply it with power. The result: two robot cells enable a throughput of 15 million parts per year with minimal space requirements and eliminate the problems associated with a manual system.

https:// metrology.news/smart-profile-sensor-provides-guidance-to-electroplating-robot/

Leak-free tampon electroplating

Electroplating USA, based in Greenland, New Hampshire, USA, has developed a new patented system that is lightweight and portable. The so-called Drip Free System allows users to work safely without being exposed to toxic fumes and pollutants (Fig. 4). Fig. 4: So-called Leak Free Brush Plating System / Image: Electroplating USA

Fig. 4: So-called Leak Free Brush Plating System / Image: Electroplating USA

Traditionally, one of the most time-consuming aspects of brush plating is covering and sealing the system to prevent leaks. The new system eliminates the need for costly protective measures and extensive sealing procedures. The system includes a peristaltic pump for relatively precise solution delivery and a vacuum pump ejector that effectively collects excess solution for a safe and efficient plating process. This technology not only increases operator safety, but also protects the environment from toxic fumes and chemicals. The units are housed in robust, waterproof and shatterproof polypropylene rollover enclosures, ensuring durability and safety.

https://www.prweb.com/releases/electroplatingusa-unveils-leak-free-brush-plating-system-301994495.html;

https://electroplatingusa.com; US Pat. 11,342,710 B2

Tip: Market report on electroless coatings

Electroless plating or electroless plating is normally understood as an autocatalytic process in which metals and metal alloys are deposited on conductive and non-conductive surfaces, e.g. plastics, ceramics, glass, etc., which can then become decorative, corrosion resistant or conductive, depending on their final function. Based on the product type, autocatalytic plating technology is mainly divided into nickel plating, copper plating and composite plating. The so-called Autocatalytic Plating Technology research report provides information on this area of electroplating technology. The important segments of the market are evaluated in the report on the basis of their performance. The report offers an in-depth analysis of the market by providing the definition, application, and classifications. The SWOT (strengths, weaknesses, opportunities, and threats) analysis and strategies of each vendor in the market are included in the report. The report offers comprehensive insights into current industry trends, trend forecasts and growth drivers, especially in the automotive, chemical equipment, electronics and aerospace industries.

https:// www.openpr.com/news/3299584/autocatalytic-plating-technology-market-2023-industry